Protein nano-film based on sulfhydryl and disulfide bond exchange reaction, and application thereof

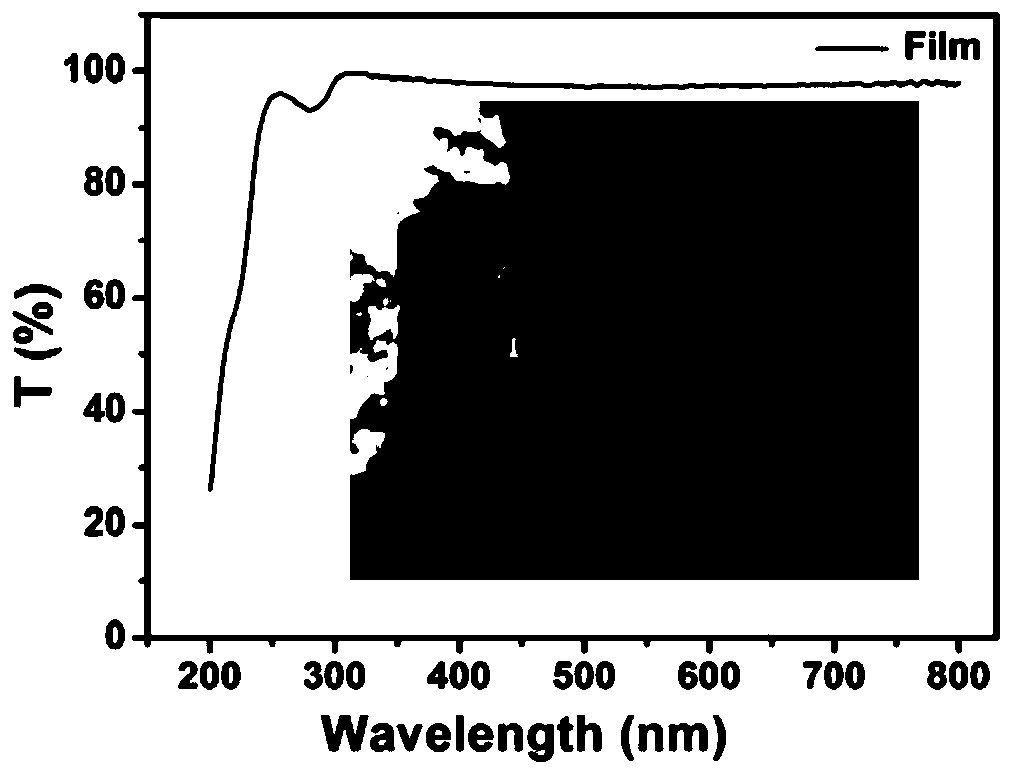

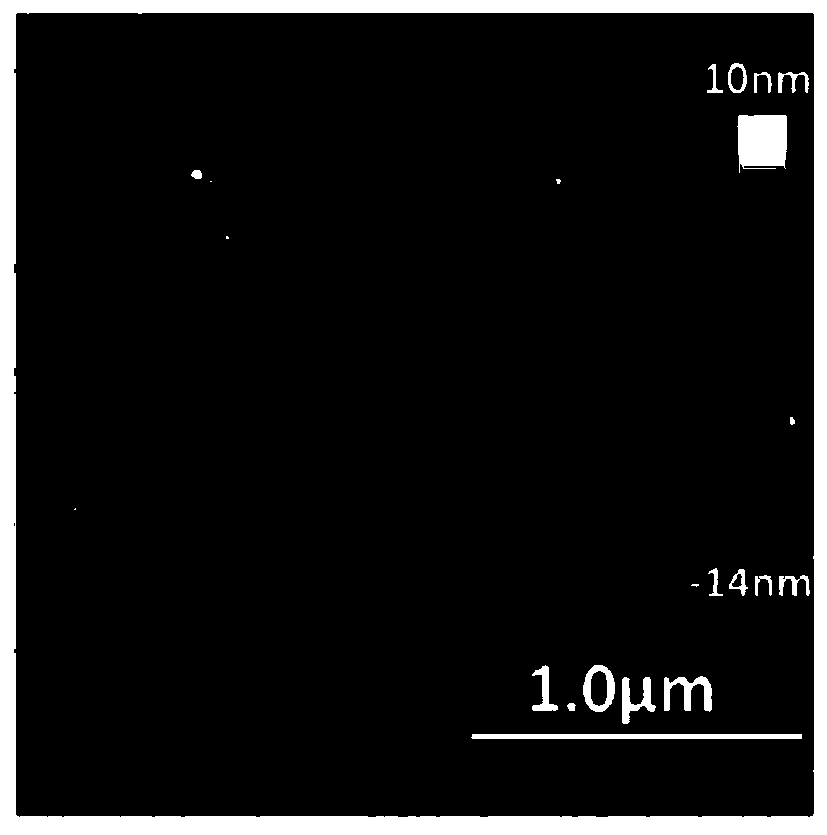

A nano-membrane and exchange reaction technology, which is applied in the direction of peptide/protein components, medical preparations containing active ingredients, non-effective ingredients of polymer compounds, etc., can solve the problem of limited dual control ability of structure and function, lagging development of synthetic substitutes, Low film strength and other problems, to achieve excellent optical transparency, good chemical stability and mechanical stability, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] At room temperature, add 50 mg of L-cysteine to 10 mL of 4-hydroxyethylpiperazineethanesulfonic acid buffer solution with a pH of 7.4 and adjust the pH to 8 to 10 with 5 mol / L aqueous sodium hydroxide solution. Add lysozyme to 10mL of 4-hydroxyethylpiperazineethanesulfonic acid buffer solution with a pH of 7.4, and then mix the two solutions evenly to obtain a mixed solution; drop the mixed solution on the surface of the glass slide or turn the glass slide upside down On the surface of the mixed solution droplet, a layer of protein nanofilm was clearly formed at the gas-liquid interface of the glass sheet or a layer of protein nanofilm was formed at the solid-liquid interface between the inverted glass sheet and the mixed solution droplet within 60 minutes.

Embodiment 2

[0024] At room temperature, add 70 mg of L-cysteine into 10 mL of 4-hydroxyethylpiperazineethanesulfonic acid buffer solution with a pH of 7.4 and adjust the pH to 8 to 10 with 5 mol / L aqueous sodium hydroxide solution. Add lysozyme to 10 mL of 4-hydroxyethylpiperazineethanesulfonic acid buffer solution with a pH of 7.4, and then mix the two solutions evenly to obtain a mixed solution; add the mixed solution dropwise on the surface of the glass slide or place the glass slide upside down on the On the surface of the mixed solution droplet, a layer of protein nanofilm is clearly formed on the gas-liquid interface of the glass sheet within 60 minutes or a layer of protein nanofilm is formed on the solid-liquid interface between the inverted glass sheet and the mixed solution drop (see Figure 1~2 ).

Embodiment 3

[0026] At room temperature, add 100 mg of L-cysteine into 10 mL of 4-hydroxyethylpiperazineethanesulfonic acid buffer solution with a pH of 7.4 and adjust the pH to 8 to 10 with 5 mol / L aqueous sodium hydroxide solution. Add lysozyme to 10mL of 4-hydroxyethylpiperazineethanesulfonic acid buffer solution with a pH of 7.4, and then mix the two solutions evenly to obtain a mixed solution; drop the mixed solution on the surface of the glass slide or turn the glass slide upside down On the surface of the mixed solution droplet, a layer of protein nanofilm was clearly formed at the gas-liquid interface of the glass sheet or a layer of protein nanofilm was formed at the solid-liquid interface between the inverted glass sheet and the mixed solution droplet within 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com