Carbon material, preparation method therefor and application of carbon material

A carbon material and raw material technology, which is applied in the field of carbon material and its preparation, can solve the problems of easy agglomeration, long catalyst life, high price, and reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0107]According to one embodiment of the present application, the preparation method of the fuel cell cathode catalyst comprises the following steps:

[0108] 1) Soak the mucormycetes in a solution containing iron ions and thiocyanate ions, and fully combine the inside and outside of the mucormycetes cells with the iron ions and thiocyanate ions by means of osmosis, adsorption or coordination bonding;

[0109] 2) After freezing the above-mentioned soaked mucormycetes, place them in a freeze dryer to complete freeze-drying, so that the mucormycetes cells retain the original morphological structure as much as possible;

[0110] 3) After the above-mentioned freeze-dried sample is subjected to high-temperature carbonization, the iron or iron oxide generated is removed with an acid solution, and the fuel cell cathode catalyst is obtained after washing, filtering and drying;

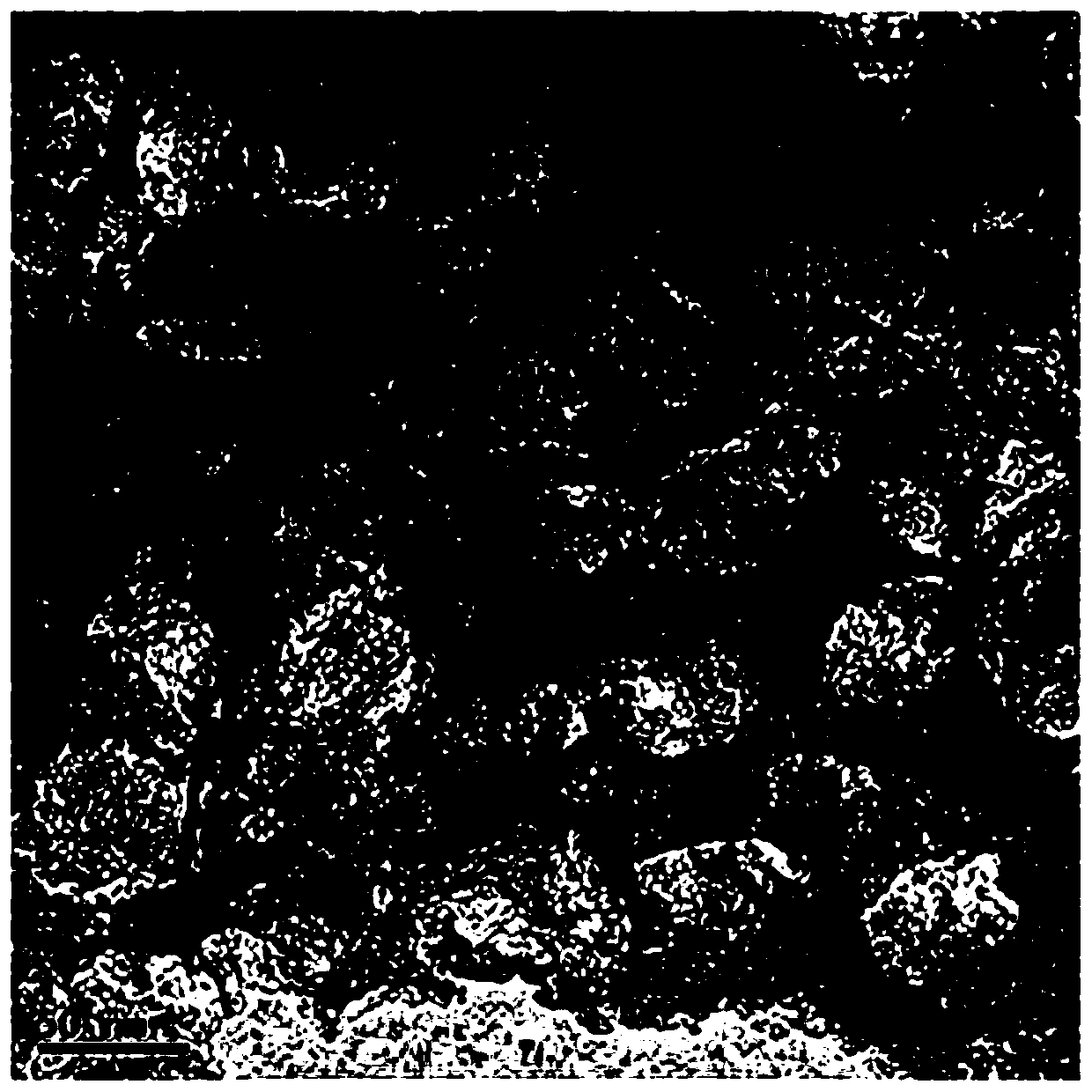

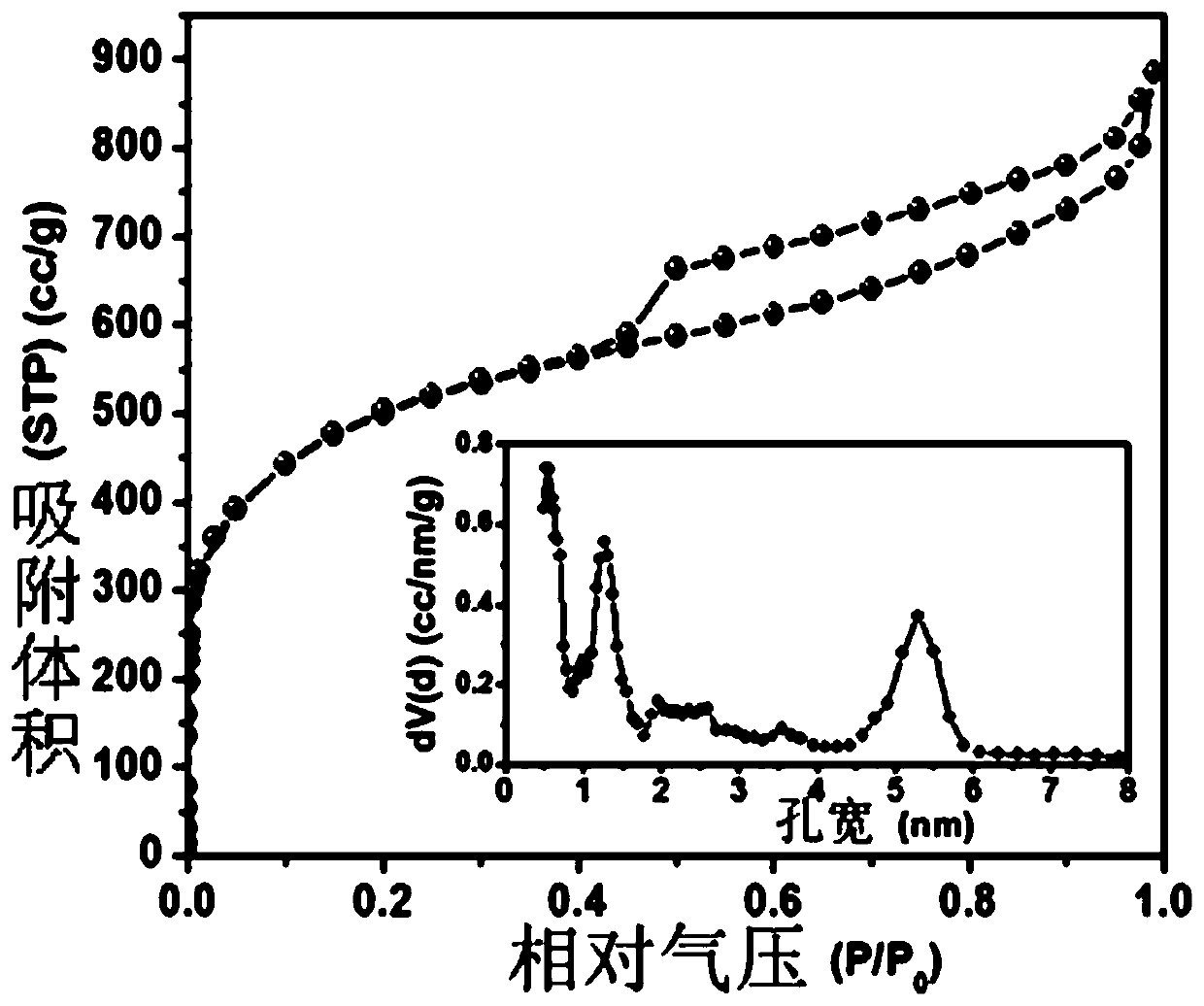

[0111] The fuel cell cathode catalyst is a hierarchically porous nano-carbon oxygen reduction catalyst co-d...

Embodiment 1

[0121] 1) Cultivate mucormycetes: Spray 6g of mucormycetes evenly on the surface of a total of 1.5kg of fresh tofu, place the tofu in an incubator with a temperature of 25°C and a humidity of 80%, and keep the training box ventilated , after 3 days of cultivation, the surface of the tofu is covered with white filamentous mucormycetes, and the mucormycetes are collected with tweezers;

[0122] 2) Soak 20g of mucormycetes in an aqueous solution containing iron ions and thiocyanate ions. The concentrations of iron ions and thiocyanate ions are 0.001mol / L and 0.003mol / L respectively. After soaking for 1 hour, the mucormycetes are basically The adsorption is saturated, take it out and drain it slightly, and put it in a refrigerator at minus 18°C to freeze it;

[0123] 3) placing the above-mentioned frozen mucormycosis in a freeze dryer to complete freeze-drying;

[0124] 4) Place the above freeze-dried sample in an atmosphere furnace for annealing and carbonization. The atmosphe...

Embodiment 2

[0130] The difference between this example and Example 1 is that the way of freezing in step 2) is: showering with liquid nitrogen, so that the object to be treated is quickly frozen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Hole width | aaaaa | aaaaa |

| Hole width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com