Treatment method and device of waste water containing ammonia

A treatment method and wastewater treatment technology, which are applied in water/sewage treatment, multi-stage water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of large steam consumption and disadvantages, and achieve low equipment investment and low treatment cost. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

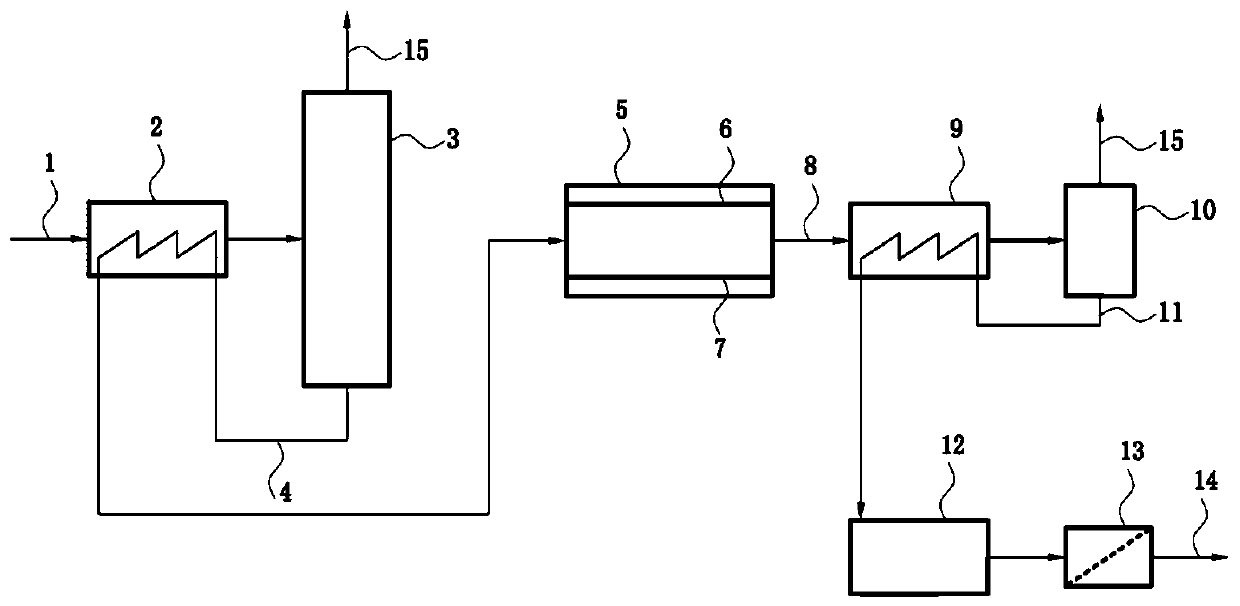

[0031] This embodiment is an embodiment of the residual ammonia treatment in the coking industry, and the technological process is as follows figure 1shown. Ammonia-containing waste water raw water 1 (residual ammonia water) is heated to 90°C by a heat source in the preheater 2, and then sent to the distillation tower 3 to separate the ammonia and volatile organic compounds contained in the liquid phase from the liquid phase, and the ammonia in the effluent Concentration drops below 600mg / l. The liquid phase is heated at the bottom of the distillation tower (not shown in the figure), and the raw water discharged from the bottom of the distillation tower is heated up to remove the ammonia wastewater 4 and exchange heat with the remaining ammonia water, which is used as a preheating heat source for the remaining ammonia water, and the ammonia-containing waste water is discharged from the top of the distillation tower The gas 15 is sent to the gas system after being condensed, a...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, except that the remaining ammonia water is heated to 80°C by the heat source in the preheater and then sent to the evaporator (with figure 1 The middle distillation tower has the same function) in which the ammonia and volatile organic compounds contained in the liquid phase are separated from the liquid phase, the ammonia concentration in the effluent is reduced to below 800mg / l, and the gas at the top of the evaporator is condensed and sent to the gas system. There is steam heating at the bottom of the evaporation tower to keep the liquid phase temperature in the evaporation tower at 100°C, and the liquid discharged from the evaporator exchanges heat with the remaining ammonia raw water and is used as a preheating heat source for the remaining ammonia water. After heat exchange with the remaining ammonia water, the temperature of the heated deamination wastewater cooled down to 40°C enters the electrochemical treat...

Embodiment 3

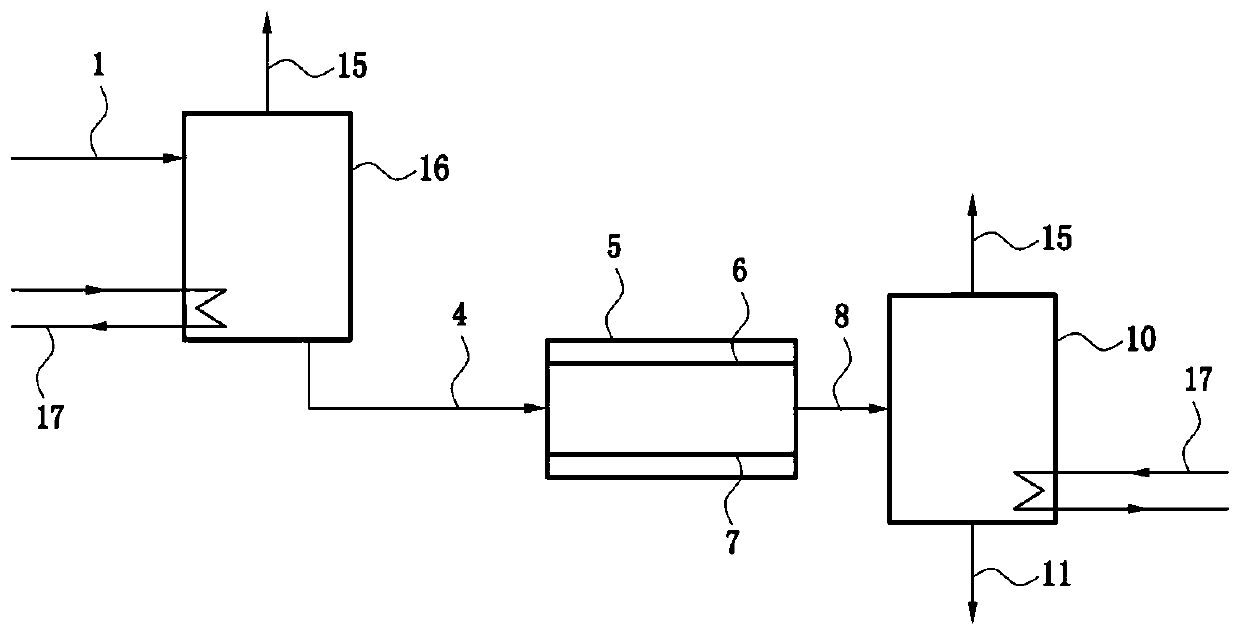

[0037] This example is basically the same as Example 2, except that the coking residual ammonia water is heated to 98°C by the heat source in the preheater and then sent to the evaporator to combine the ammonia and volatile organic compounds contained in the liquid phase with the liquid phase. Separation, the concentration of ammonia in the effluent is reduced to below 500mg / l, and the bottom of the evaporation tower is heated by steam to keep the liquid phase temperature in the evaporation tower at 130°C. The electrochemically treated ammonia-containing wastewater is preheated and then sent to the electrochemically treated water evaporator. The ammonia concentration in the ammonia-containing wastewater is reduced to 150mg / l and then enters the biochemical system as biochemically treated water. The heating source is electrochemically treated. The water is discharged from the water evaporator, and the maximum temperature of the liquid phase of the electrochemically treated water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com