A fabrication method of pixel-level on-chip spectroscopy chip based on metasurface structure

A metasurface, pixel-level technology, applied in the field of micro-nano photonics device preparation, can solve the problems of narrow working band range, complex preparation process, and the inability of image sensors to correspond one-to-one pixels. Information collection, flexible design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

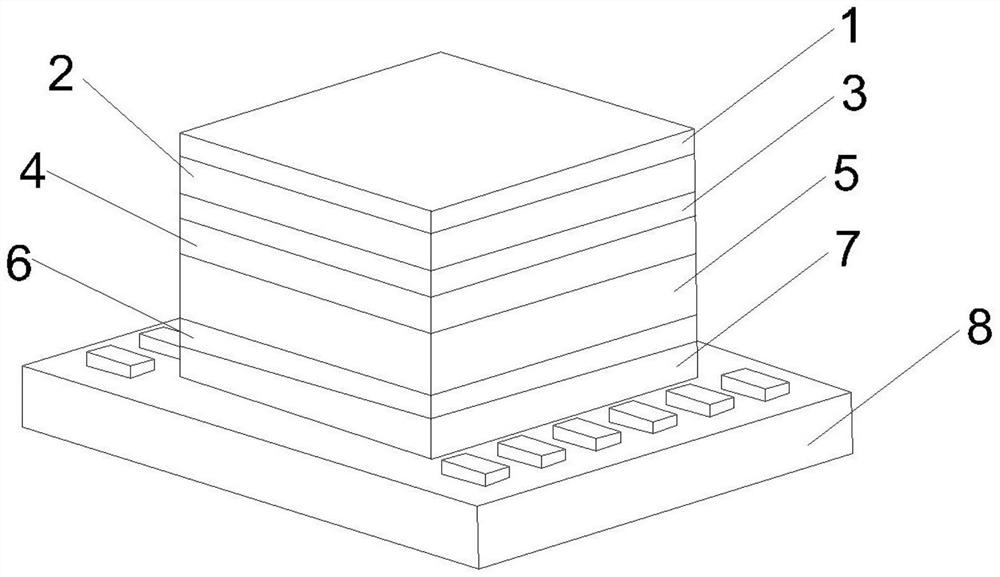

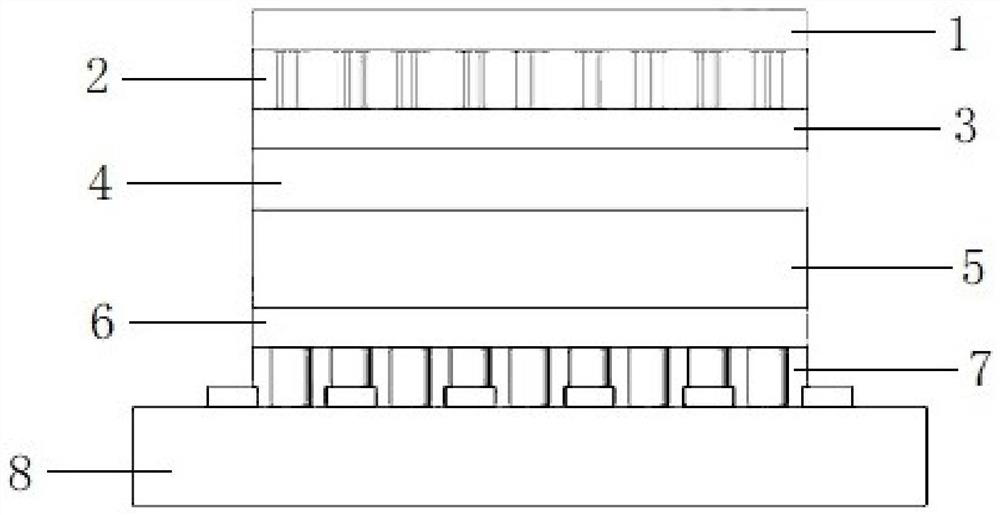

[0031] Such as Figure 1-2 As shown, a method for preparing a pixel-level on-chip spectrum chip process based on a metasurface structure is characterized in that it comprises the following steps:

[0032] S1: In the cap layer InP of the InP / InGaAs / InP material, Zn diffusion process, ultraviolet lithography process and electron beam evaporation process are used to prepare the pixel, P-type metal electrode and overlay mark of the detector;

[0033] S2: N-type metal electrodes are prepared in the cap layer InP of InP / InGaAs / InP material by wet etching process and electron beam evaporation process;

[0034] S3: Thinning and polishing process is carried out on the substrate InP of InP / InGaAs / InP material, and a dielectric layer is passivated by plasma chemically enhanced vapor deposition on the polished InP surface, and a dielectric layer is deposited on the surface of the dielectric layer by low-pressure chemical deposition growing monocrystalline silicon;

[0035] S4: Prepare a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com