Multifunctional self-healing hydrogel and its preparation method and application in the detection of biogenic amines

A self-healing and hydrogel technology, which is applied in the direction of analyzing materials through chemical reactions and observing the impact on chemical indicators, etc., can solve problems such as poor mechanical properties, single function, and long self-healing time. problem, to achieve the effect of short time, expanding application range, and mild gelation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

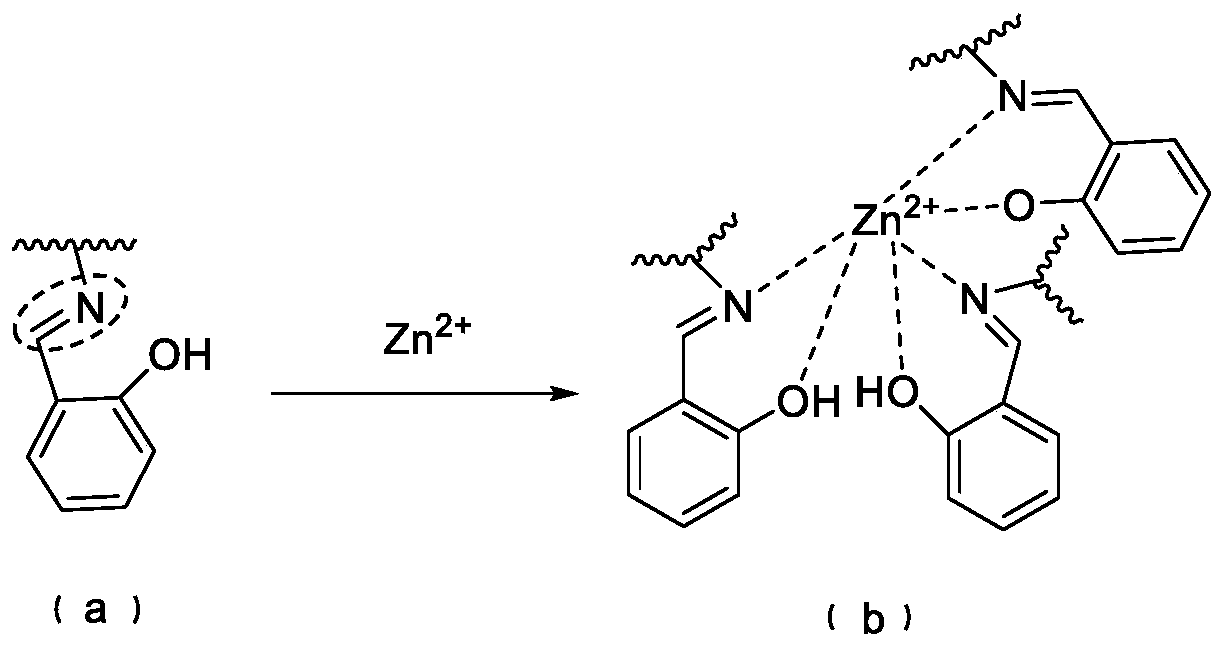

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a multifunctional self-repairing hydrogel, comprising the steps of:

[0048] (1) Preparation of 5-chloromethyl-2-hydroxy-benzaldehyde (CHBA): Add 50mmol of polyoxymethylene and 100mmol of salicylaldehyde to the flask, place in ice bath, slowly add 84mL of concentrated hydrochloric acid (12mol / L) dropwise, Stir at room temperature for 48 h, wash with deionized water to pH = 7 after the reaction, recrystallize in n-hexane, and dry.

[0049] (2) Preparation of polyethylene glycol dimesylate (DE-PEG): Add 10 mmol polyethylene glycol 4000 and 40 mmol triethylamine to the dichloromethane solution in an ice bath, and slowly add 40 mmol methanesulfonate dropwise Acyl chloride, stirred at room temperature for 48h, removed dichloromethane after the reaction, washed with deionized water, precipitated with ether, and dried.

[0050] (3) Preparation of imidazole-terminated polyethylene glycol (Im-PEG): 10mmol polyethylene glycol dimesylate (DE-PEG), 40mmol im...

Embodiment 2

[0061] A method for preparing a multifunctional self-repairing hydrogel, comprising the steps of:

[0062] (1) Preparation of 5-chloromethyl-2-hydroxy-benzaldehyde (CHBA): Add 50mmol of polyoxymethylene and 100mmol of salicylaldehyde to the flask, place in ice bath, slowly add 42mL of concentrated hydrochloric acid (12mol / L) dropwise, Stir at room temperature for 24 h, wash with deionized water to pH=6 after the reaction, recrystallize in n-hexane, and dry.

[0063] (2) Preparation of polyethylene glycol dimesylate (DE-PEG): under ice bath conditions, 10 mmol polyethylene glycol 800 and 20 mmol triethylamine were added to the acetone solution, and 20 mmol methanesulfonyl chloride was slowly added dropwise, Stir at room temperature for 60 h, remove acetone after the reaction, wash with deionized water, precipitate with ether, and dry.

[0064] (3) Preparation of imidazole-terminated polyethylene glycol (Im-PEG): 10mmol polyethylene glycol dimesylate (DE-PEG), 20mmol imidazole ...

Embodiment 3

[0069] A method for preparing a multifunctional self-repairing hydrogel, comprising the steps of:

[0070](1) Preparation of 5-chloromethyl-2-hydroxy-benzaldehyde (CHBA): Add 50mmol of polyoxymethylene and 150mmol of salicylaldehyde to the flask, place in ice bath, slowly add 70mL of concentrated hydrochloric acid (12mol / L) dropwise, Stir at room temperature for 36 h, wash with deionized water to pH = 7 after the reaction, recrystallize in n-hexane, and dry.

[0071] (2) Preparation of polyethylene glycol dimesylate (DE-PEG): under ice bath conditions, add 10 mmol polyethylene glycol 10000 and 100 mmol triethylamine to the dimethyl sulfoxide solution, slowly drop 100 mmol Methanesulfonyl chloride was stirred at room temperature for 56 hours. After the reaction, dimethyl sulfoxide was removed, washed with deionized water, precipitated with ether, and dried.

[0072] (3) Preparation of imidazole-capped polyethylene glycol (Im-PEG): 2-butanone added to 10mmol polyethylene glycol...

PUM

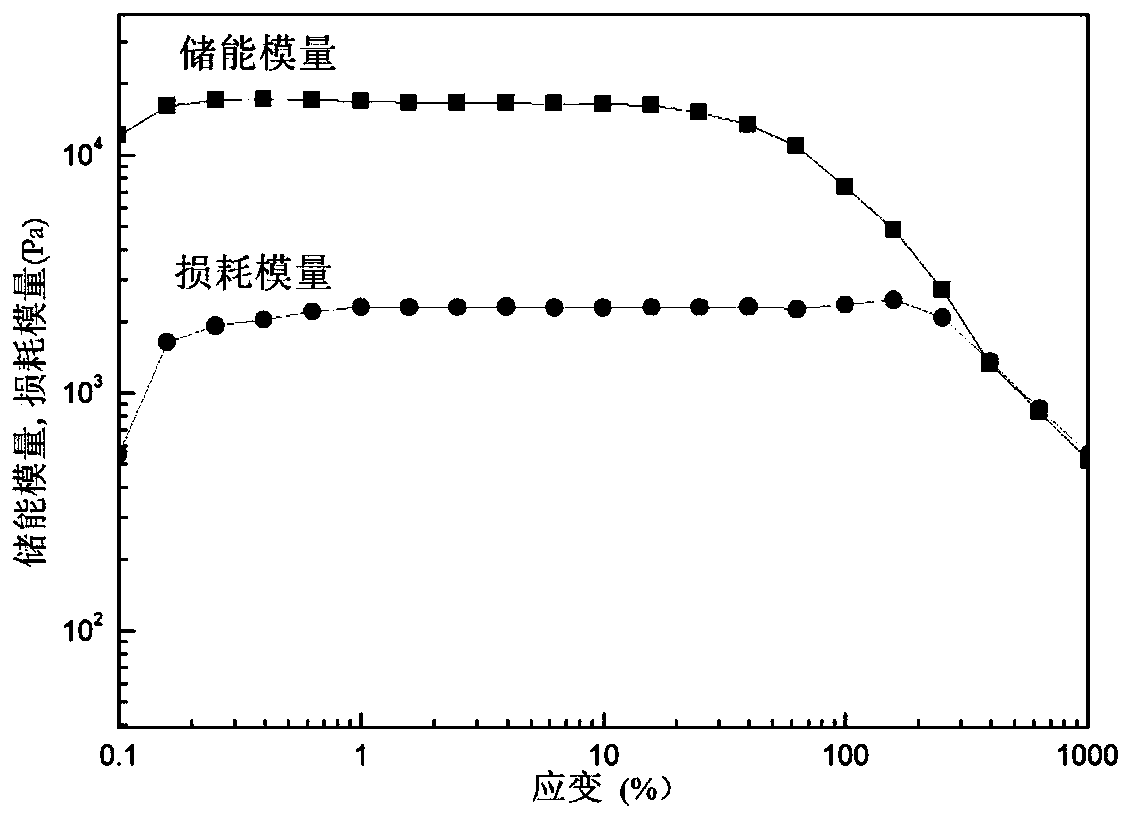

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com