Method for epitaxial growth of gallium nitride (GaN) thin film on Si substrate

An epitaxial growth and substrate technology, applied in coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of difficult realization and complex growth process, improve the quality of epitaxy, simplify the growth process, and be easy to realize Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

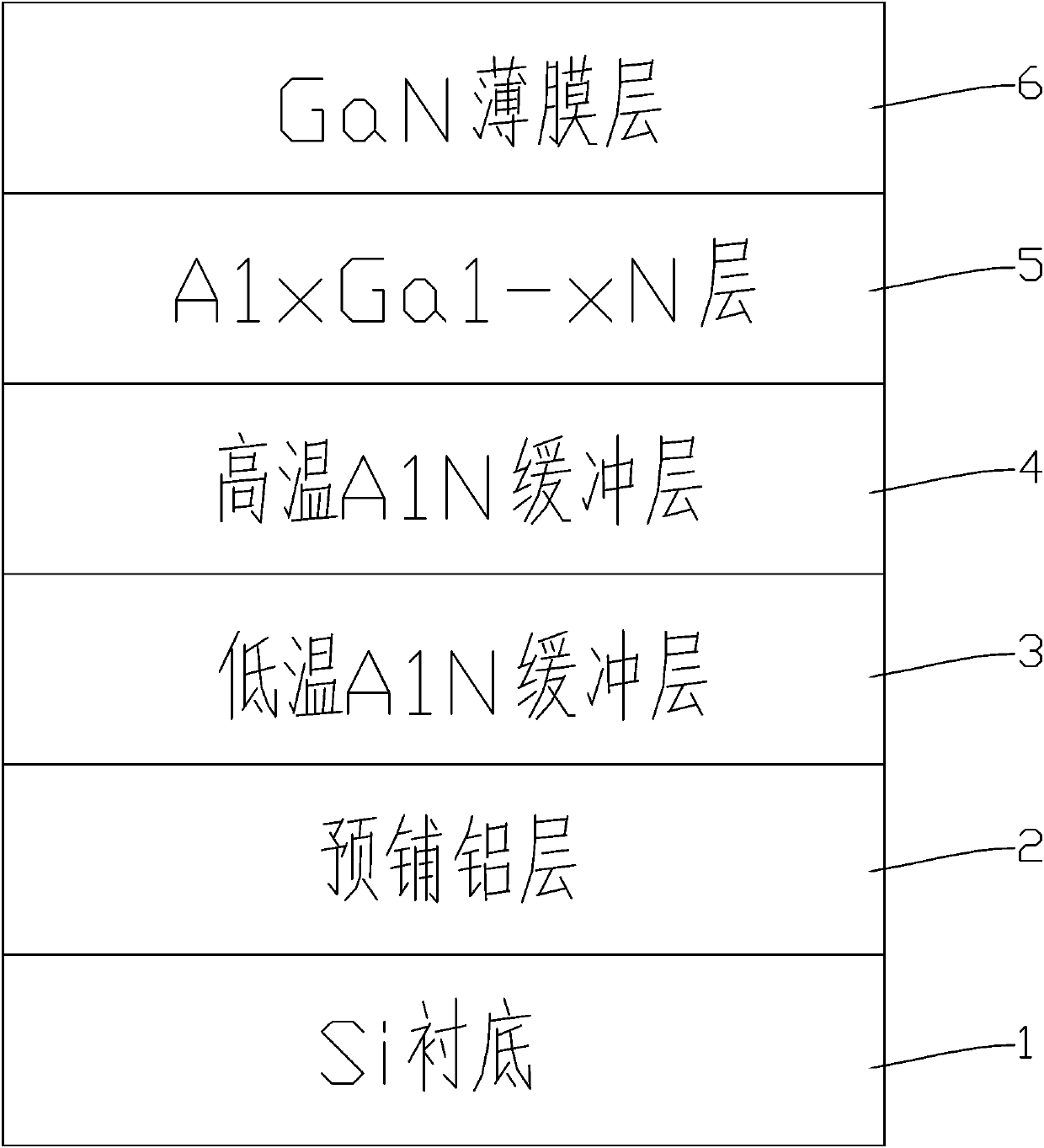

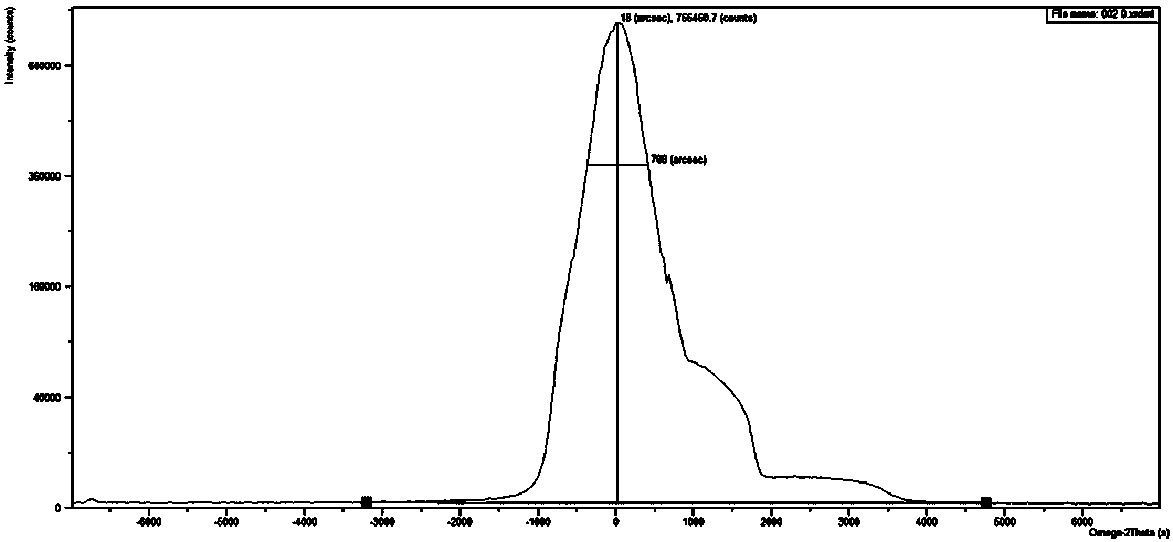

[0028] refer to Figure 1-4 As shown, the method for epitaxially growing a GaN thin film on a Si substrate of the present invention adopts an MOCVD system for epitaxial growth. Its epitaxial structure is Si substrate 1, pre-coated aluminum layer 2, low-temperature AlN buffer layer 3, high-temperature AlN buffer layer 4, Al x Ga 1-xN layer 5 and GaN thin film layer 6. Among them: the low-temperature AlN buffer layer 3 is a low-temperature AlN three-dimensional nucleation layer, the high-temperature AlN buffer layer 4 is a high-temperature AlN two-dimensional nucleation layer, the AlxGa1-xN layer 5 is an AlxGa1-xN stress release layer, and the GaN film layer 6 is the final growth layer . As mentioned above, AlN is aluminum nitride, AlxGa1-xN is aluminum gallium nitride, and GaN is gallium nitride. During the growth process, TMGa (trimethylgallium) and TMAl (trimethylaluminum) are used as Ga sources respectively (Ga (gallium) atoms cleaved from trimethylgallium at high temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com