High-heat-conductivity polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, applied in the field of high thermal conductivity polypropylene composite material and its preparation, can solve problems such as poor mechanical properties and poor flow properties, achieve good compatibility, improve thermal conductivity, improve fluidity and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

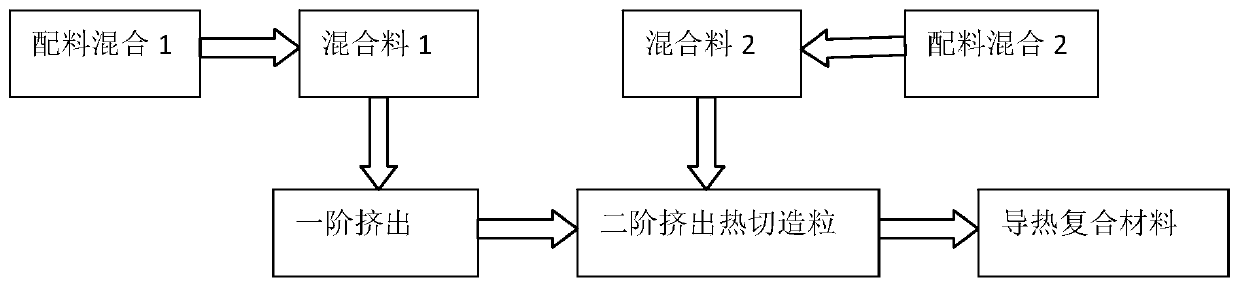

Method used

Image

Examples

Embodiment 1

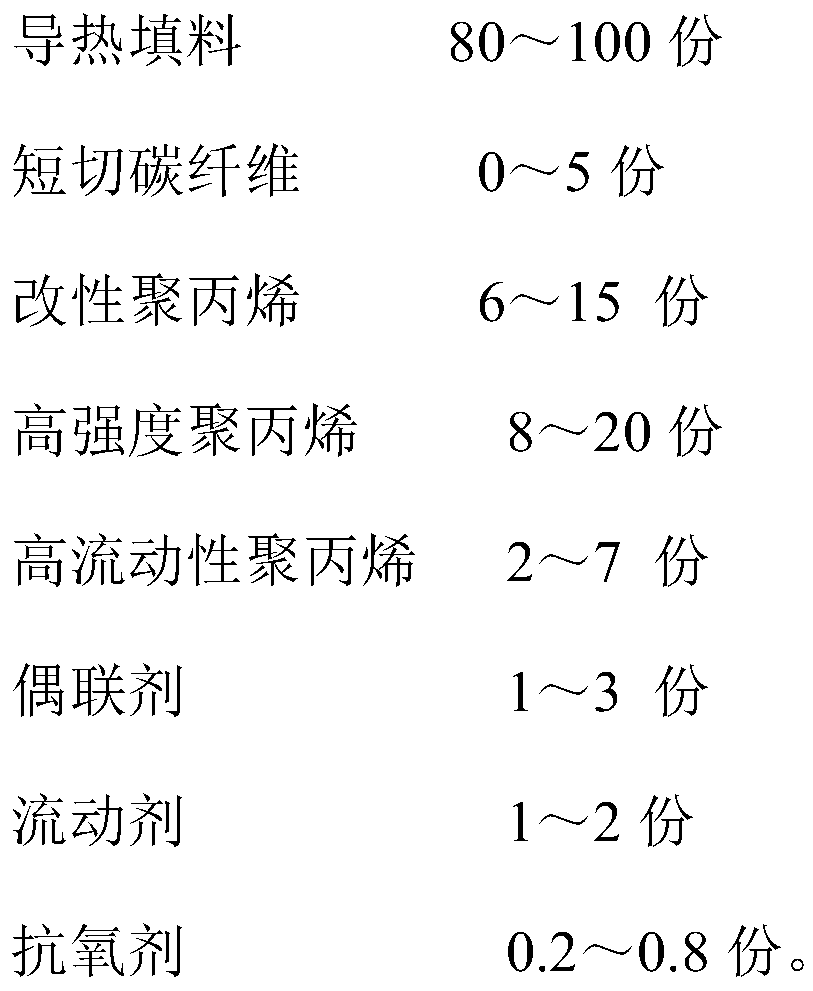

[0036] The high thermal conductivity polypropylene composite material, by weight, consists of raw materials:

[0037]

[0038] (1) carry out coupling agent surface treatment to graphite powder and graphite sheet, obtain modified graphite powder and graphite sheet;

[0039] (2) The modified graphite powder and the modified graphite sheet are mixed with maleic anhydride grafted polypropylene, 0.5 part of flow agent, and 5 parts of high fluidity polypropylene at high speed to obtain compound 1;

[0040] (3) High-strength polypropylene, chopped carbon fiber, 2 parts of high-fluidity polypropylene, 0.5 part of flow agent, and antioxidant are mixed at high speed to obtain a mixture 2;

[0041] (4) Second-stage continuous extrusion compound granulation: fully knead and plasticize the compound 1 in the first-stage twin-screw extruder, control the temperature of the melt at 180-250°C, and enter the second-stage twin-screw extruder after mixing. Out of the feeding port of the machin...

Embodiment 2

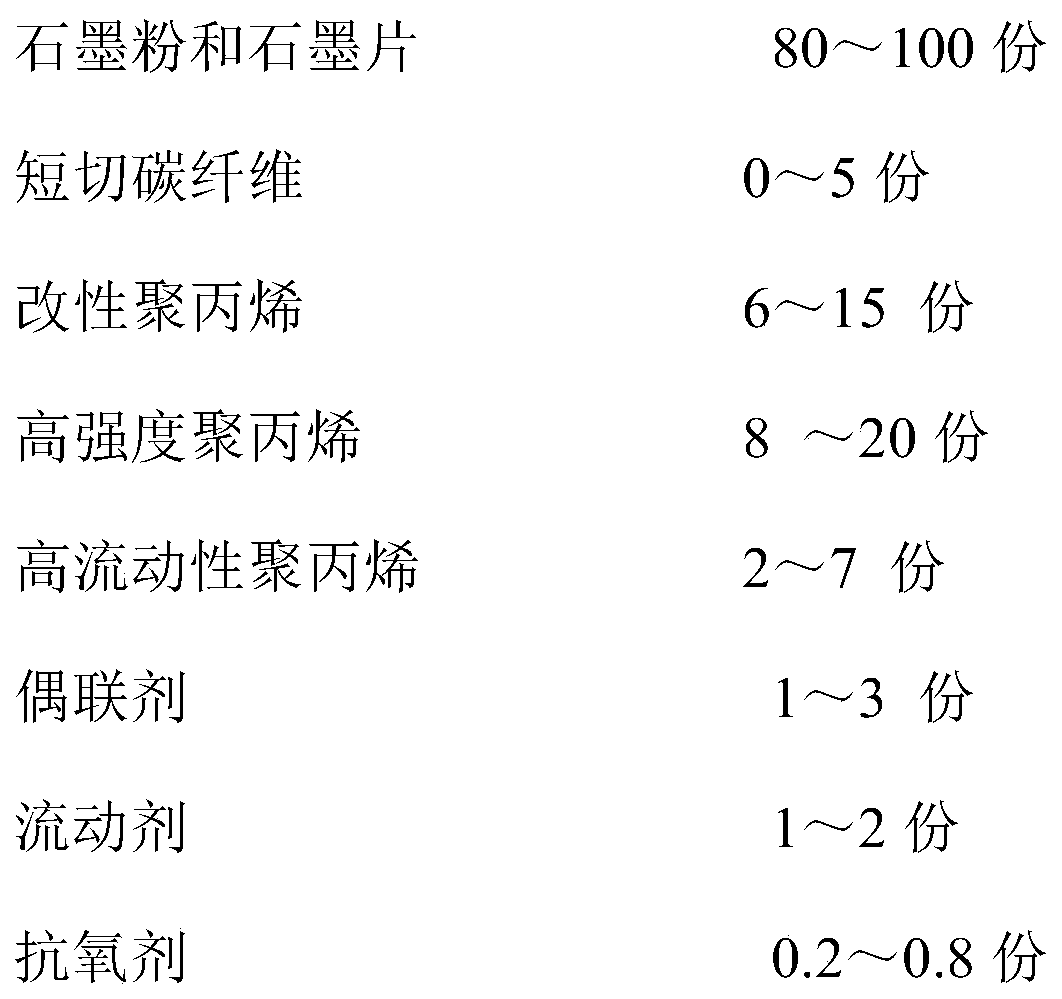

[0043]

[0044] Second-stage continuous extrusion compound granulation was adopted, and the preparation process was the same as in Example 1 to obtain a high thermal conductivity polypropylene composite material.

Embodiment 3

[0046]

[0047]

[0048] Second-stage continuous extrusion compound granulation was adopted, and the preparation process was the same as in Example 1 to obtain a high thermal conductivity polypropylene composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com