Green, cheap and environment-friendly chemical mechanical polishing method for optical quartz glass

A technology of quartz glass and chemical machinery, applied in the direction of grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems of reducing product reliability, increasing production costs, increasing cleaning costs, etc., and achieves low flow rate and low concentration of components , the effect of short polishing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

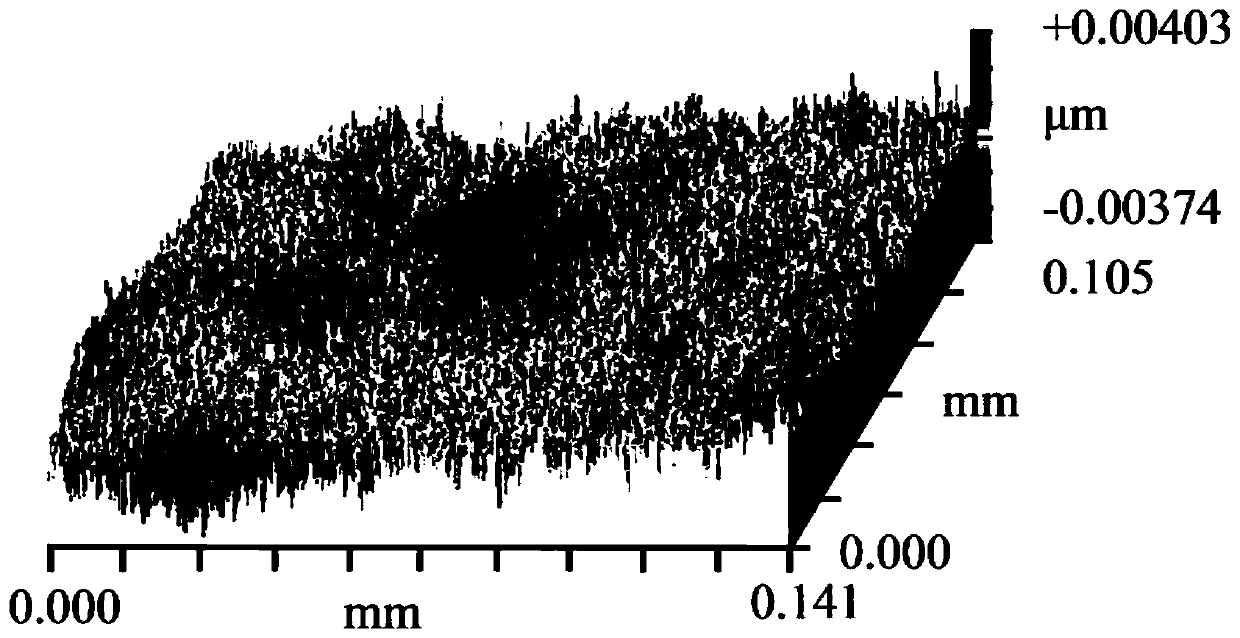

[0039] The main components and contents of the polishing liquid: the content of cerium oxide abrasive grains is 2%, the content of D-sorbitol is 0.5%, and the pH is adjusted to 5.4 with citric acid;

[0040] Process parameters: polishing pressure is 40.6kPa, polishing disc rotation speed is 80rpm;

[0041] The polished quartz glass surface roughness Ra value is 0.696nm, rms value is 0.874nm, PV value is 7.772nm (see figure 1 ).

Embodiment 2

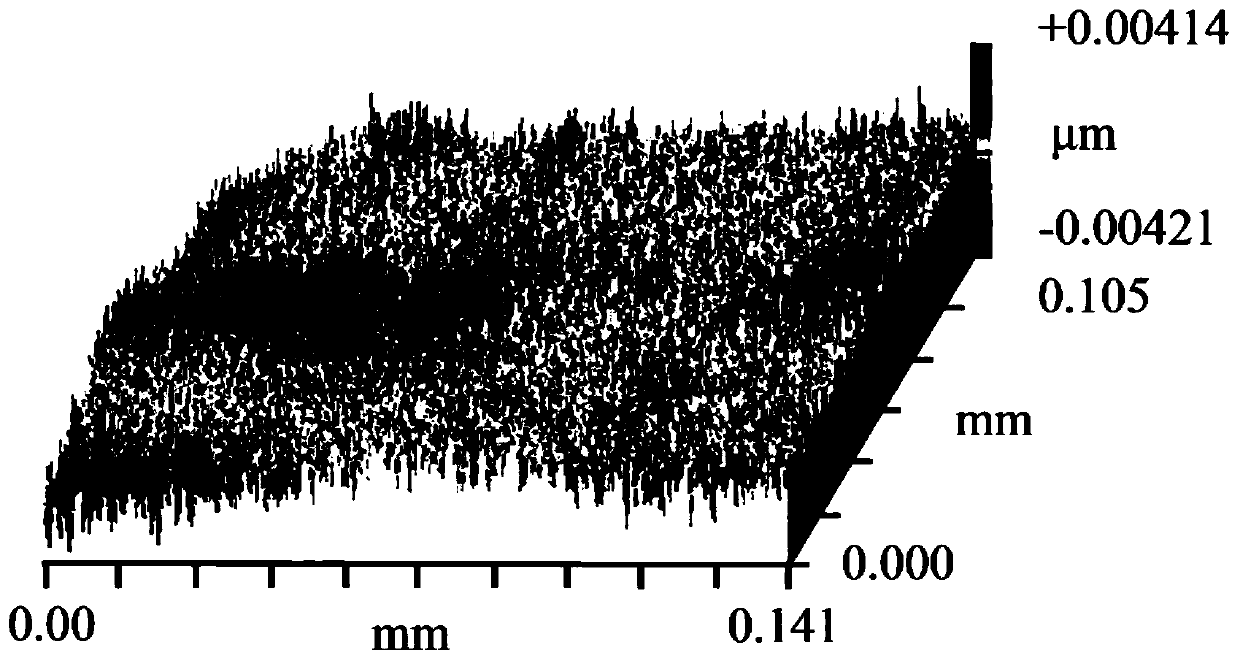

[0043] The main components and contents of the polishing liquid: the content of cerium oxide is 1%, the content of D-sorbitol is 0.5%, and the pH is adjusted to 4.3 by using citric acid;

[0044] Process parameters: polishing pressure is 44.2kPa, polishing disc rotation speed is 80rpm;

[0045] The polished quartz glass surface roughness Ra value is 0.742nm, rms value is 0.936nm, PV value is 8.355nm (see figure 2 ).

Embodiment 3

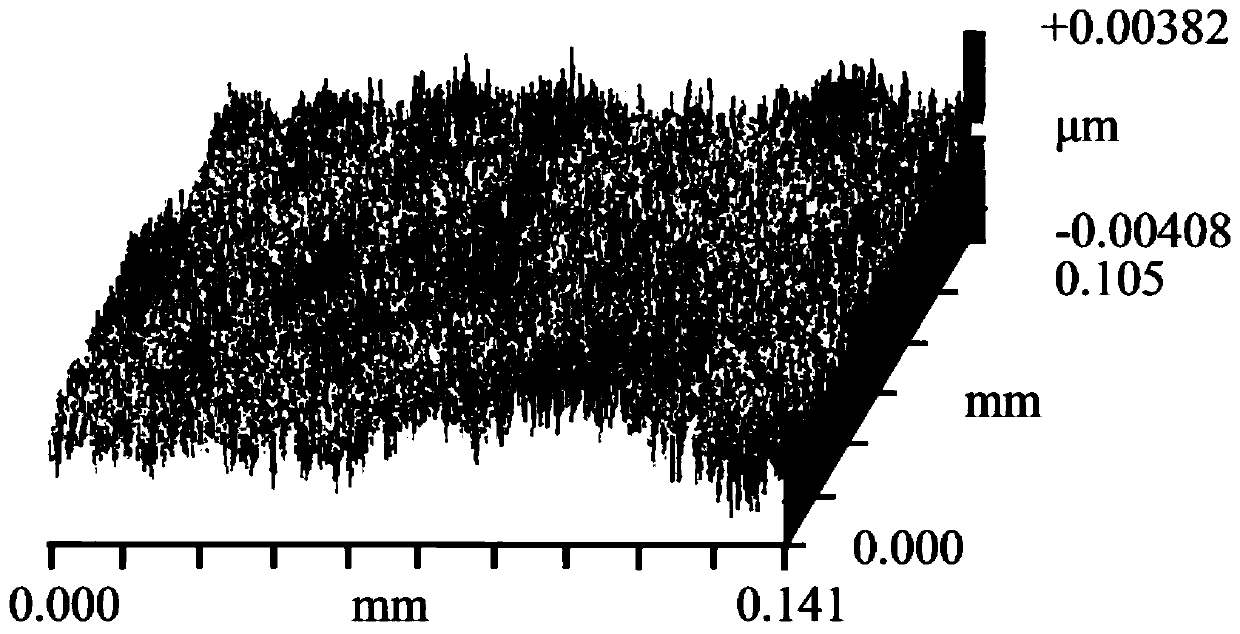

[0047] The main components and contents of the polishing liquid: the content of cerium oxide is 2%, the content of D-sorbitol is 1%, and the pH is adjusted to 5.3 by using citric acid;

[0048] Process parameters: polishing pressure is 38.0kPa, polishing disc rotation speed is 80rpm;

[0049] The polished quartz glass surface roughness Ra value is 0.659nm, rms value is 0.831nm, PV value is 7.900nm (see image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com