Polymer-coated carbon nano-tube composite material, preparation method and applications thereof

A composite material and nanotube technology, which is applied in the field of polymer-coated carbon nanotube composite materials to achieve the effect of overcoming poor electrical conductivity, excellent electrical conductivity and excellent superelectric properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

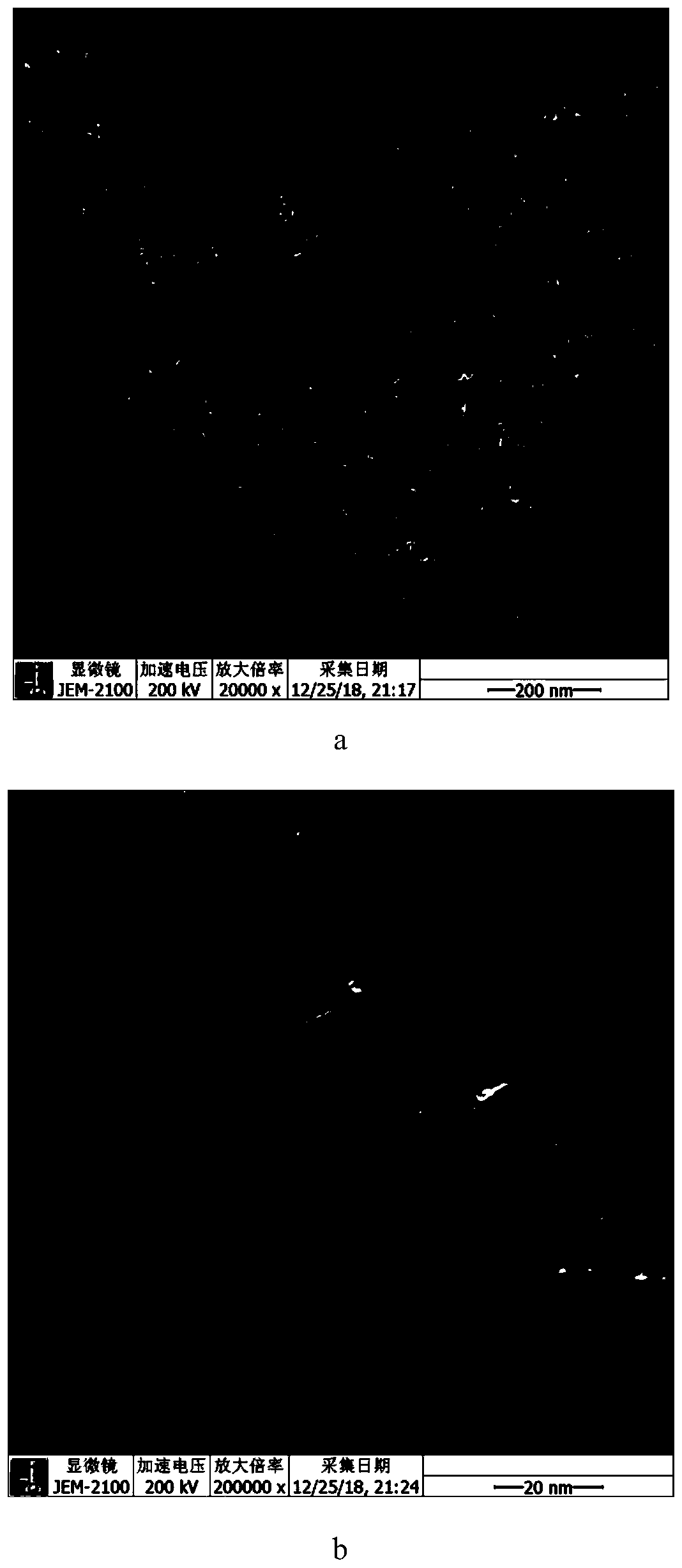

Image

Examples

Embodiment 1

[0029] (1) Dissolve 0.01 mmol of terephthalaldehyde in 30 mL of ethanol solution, stir at 35° C. for 10 minutes; slowly add 0.2 g of aminated carbon nanotubes dispersed in the terephthalaldehyde ethanol solution, and stir at room temperature for 10 minute.

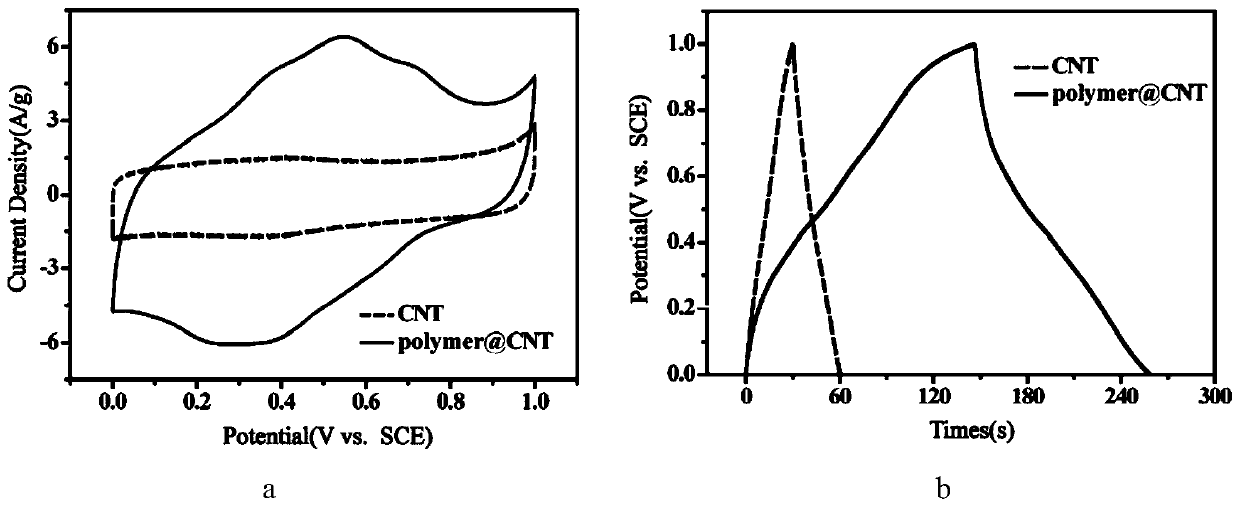

[0030] (2) Add 0.085mmol of 2,4,6-tris(4-aminophenyl)-1,3,5-triazine to the terephthalaldehyde ethanol solution in which the aminated carbon nanotubes are uniformly dispersed; stir at room temperature After 5 hours, the dark brown precipitate was centrifuged to obtain a polymer-coated carbon nanotube composite material. (Capacitance value: 112F / g)

Embodiment 2

[0032] (1) Dissolve 0.015 mmol of terephthalaldehyde in 50 mL of methanol solution, stir at 25°C for 10 minutes; slowly add 0.2 g of aminated carbon nanotubes dispersed in the terephthalaldehyde ethanol solution, and stir at room temperature for 15 minute.

[0033] (2) Add 0.01 mmol of 1,3,5-tris(4-aminophenyl)benzene to the terephthalaldehyde methanol solution in which the aminated carbon nanotubes are uniformly dispersed; stir at room temperature for 6 hours, centrifuge the dark brown precipitate, A composite material of polymer-coated carbon nanotubes is obtained. (Capacitance value: 90F / g)

Embodiment 3

[0035] (1) Dissolve 0.02mmol of 1,3,5-tris(4-formylphenyl)benzene in 60mL of tetrahydrofuran / ethanol mixed solution, stir at 30°C for 10 minutes; slowly add 0.12g of aminated carbon nanotubes to disperse in 1,3,5-tris(4-formylphenyl)benzenetetrahydrofuran / ethanol solution and stirred at room temperature for 15 minutes.

[0036] (2) Add 0.025 mmol of 1,3,5-tris(4-aminophenyl)benzene to the terephthalaldehyde ethanol solution in which the aminated carbon nanotubes are uniformly dispersed; stir at room temperature for 7 hours, centrifuge the dark brown precipitate, A composite material of polymer-coated carbon nanotubes is obtained. (Capacitance value: 100F / g)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com