A nanoparticle compatibilizer based on carbon quantum dots and its preparation method and application

A technology of nanoparticles and carbon quantum dots, which is applied in the field of nanoparticle compatibilizers based on carbon quantum dots and its preparation, can solve the problems of reduced compatibility efficiency, achieve improved compatibility, high yield, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

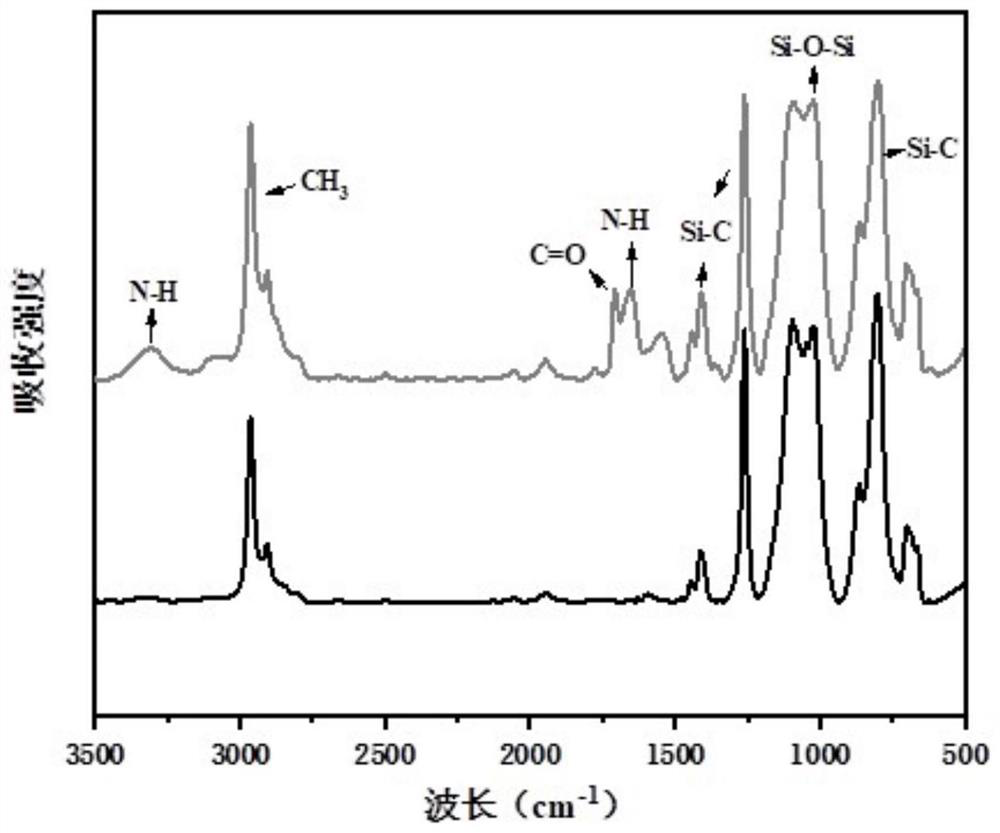

[0040] This embodiment provides a preparation of amino carbon quantum dots, specifically as follows:

[0041] Weigh 0.5g of citric acid powder and 10ml of amino silicone oil with a molecular weight of 300 into a 100ml polytetrafluoroethylene lining, and put the lining in a stainless steel reaction kettle after passing through nitrogen gas, put it in an oven and react at 150°C for 6h . After the reactor is cooled to room temperature, a light brown liquid is obtained, which is the amino carbon quantum dot I (NH 2 -CDs-1).

Embodiment 2

[0043] The present embodiment provides a kind of preparation method of copolymer, and the steps are as follows:

[0044] With the NH that embodiment 1 makes 2 -CDs-1 is a compatibilizer.

[0045] 3g NH 2 - CDs-1 were dissolved in 20 ml THF, 30 g methyl vinyl silicone rubber (MVQ) was dissolved in 300 ml THF.

[0046] After mixing the above solutions evenly, remove the solvent and dry to obtain MVQ / NH 2 - CDs-1 composite material;

[0047] The above composite material and 70g TPU were melted and kneaded in a Haake internal mixer under the conditions of 180°C, 5min, and a speed of 60rmp, and the final composition was MVQ / TPU / NH2 -The blend system of CDs-1(30:70:3).

Embodiment 3

[0052] This embodiment provides a method for preparing amino carbon quantum dots, the steps are as follows:

[0053] Weigh 0.5g of citric acid powder and 10ml of amino silicone oil with a molecular weight of 2000 into a 100ml polytetrafluoroethylene lining, and put the lining in a stainless steel reaction kettle after passing through nitrogen gas, put it in an oven and react at 180°C for 6h . After the reactor is cooled to room temperature, a light brown liquid is obtained, which is the amino carbon quantum dot II (NH 2 -CDs-2). The size is 7nm. Such as figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com