Method for preparing nanocellulose by taking folium artemisiae argyi residues after essential oil extraction as raw material

A nanocellulose and cellulose technology, which is applied in the post-processing of cellulose pulp, cellulose treatment with microorganisms/enzymes, and fiber raw material treatment, etc., can solve the problems of shortening the duration of heat release, burning rate, and low heat release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

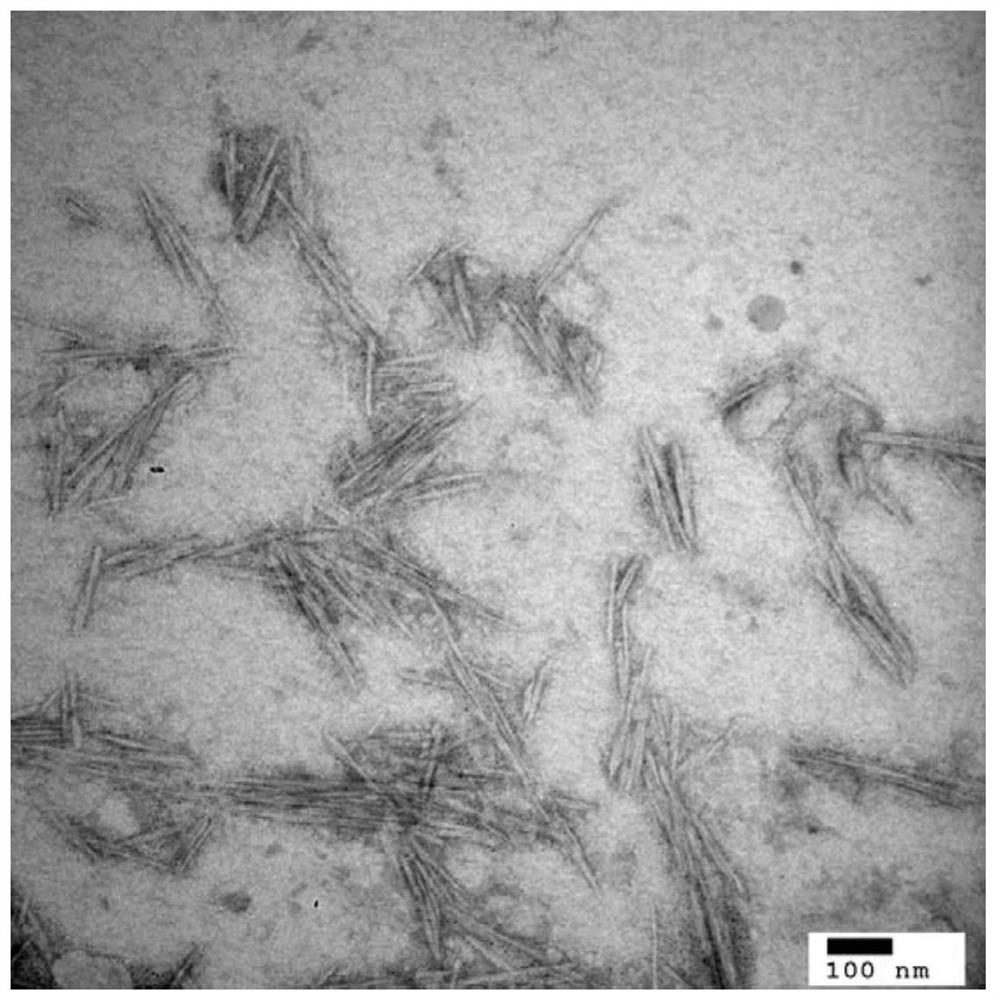

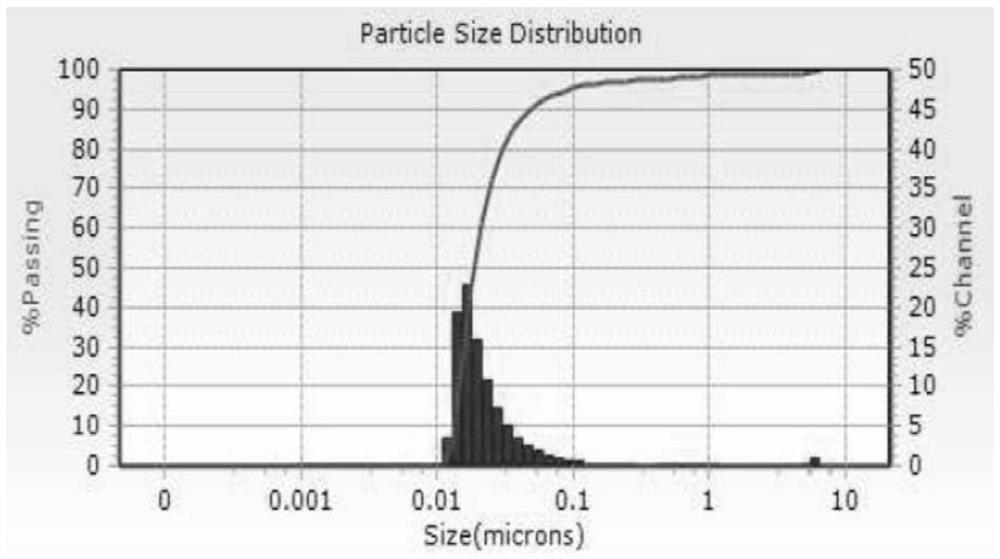

Image

Examples

Embodiment 1

[0074] (1) Take 50 g of Artemisia argyi leaves residue (solid content is 10wt%) after extracting essential oil from a certain factory, add papain, and the amount of papain added is 500 U per kilogram of Artemisia argyi leaf residue; Enzymolysis at a stirring speed of 30 rpm and 35°C 90 minutes; filter, and dry the solid in an oven at 105°C for 30 minutes;

[0075] (2) Put the dried solid into a Soxhlet extractor equipped with a benzene-ethanol mixture (2:1 in volume ratio), heat and extract in a water bath for 6 hours, and the temperature of the water bath is 80±5°C to ensure that the solvent circulates for 4 hours per hour. times; filter, the extracted residue is naturally air-dried at room temperature to obtain a dry material;

[0076] (3) Put the dry material in a sodium hydroxide solution with a mass concentration of 10%, with a solid-to-liquid ratio of 1:5g / mL; ultrasonically remove hemicellulose at 50°C for 2.5h; filter, and dry at 105°C until the water content is less t...

Embodiment 2

[0081] (1) Get 30g (water content is 90wt%) of Folium Artemisiae Argyi residue after laboratory water steam distillation extracts essential oil, add papain, the addition of papain is 800U per kilogram of Folium Artemisiae Argyi residue; Enzymolysis under high temperature for 60 minutes; filter, and dry the solid in an oven at 105°C for 40 minutes;

[0082] (2) Put the dried solid into a Soxhlet extractor equipped with ether, heat and extract in a water bath for 5 hours, the temperature of the water bath is 85±5°C, and ensure that the solvent is circulated 6 times per hour; Air-dried to obtain dry material;

[0083] (3) Put the dry material in a sodium hydroxide solution with a mass concentration of 10%, and the solid-to-liquid ratio is 1:5g / mL; ultrasonically remove hemicellulose at 40°C for 3h; filter, and dry at 105°C until the water content is less than 10wt %, to obtain crude cellulose;

[0084] (4) then carry out peracetic acid bleaching to the cellulose crude product t...

Embodiment 3

[0088] (1) Get 50 g of Artemisia argyi leaves residue (solid content is 8.3wt%) after extracting essential oil by steam distillation, add papain, and the addition of papain is 500 U per kilogram of Artemisia argyi leaf residue; At stirring speed, it is 30 rev / min, 55 DEG C Enzymolysis for 40 minutes; filter, and dry the solid;

[0089] (2) Put the dried solid into a Soxhlet extractor filled with a toluene-ethanol mixture (volume ratio 2:1), heat and extract in a water bath for 6 hours, and the temperature of the water bath is 90±5°C to ensure solvent circulation per hour 6 times; filter, and air-dry the residue after extraction at room temperature to obtain a dry material;

[0090] (3) Put the dry material in a sodium hydroxide solution with a mass concentration of 10%, and the solid-to-liquid ratio is 1:5g / mL; ultrasonically at 60°C for 2 hours to remove hemicellulose; filter, and dry at 105°C until the moisture is less than 10wt %, to obtain crude cellulose;

[0091] (4) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com