Method for extracting polysaccharide from overground parts of polygonatum cyrtonema

A technology of Rhizoma Polygonatum and its aerial parts, which is applied in the field of extraction technology of Rhizoma Polygonatum, can solve the problems of high production costs, achieve the effects of reducing supply prices, broadening supply channels, and increasing market supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

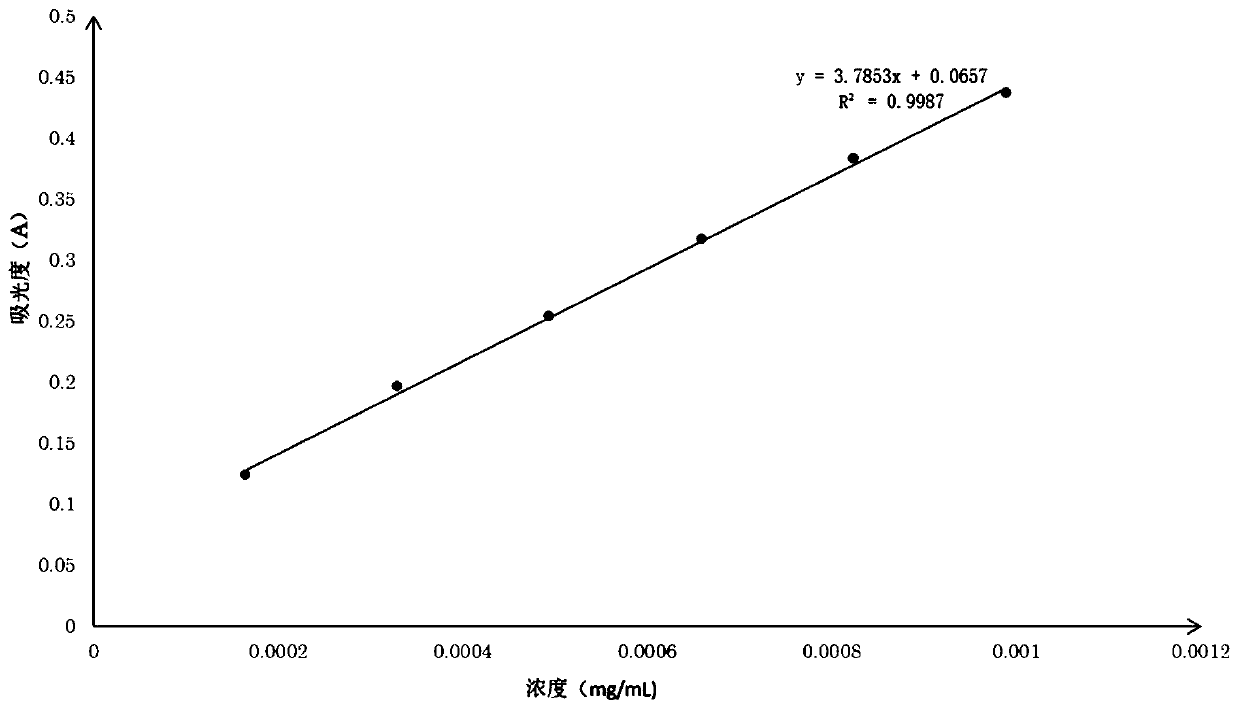

Image

Examples

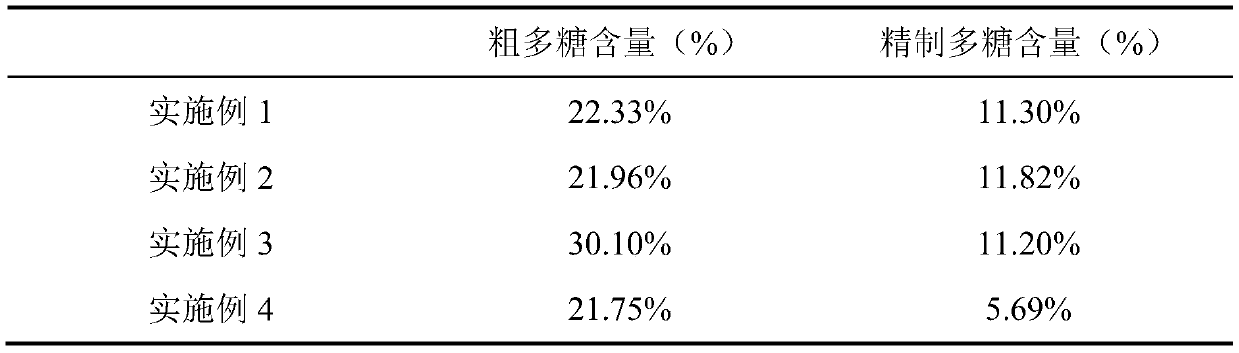

Embodiment 1

[0030] This embodiment is used to extract the polysaccharide of the aerial part of Polygonatum multiflora, and the specific process is as follows:

[0031] (1) Drying: collect the aerial part of Polygonatum multiflora, and dry it in an oven at 55°C until the water content does not exceed 10%.

[0032] (2) Pulverization: take the dried Rhizoma Polygonatum raw material, and pulverize it through a No. 4 sieve.

[0033] (3) Degreasing and impurity removal: Add 10 times the amount of petroleum ether (boiling range 60-90°C) to the Polygonatum polyphagoides powder, shake well, reflux in a water bath at 75°C for 2 hours, suction filter to recover petroleum ether, and evaporate the filter cake at the same time residual petroleum ether. After adding 10 times the amount of 95% ethanol solution to the filter cake to reflux for extraction for 1.5 h, the filter residue was collected by suction filtration and dried in an oven at 55°C.

[0034] (4) Extraction: Mix the filter residue of the ...

Embodiment 2

[0039] This embodiment is used to extract the polysaccharide of the aerial part of Polygonatum multiflora, and the specific process is as follows:

[0040] (1) Drying: collect the aerial part of Polygonatum multiflora, and dry it in an oven at 55°C until the water content does not exceed 10%.

[0041] (2) Pulverization: take the dried Rhizoma Polygonatum raw material, and pulverize it through a No. 4 sieve.

[0042] (3) Degreasing and impurity removal: Add 10 times the amount of petroleum ether (boiling range 60-90°C) to the Polygonatum polyphagoides powder, shake well, reflux in a water bath at 75°C for 2 hours, suction filter to recover petroleum ether, and evaporate the filter cake at the same time residual petroleum ether. After adding 10 times the amount of 95% ethanol solution to the filter cake to reflux for extraction for 1.5 h, the filter residue was collected by suction filtration and dried in an oven at 55°C.

[0043] (4) Extraction: Mix the filter residue of the ...

Embodiment 3

[0047] This embodiment is used to extract the polysaccharide of the aerial part of Polygonatum multiflora, and the specific process is as follows:

[0048] (1) Drying: collect the aerial part of Polygonatum multiflora, and dry it in an oven at 55°C until the water content does not exceed 10%.

[0049] (2) Pulverization: take the dried Rhizoma Polygonatum raw material, and pulverize it through a No. 4 sieve.

[0050] (3) Extraction: mix the above-ground part of Rhizoma Polygonatum with 15 times the amount of distilled water evenly, reflux extraction twice, each time for 2 hours, suction filter and collect the filtrate.

[0051] (4) Concentration and precipitation: the obtained filtrate is concentrated under reduced pressure at 60°C to 1 / 6 volume of the initial filtrate, and 95% ethanol is slowly added to the suction filtrate with constant stirring until the final concentration of ethanol is 80%, and placed at 4°C Centrifuge after 12 hours.

[0052] (5) Decolorization: Discard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com