Method for preparing isosorbide by using perfusion reactive distillation device

A technology of reactive distillation and isosorbide, which is applied in the chemical industry, can solve problems such as the difficulty of reusing liquid acid, increasing operation time and cost, and not being suitable for continuous production, and achieves intensive utilization of heat energy, reduction of energy consumption, and energy saving. small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

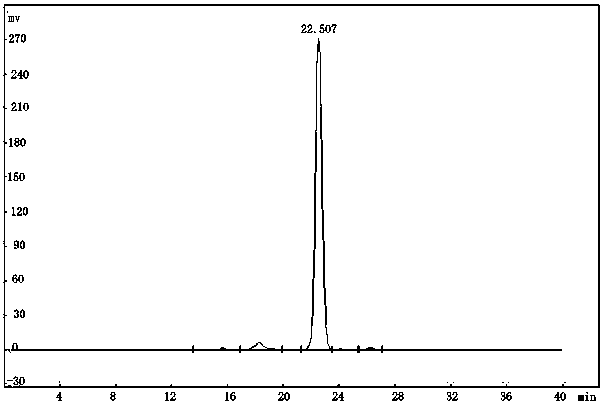

Embodiment 1

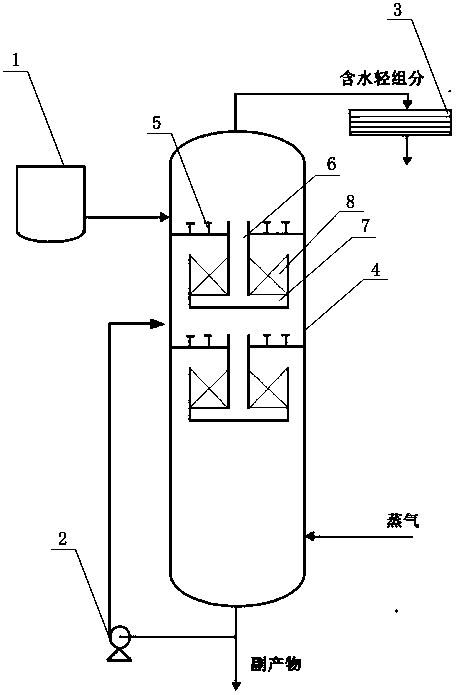

[0031] A method for preparing isosorbide using a perfusion reactive distillation device. The method uses solid sorbitol as a raw material. After heating and melting, the reaction and separation are carried out simultaneously in a perfusion reactive distillation device filled with a catalyst. Through the reaction Continuous production is achieved by alternately performing multiple stages of rectification.

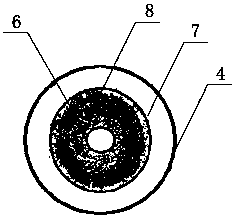

[0032] The perfusion reactive distillation device is composed of a preheater, a rectification tower and components thereof, a circulating pump, and a condenser; wherein, the preheater is connected to the upper part of the rectification tower with pipes, and several reactors and Tray, the reactor is located between two trays, and is coaxially connected with the central downcomer of the upper tray, and an overflow weir is provided at the connection between the tray and the central downcomer; the outlet at the bottom of the tower is respectively provided with a discharge pipe an...

Embodiment 2

[0040] The step of embodiment 2 is substantially the same as that of embodiment 1, the difference is: the feed rate of embodiment 2 is 0.7kg / h, the tower top temperature is 150 ℃, the tower bottom temperature is 200 ℃, the number of trays is 10, and the circulation pump flow rate 0.2kg / h; the catalyst is strip-shaped, and the diameter of the catalyst bed is 1.5mm. Described tray is valve tray; Described catalyst is WO 3 -ZrO 2 / Al 2 o 3 .

Embodiment 3

[0042] The step of embodiment 2 is substantially the same as that of embodiment 1, the difference is: embodiment 3 feed rate is 0.9kg / h, tower top temperature is 170 DEG C, tower bottom temperature is 220 DEG C, plate number is 12, circulation pump flow rate It is 0.3kg / h; the catalyst is granular, and the diameter of the catalyst bed is 2mm. Described tray is bubble cap tray; Described catalyst is WO 3 -ZrO 2 / SiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com