Centrifugal sprayed lining repairing mortar for pipeline and preparation method

A mortar and lining technology, which is applied in the field of pipeline centrifugal spraying lining repair mortar and preparation, can solve the problems of difficult to meet the requirements of centrifugal spraying construction, structural strength can not meet the repairing requirements, etc., to achieve good spraying operation, high Effects of Early Intensity, High Late Intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Embodiments of the present invention provide a preparation method of the above-mentioned pipeline centrifugal spray lining repair mortar, comprising the following steps:

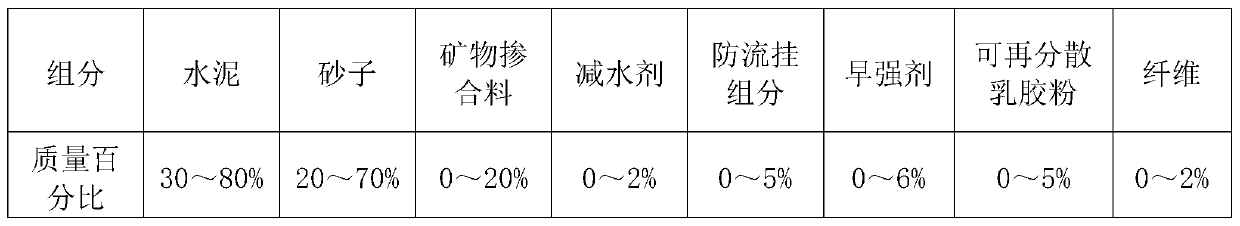

[0028] S1 Weigh 0-2 parts by weight of water reducer, 0-6 parts by weight of early strength agent, 0-5 parts by weight of anti-sag component and 0-5 parts by weight of redispersible latex powder, and premix them;

[0029] S2 weighs 30 to 80 parts by weight of cement, 20 to 70 parts by weight of sand, 0 to 20 parts by weight of mineral admixtures and 0 to 2 parts by weight of fiber, and adds them into the premixed mixture in step S1, and mixes them evenly to obtain mortar powder;

[0030] S3 Add water to the mortar powder according to the water-material ratio of 0.15-0.20 by weight, and stir evenly to obtain pipeline centrifugal spraying lining repair mortar.

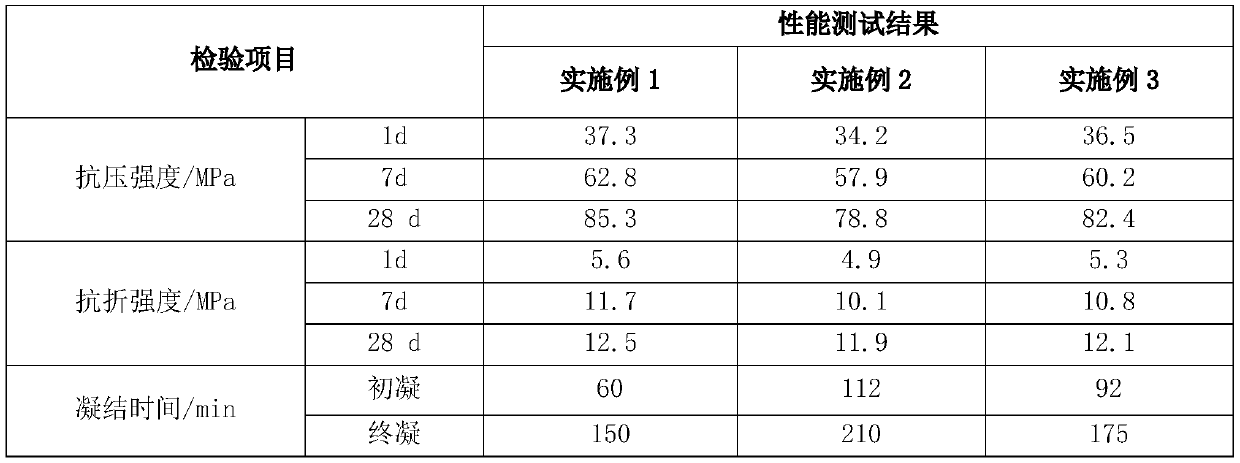

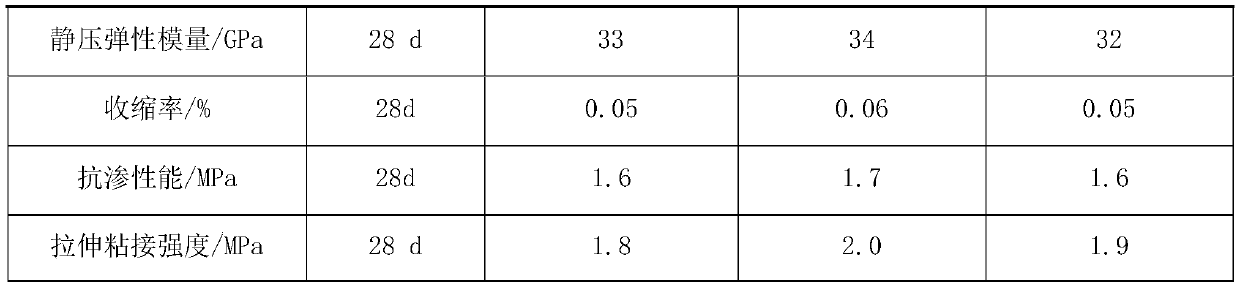

Embodiment 1

[0032] A pipeline centrifugal spray lining repair mortar, prepared from the following raw materials: ordinary portland cement 450g, 40-70 mesh quartz sand 430g, silica fume 30g, 2000 mesh limestone powder 40g, polycarboxylate superplasticizer 3g , Anti-sag component 5g, redispersible latex powder 20g, calcium formate 5g, sodium hexametaphosphate 6g, sodium sulfate 9g, polypropylene fiber 2g.

[0033] Preparation:

[0034] S1 Weigh 3g of polycarboxylate superplasticizer, 5g of calcium formate, 6g of sodium hexametaphosphate, 9g of sodium sulfate, 5g of anti-sag component and 20g of redispersible latex powder, add them into the container and premix them ;

[0035] S2 Weigh 450g of ordinary Portland cement, 430g of 40-70 mesh quartz sand, 30g of silica fume and 2g of polypropylene fiber, and add them to the premixed mixture in step S1, and mix to obtain mortar powder;

[0036] S3 Weigh 150g of water, add it to the mortar powder prepared in the step S2, and stir evenly to obtain...

Embodiment 2

[0038] A pipeline centrifugal spray lining repair mortar, prepared from the following raw materials, ordinary portland cement 460g, 20-40 mesh quartz sand 150g, 40-70 mesh quartz sand 280g, silica fume 30g, 4000 mesh limestone powder 30g, poly Carboxylic acid superplasticizer 3.5g, anti-sag component 7g, redispersible latex powder 15g, calcium formate 4g, gypsum 10g, sodium hexametaphosphate 8g, basalt fiber 2.5g.

[0039] Preparation:

[0040] S1 Weigh 3.5g of polycarboxylate superplasticizer, 4g of calcium formate, 10g of gypsum, 8g of sodium hexametaphosphate, 7g of anti-sag component and 15g of redispersible latex powder, add them to the container and premix them ;

[0041] S2 Weigh 460g of ordinary Portland cement, 150g of 20-40 mesh quartz sand, 280g of 40-70 mesh quartz sand, 30g of silica fume, 30g of 4000 mesh limestone powder and 2.5g of basalt fiber, and add them to the pre-prepared powder in step S1. In the mixture, mix well to obtain mortar powder;

[0042] S3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com