Preparation method of flame retardant material

A technology of flame retardant materials and flame retardants, applied in the field of flame retardant materials, can solve the problems of poor hydrolysis resistance, poor high temperature resistance, low phosphorus content, etc., achieve excellent flame retardant performance, increase thermal degradation temperature, and high melting point Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

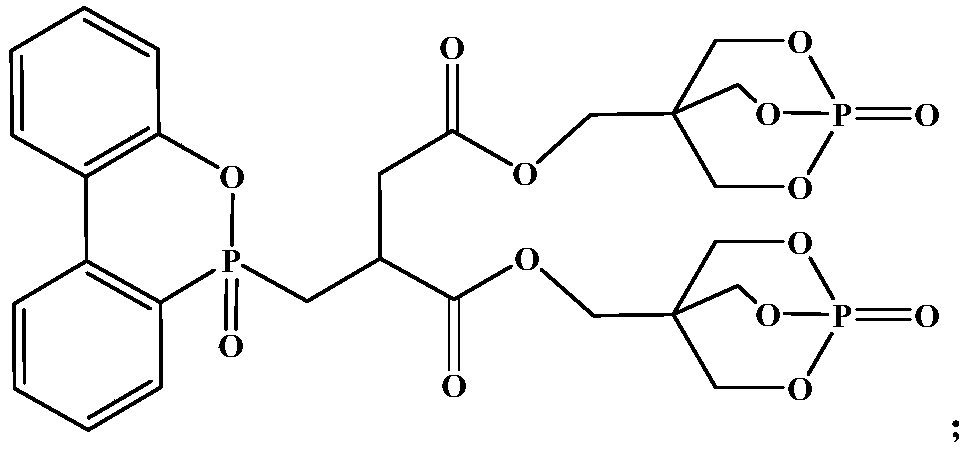

[0029] A high phosphorus content hydrolysis-resistant flame retardant, its preparation method is as follows:

[0030] (1) Preparation of hydroxylated DDP: DDP and ethylene glycol with a molar ratio of 1:2.50 are used as raw materials, and under the protection of nitrogen, esterification reaction is carried out, accompanied by vacuum distillation, to obtain hydroxylated DDP , wherein, the temperature of the esterification reaction is 160°C, the time is 3.5h, and the vacuum degree of the vacuum distillation is 5KPa;

[0031] (2) Preparation of high-phosphorus-content hydrolysis-resistant flame retardant: using hydroxylated DDP with a molar ratio of 1:2.00 and caged pentaerythritol phosphate as raw materials, under the protection of nitrogen, first carry out high-pressure transesterification reaction, and then carry out vacuum Transesterification reaction to produce a high phosphorus content hydrolysis-resistant flame retardant, wherein the temperature of the high-pressure transe...

Embodiment 2

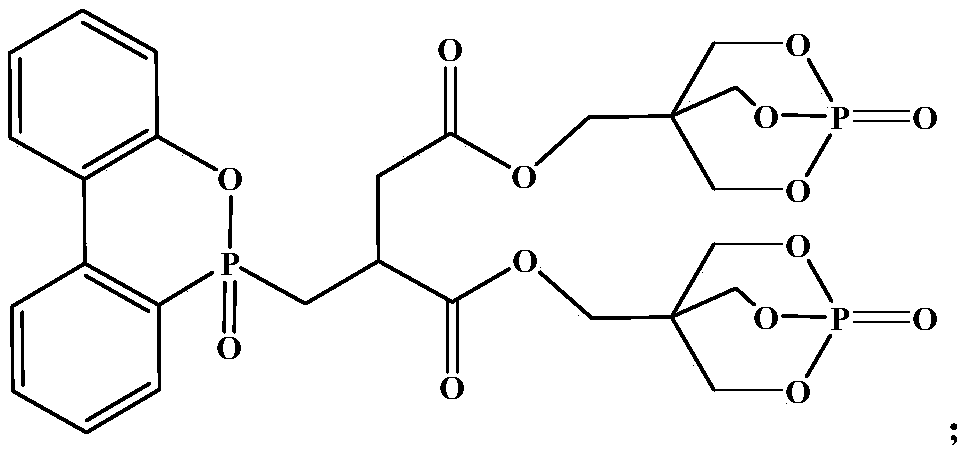

[0036] A high phosphorus content hydrolysis-resistant flame retardant, its preparation method is as follows:

[0037] (1) Preparation of hydroxylated DDP: use DDP and ethylene glycol with a molar ratio of 1:3.00 as raw materials, under the protection of nitrogen or inert gas, carry out esterification reaction, accompanied by vacuum distillation, to obtain terminal hydroxyl The converted DDP, wherein the temperature of the esterification reaction is 180°C, the time is 1.0h, and the vacuum degree of the vacuum distillation is 10KPa;

[0038] (2) Preparation of high-phosphorus content hydrolysis-resistant flame retardant: use hydroxylated DDP and caged pentaerythritol phosphate with a molar ratio of 1:2.01 as raw materials, and under the protection of nitrogen, perform high-pressure transesterification first, and then vacuum transesterification reaction to produce a high phosphorus content hydrolysis-resistant flame retardant, wherein the temperature of the high-pressure transest...

Embodiment 3

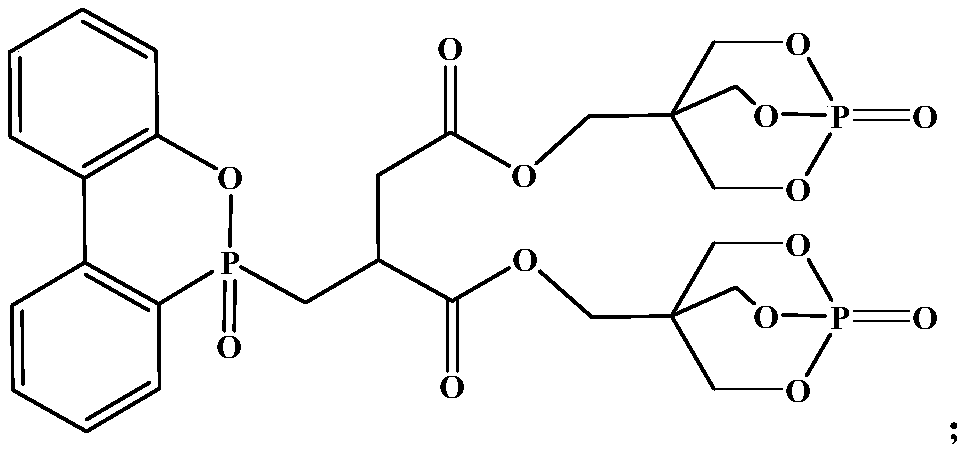

[0043] A high phosphorus content hydrolysis-resistant flame retardant, its preparation method is as follows:

[0044] (1) Preparation of hydroxylated DDP: DDP and ethylene glycol with a molar ratio of 1:2.50 are used as raw materials, and under the protection of nitrogen, esterification reaction is carried out, accompanied by vacuum distillation, to obtain hydroxylated DDP , wherein, the temperature of the esterification reaction is 175°C, the time is 2.5h, and the vacuum degree of the vacuum distillation is 8KPa;

[0045] (2) Preparation of high-phosphorus content hydrolysis-resistant flame retardant: use hydroxylated DDP and caged pentaerythritol phosphate with a molar ratio of 1:2.01 as raw materials, and under the protection of nitrogen, perform high-pressure transesterification first, and then vacuum Transesterification reaction to produce a high phosphorus content hydrolysis-resistant flame retardant, wherein the temperature of the high-pressure transesterification react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com