Detection method of sugammadex sodium

A technology of sugammadex sodium and a detection method, which is applied in the directions of measuring devices, instruments, scientific instruments, etc., can solve the problems of low sensitivity, cannot achieve effective separation of sugammadex sodium, and achieves good specificity and high accuracy. , the effect of high separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

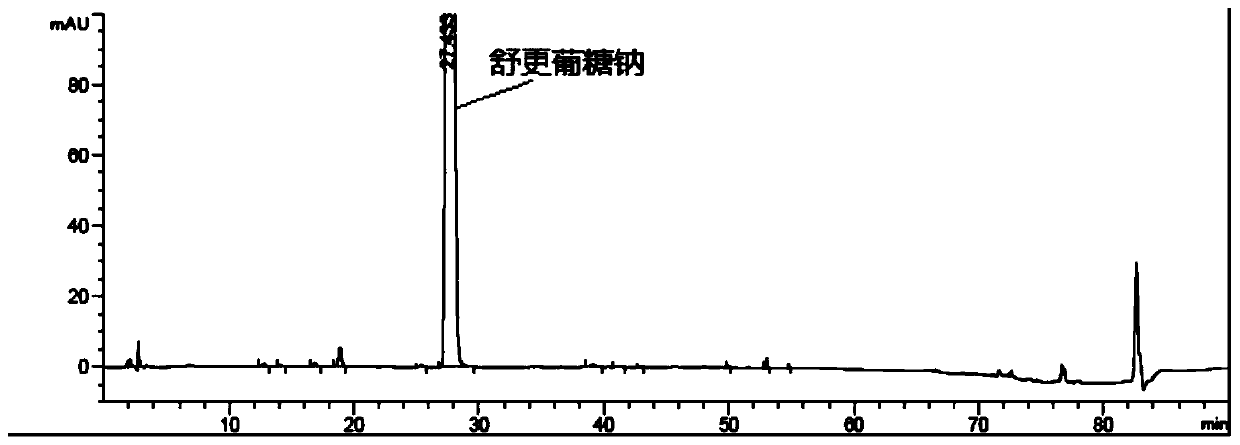

Embodiment 1

[0079] Preparation of system suitability solution:

[0080] Dissolve the sugammadex sodium sample and impurities 1-20 in the same solvent as mobile phase A to obtain a mixed solution, wherein the concentration of sugammadex sodium in the mixed solution is 5 mg / ml, and the concentration of impurities 1-20 5 μg / ml respectively.

[0081] The system suitability solution is injected into the liquid chromatograph, wherein the chromatographic conditions are:

[0082] Column: C 18 Chromatographic column (YMC ODS-AQ 150×4.6mm, 3μm);

[0083] Mobile phase A: configure 20mmol / L potassium dihydrogen phosphate solution, and adjust the pH value to 2.3 with phosphoric acid;

[0084] Mobile phase B: acetonitrile;

[0085] UV detection wavelength: 200nm;

[0086] Flow rate: 0.8ml / min

[0087] Column temperature: 40°C;

[0088] Gradient elution program:

[0089] time (minutes) Mobile phase A(%) Mobile phase B(%) 0 83 17 10 83 17 40 80 20 50 75 25 ...

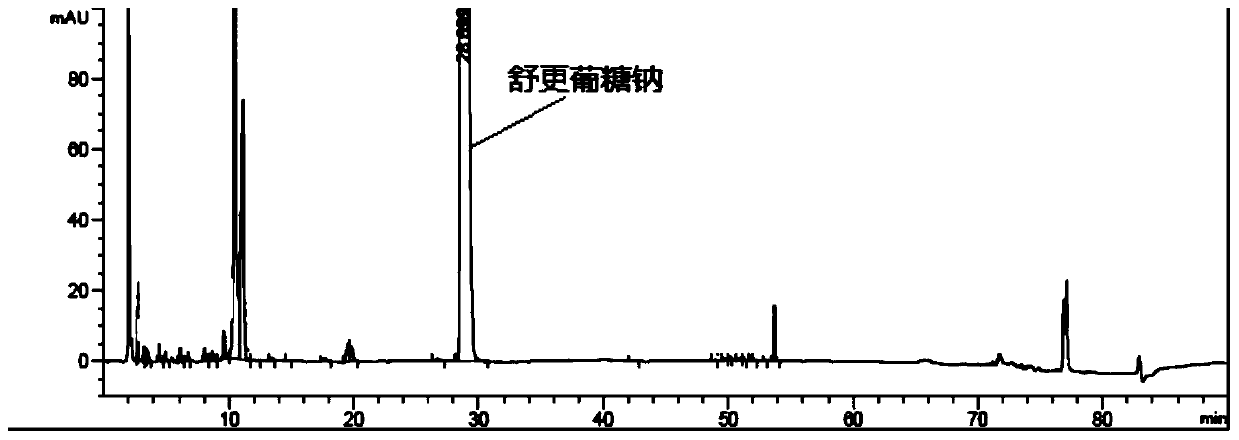

Embodiment 2

[0091] Example 2 is basically the same as Example 1, except that the pH value of mobile phase A is adjusted to 2.4 with phosphoric acid.

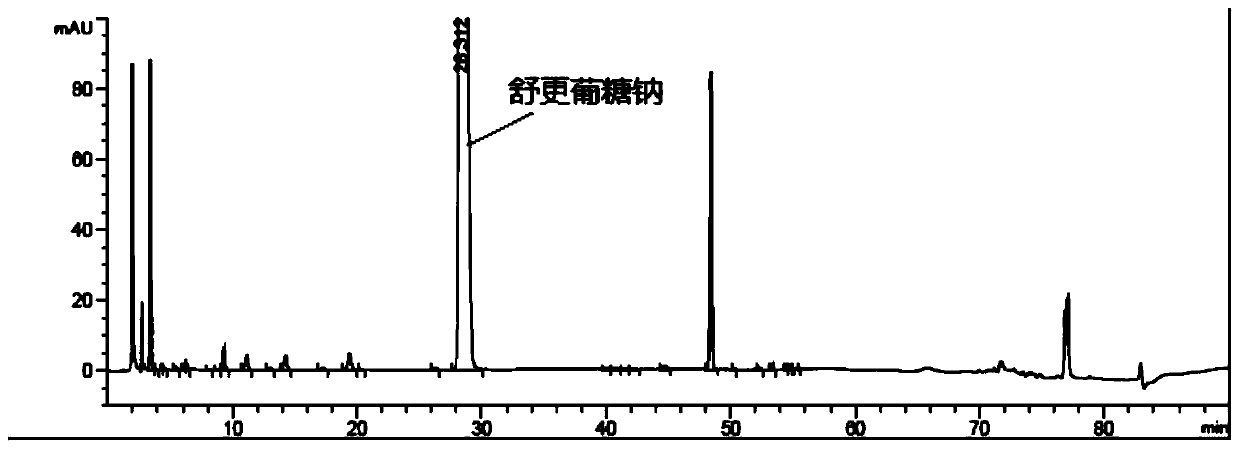

Embodiment 3

[0093] Example 3 is basically the same as Example 1, except that the pH value of mobile phase A is adjusted to 2.5 with phosphoric acid. Embodiment 1 to embodiment 3 each impurity separation situation is as shown in table 1:

[0094] Table 1

[0095]

[0096]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com