Tail gas treatment device and method for treating vapor extraction tail gas by utilizing mineralized garbage

A technology of gas phase extraction and mineralization of garbage, which is applied in the field of environmental restoration, can solve the problem of high cost of adsorbents, and achieve the effects of reducing secondary pollution, low energy consumption, and prolonging contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

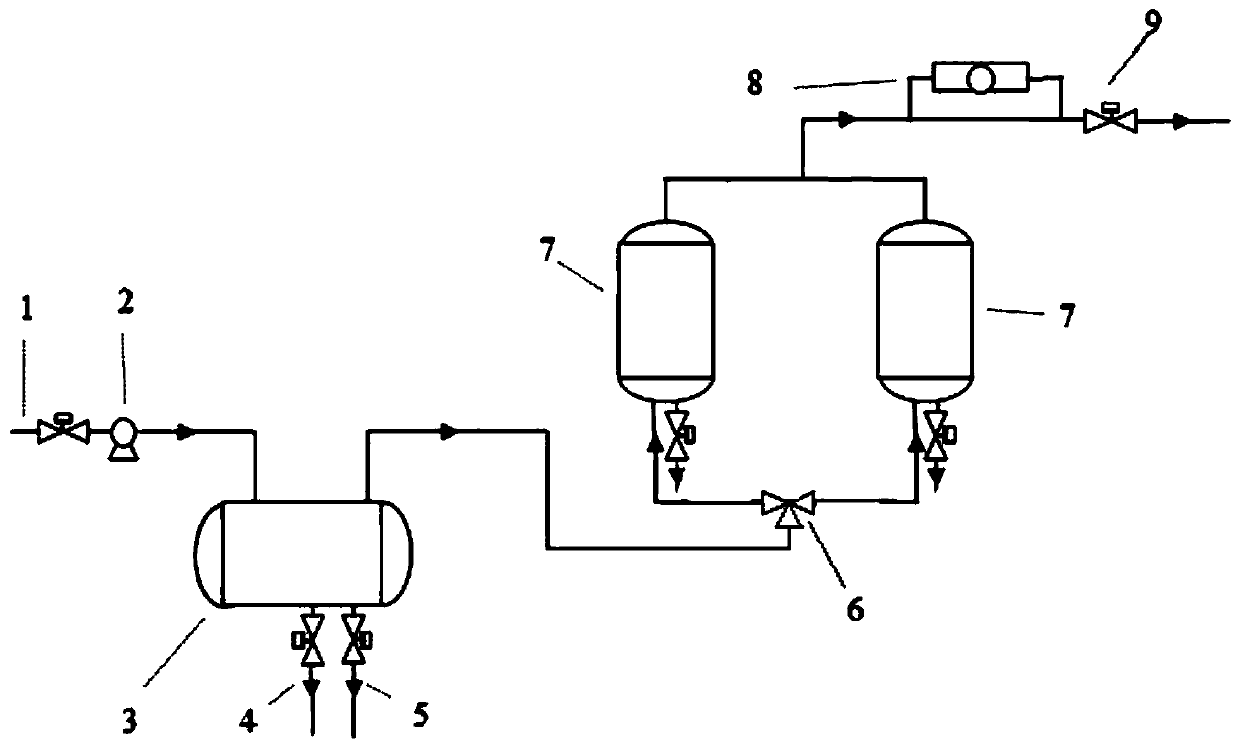

[0057] Specific embodiment 1, see figure 1 A tail gas treatment device for treating gas phase extraction tail gas using mineralized waste, including a sequentially connected separation unit, an adsorption unit and a monitoring unit.

[0058] The separation unit includes an intake pipe 1, a vacuum pump 2 and a three-phase separator 3, and the intake pipe 1 is provided with an intake valve. The inlet pipe 1 is a delivery pipe for transporting the exhaust gas generated by the gas phase extraction of soil. The inlet of the vacuum pump 2 is connected to the inlet pipe 1. The outlet of the vacuum pump 2 is connected to the inlet of the three-phase separator 3 through a pipeline, and the three phases are separated. The bottom of the device 3 is provided with a waste water discharge port 4 and a waste oil discharge port 5 .

[0059] The adsorption unit includes an adsorption tower, the filler in the adsorption tower is mineralized waste, the bottom of the adsorption tower 7 is provid...

specific Embodiment 2

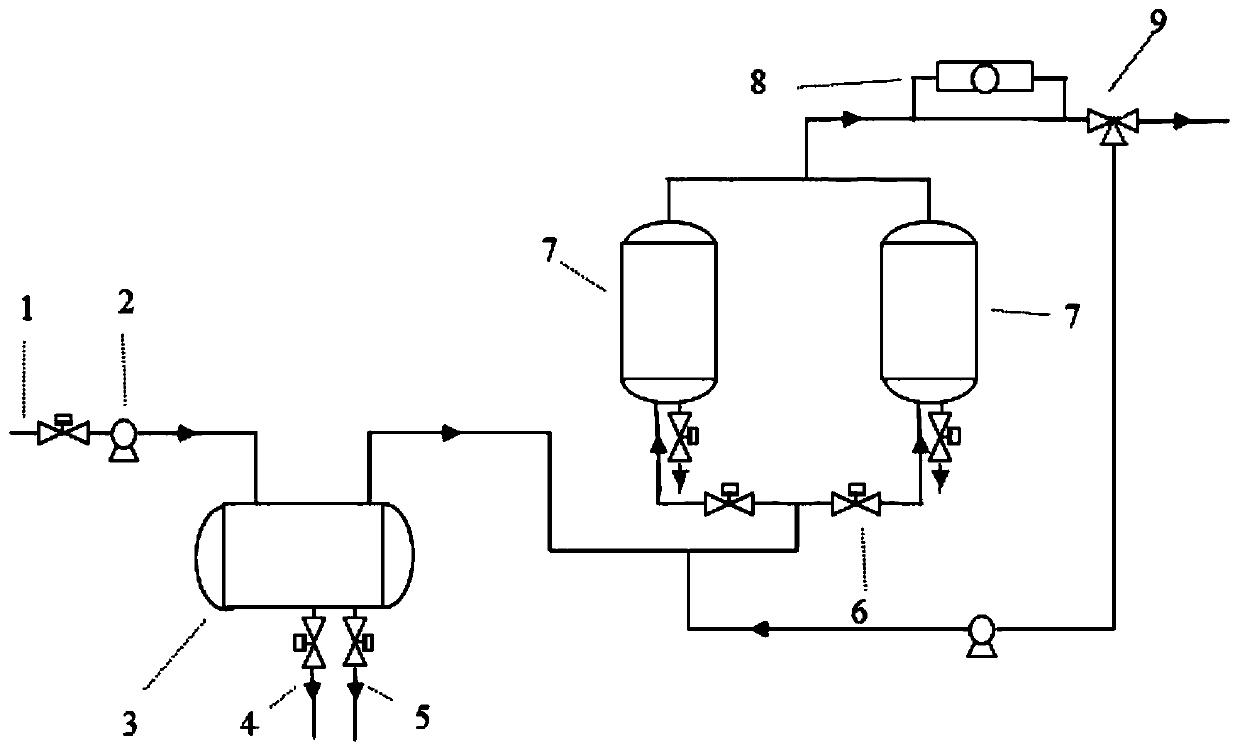

[0075] Specific embodiment 2, see figure 2 , On the basis of the specific embodiment 1, the exhaust valve 9 is a control valve 6 with one inlet and two outlets, one outlet of the control valve 6 communicates with the atmosphere, and the other outlet of the control valve 6 is connected to the main pipeline. In this patent, two or more adsorption towers can be operated at intervals. After one of the adsorption towers is fully adsorbed, the other is replaced for continuous operation of the device to ensure operating efficiency. At the same time, sufficient time is provided for the replacement of the packing in the adsorption tower to facilitate subsequent microbial treatment. .

[0076] An air pump is installed between the other outlet of the control valve 6 and the main pipeline. Easy to divert.

[0077] The method for using the device to treat tail gas comprises the following steps:

[0078] Step 1: Mineralized waste is filled into the adsorption tower in layers according t...

specific Embodiment 3

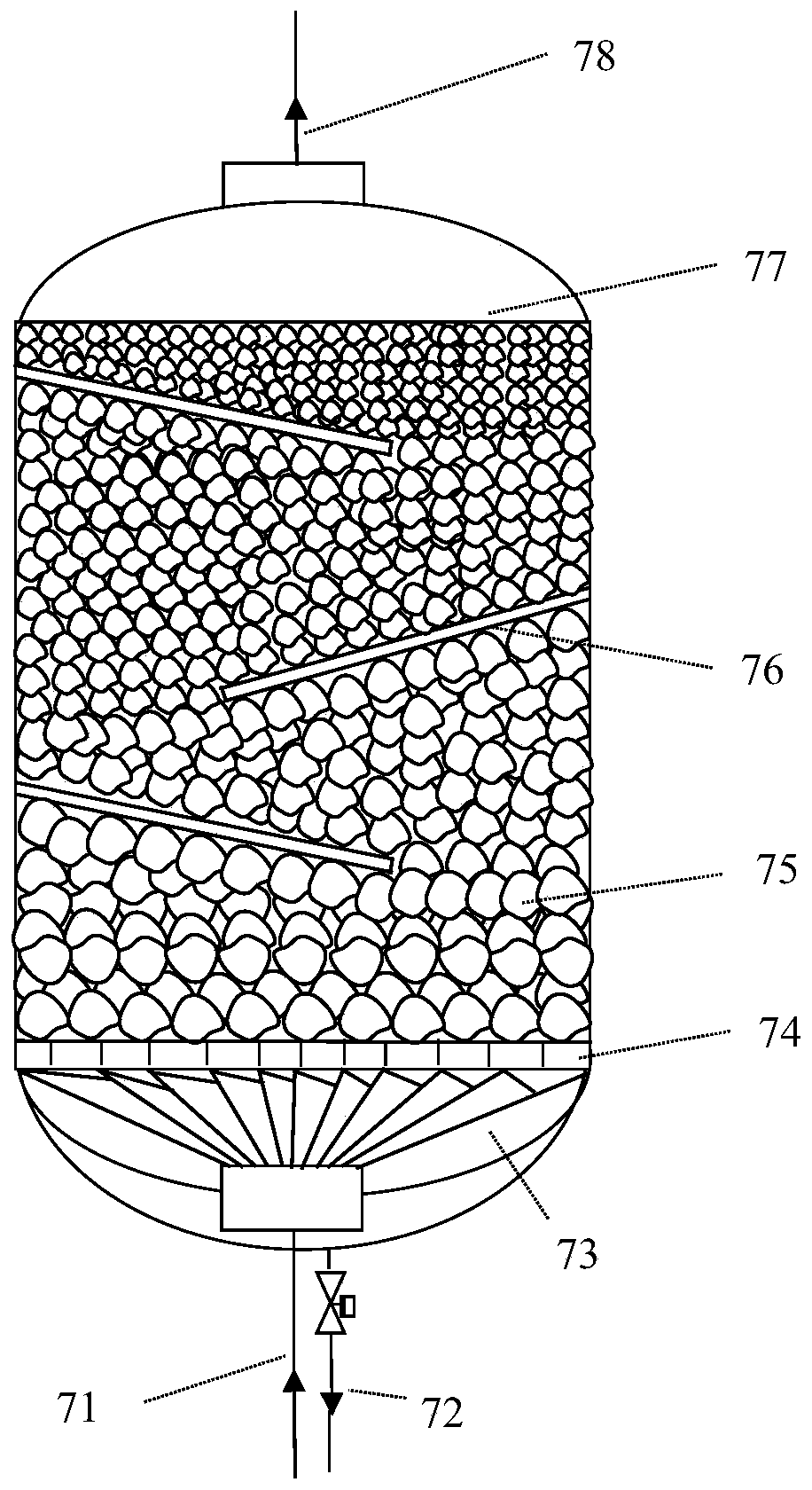

[0087] Specific embodiment 3, on the basis of specific embodiment 1 or 2, hollow plate 74, deflector 76 and limit baffle 77 are installed in the adsorption tower interior successively from bottom to top, between deflector 76 and the inner wall of adsorption tower There is a gap between them, and the gap is used as a channel for air flow; the filler is arranged between the hollow plate 74 and the limit baffle 77, and the limit baffle 77 is provided with air holes. The hollow plate 74 of this patent can not only provide support for the mineralized waste 75, but also can evenly distribute the diffused airflow to the interior of the adsorption tower. In addition to this, it also provides a path for falling debris. Through the limit baffle 77, it is possible to prevent the mineralized waste 75 from moving under the action of the airflow, while ensuring the circulation of the airflow.

[0088] The outer wall of the adsorption tower air inlet 71 is connected with the airflow diffusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com