Steel structure and insulation structure integrated fixed mold shear wall and construction method

A construction method and technology of steel structure, applied in the direction of thermal insulation, building thermal insulation materials, walls, etc., can solve the problems of fire hazard waterproof, anti-termite, thermal insulation and waterproof performance damage, external wall thermal insulation system and structure cannot be integrated, etc. The effect of reducing oxidation point strength defects, good fire resistance and corrosion resistance stability, and efficient and rapid construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

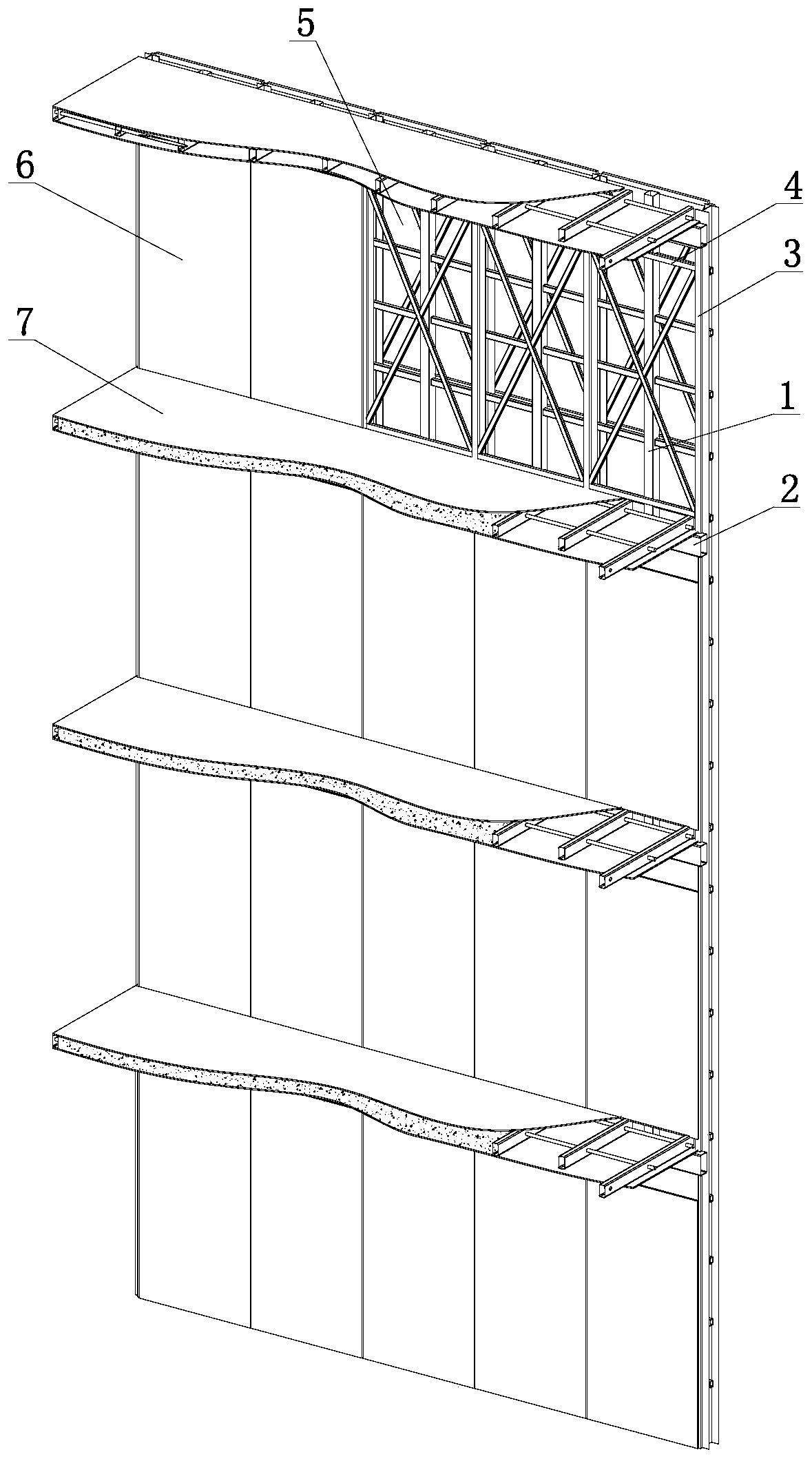

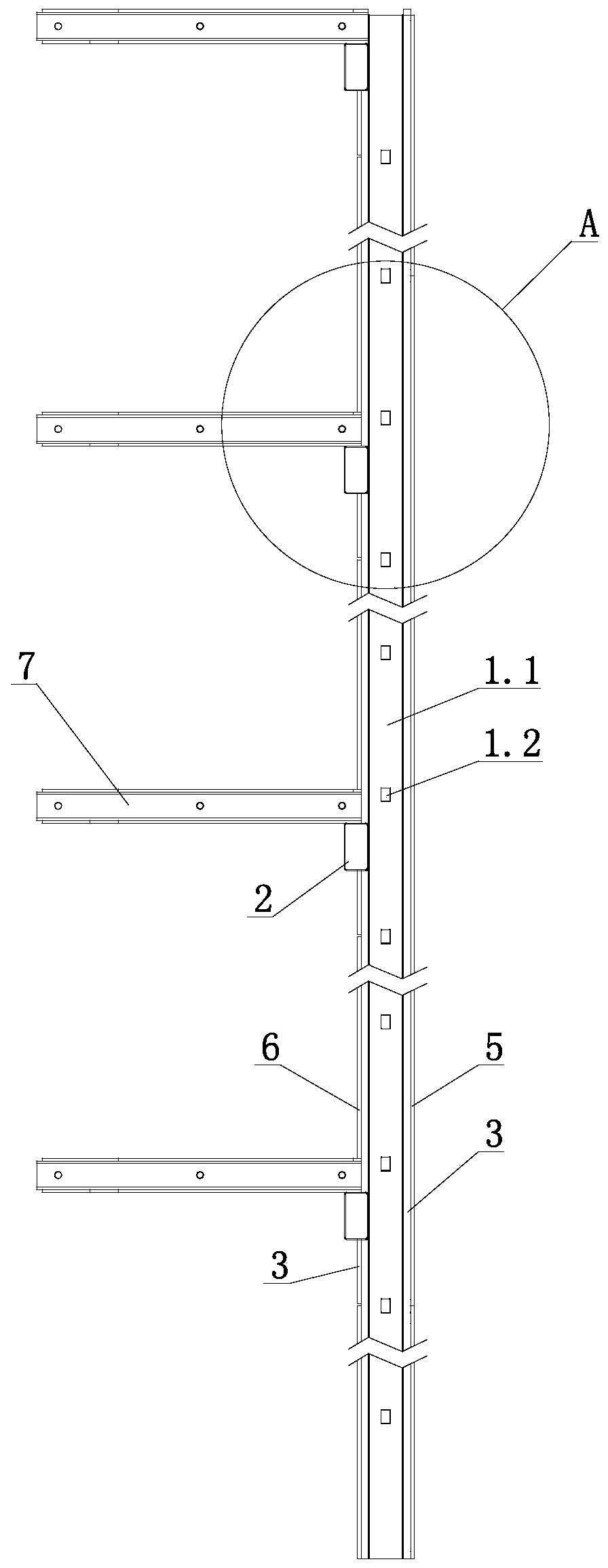

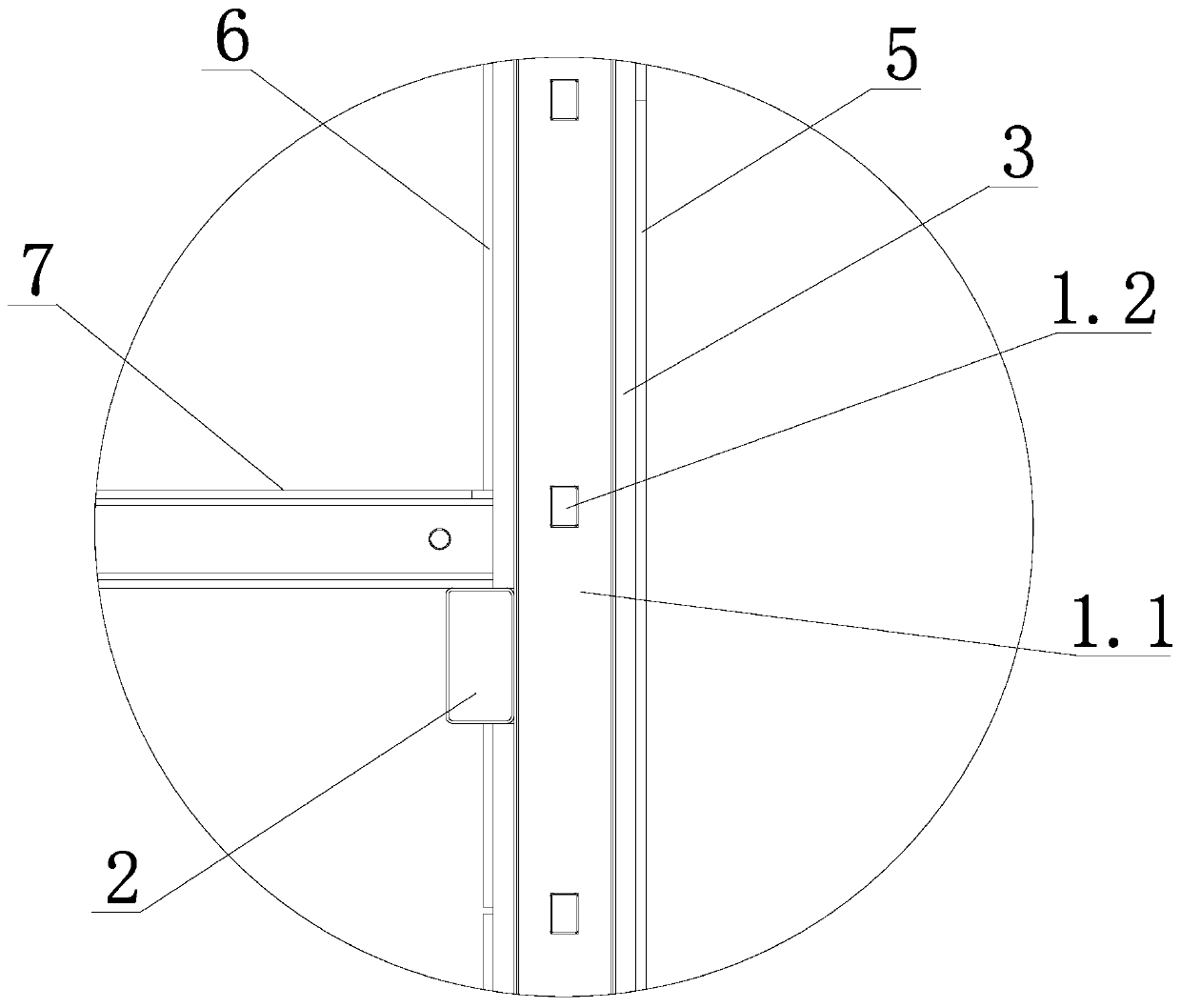

[0078] This embodiment is a light steel three-story low-rise new residential building with a floor height of 3000mm and a total height of 9500mm. The thickness of the outer wall is 252mm. The components are as follows:

[0079] steel structure

[0080] 1. Ring beam structure:

[0081] Geosphere beam: specification 100x50x5, material: Q235b anti-corrosion treatment is epoxy coal tar pitch, three oil and two cloth.

[0082] Interlayer ring beam and upper ring beam: Specification 120x60x2.5, material Q235b hot-dip galvanized rectangular steel pipe.

[0083] 2. Enclosure shear force and internal shear wall structure:

[0084] Vertical column: specification 80x80x2.5x9400, material Q235b hot-dip galvanized rectangular steel

[0085] Cross brace: specification 60x40x2.0, material Q235b hot-dip galvanized rectangular steel

[0086] Diagonal brace: specification 40x40x1.5, material Q235b hot-dip galvanized rectangular steel

[0087] 3. Processing and assembly

[0088] Perforate ...

Embodiment 2

[0122] This embodiment is a multi-storey residential building with a mixed structure of ordinary steel and light steel. The total height is 7 floors, the floor height is 3 meters, the total height is 21 meters (2100), the thickness of the outer wall is 340mm, and the area of 60x12 buildings is 5040m 2

[0123] 1. Steel structure

[0124] Ground circle beam 180×100×8 Q235 anti-corrosion channel steel

[0125] Interlayer ring beam 160×60×8 Q235 channel steel

[0126] 2. Enclosure shear wall and inner scissor wall structure

[0127] Vertical column 200×120×8×10000 Q325 H-shaped steel

[0128] Cross brace 100×50×2.0 Q325 hot-dip galvanized rectangular steel

[0129] Diagonal brace 40×60×2.0 Q325 hot-dip galvanized rectangular steel

[0130] 3. Drill 42×62 holes on the H steel of the vertical column according to the designed tie rod spacing, and drill DN120 slurry holes on the web plate with a hole distance of 800mm, and drill holes for fixing the diagonal brace on the H ste...

Embodiment 3

[0162] Present embodiment is the shear wall of the high-rise building of concrete frame-shear structure, and the distance between concrete column and opening is 4000 * 8000, and its construction method is as follows:

[0163] The steel structure of the shear wall is a light steel structure, which can be cut according to the size of the column distance from the opening. In this embodiment, the column distance from the hole is 4000×8000, that is, the height is 4000 (4 meters), the length is 8000 (8 meters), and the wall thickness is 250mm.

[0164] 1. Steel structure:

[0165] (1) Vertical column 50×100×20×2.5×7980 hot-dip C-shaped steel Q235

[0166] (2) Cross brace 60×60×45×2.0 hot-dip galvanized Z-shaped steel Q235

[0167] (3) Diagonal brace 30×50×1.5 hot-dip rectangular steel Q235b

[0168] 2. Processing and assembly

[0169] According to the design requirements, the distance between the horizontal braces is 1000, that is, slots (holes) are sequentially made on the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com