Photopolymerization gel for self-feedback of hardness distribution via color and preparation method and application thereof

A technology of hardness distribution and self-feedback, which is applied in the direction of analyzing materials through chemical reactions and observing the influence of chemical indicators. Issues such as regulation or detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

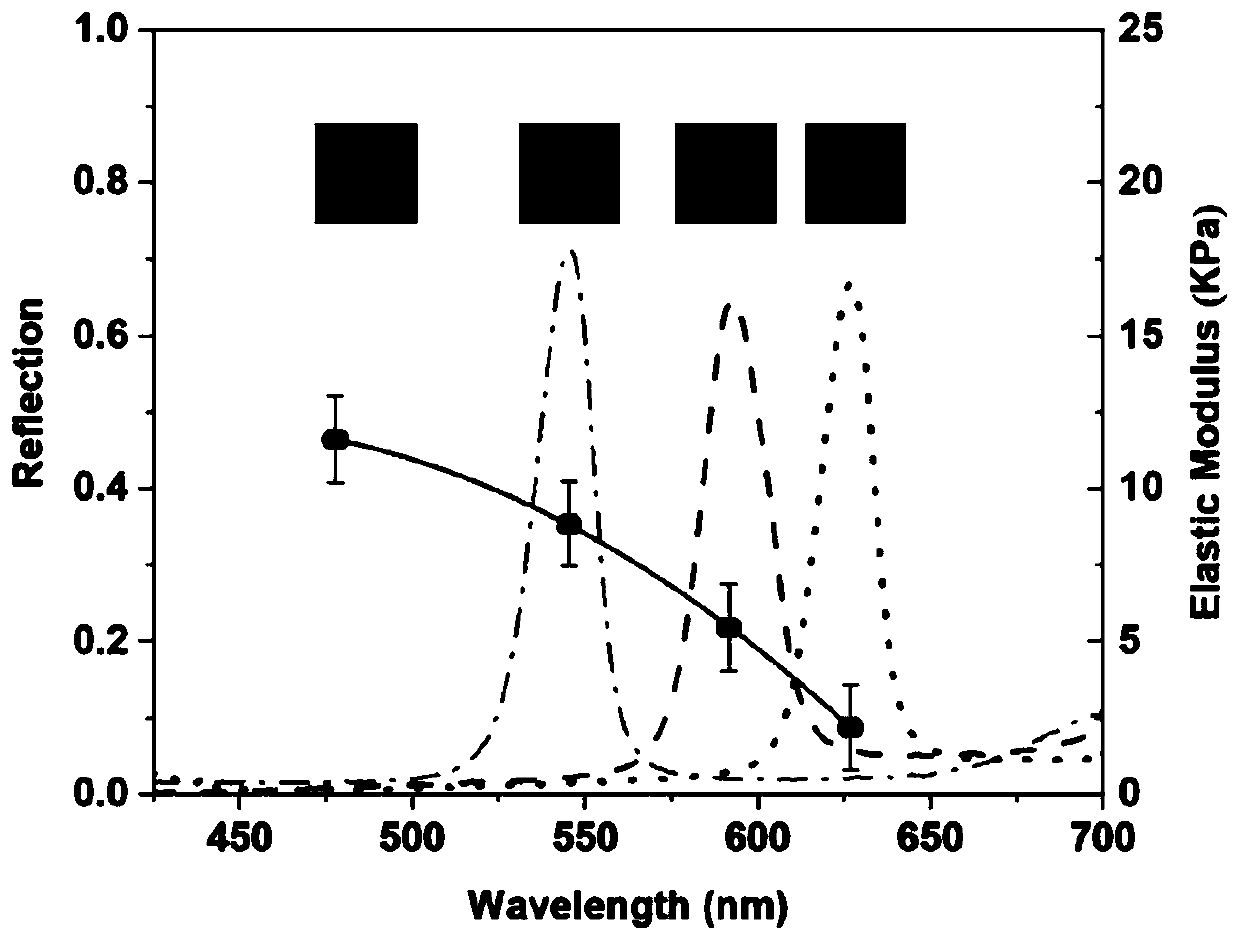

[0034] 1) Add acrylamide (7.00mg), Bis / PEGDA700 (0.08mg) and photoinitiator 2959 (0.08mg) to water-dispersed silica nanoparticles (90μL, Ф152nm, 30vol%); obtain a prepolymer solution;

[0035] 2) Ultrasonic treatment of the prepolymer solution obtained in 1) for 5 minutes;

[0036] 3) On the basis of 2), the pre-polymerization solution is evenly penetrated into the space between the two parallel glasses separated by capillary force, the gap thickness is 25 μm, and then exposed to the ultraviolet light of λ=365nm for 10s, 30s, 45s, 60s, 120s to photopolymerize the monomer; thus obtain hydrogel films of different colors and hardness;

[0037] 4) In order to increase cell affinity, gelatin was grafted onto the surface of the hydrogel membrane of 3). The hydrogel membranes were then sterilized in 75% ethanol in Petri dishes, in sterile PBS for at least 3 hours and in cell culture medium for 1 hour; the cell culture medium was removed and fresh cell culture medium was injected.

[...

Embodiment 2

[0040] 1) Add acrylamide (10.00mg), Bis / PEGDA700 (0.2mg) and photoinitiator 2959 (0.2mg) to water-dispersed silica nanoparticles (90μL, Ф152nm, 34vol%); obtain a prepolymer solution;

[0041] 2) Ultrasonic treatment of the prepolymer solution obtained in 1) for 5 minutes;

[0042] 3) On the basis of 2), the pre-polymerization solution is evenly penetrated into the space between the two parallel glasses separated by capillary force, the gap thickness is 50 μm, and then exposed to λ=365nm ultraviolet light for 10s, 30s, 45s, 60s, 120s to photopolymerize the monomer; thus obtain hydrogel films of different colors and hardness;

[0043] 4) In order to increase cell affinity, gelatin was grafted onto the surface of the hydrogel membrane of 3). The hydrogel membranes were then sterilized in 75% ethanol in Petri dishes, in sterile PBS for at least 3 hours and in cell culture medium for 1 hour; the cell culture medium was removed and fresh cell culture medium was injected.

[0044] ...

Embodiment 3

[0046] 1) Acrylamide (14.00mg), 7-acryloyloxyamino-4-methylcoumarin (2.00mg), Bis / PEGDA700 (0.45mg) and photoinitiator 2959 (0.45mg) were added to dimethyl ethylene Sulfone-dispersed silica nanoparticles (120 μL, Ф152 nm, 26 vol%); to obtain a prepolymer solution.

[0047] 2) Ultrasonic treatment of the prepolymer solution obtained in 1) for 5 minutes;

[0048] 3) On the basis of 2), the pre-polymerization solution is evenly penetrated into the space between two parallel glasses separated by capillary force, the gap thickness is 75 μm, and then exposed to λ=365nm ultraviolet light for 5 minutes to photopolymerize the monomer ; thereby obtaining a phototunable hydrogel film.

[0049] 4) To increase cell affinity, gelatin was grafted onto the surface of the hydrogel membrane. The hydrogel membranes were then sterilized in 75% ethanol in Petri dishes for at least 3 h in sterile PBS and 1 h in cell culture medium. Remove cell culture medium and inject new cell culture medium. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com