High-stability perovskite quantum dot composite material and preparation method thereof

A composite material and quantum dot technology, which is applied in the field of perovskite quantum dot composite material Al2O3/CsPbX3 and its preparation, can solve the lack of detailed research on the stability improvement mechanism of semi-bare QDs and hinder the charge transfer of perovskite QDs and other semiconductors , affect photoelectric applications and other issues, to achieve the effect of highlighting water stability and thermal stability, excellent stability, and excellent luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

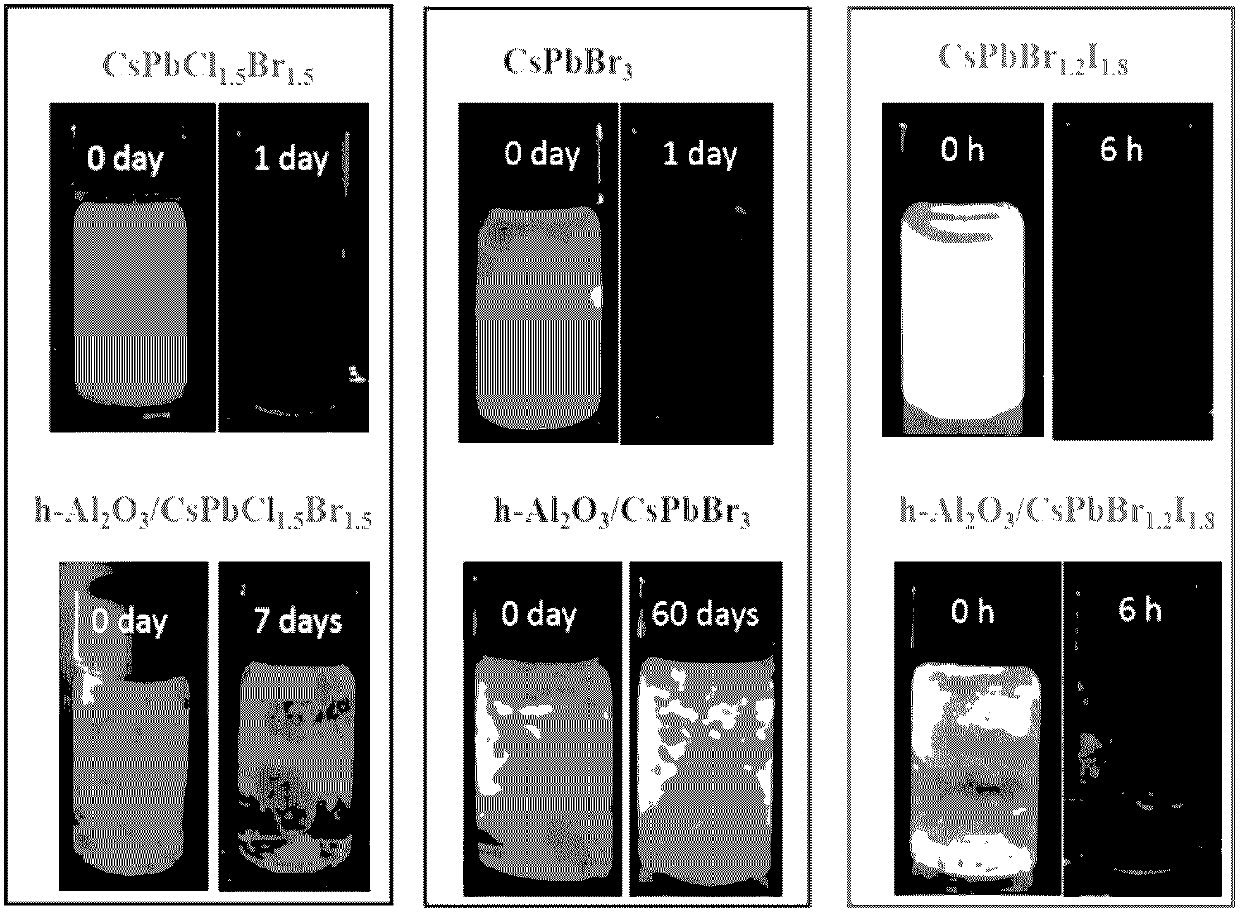

[0025] Example 1: Preparation of Al 2 O 3 / CsPbCl 1.5 Br 1.5 Composite materials.

[0026] S1: 0.267g Cs 2 CO 3 , 10ml octadecene and 1ml oleic acid are placed in a 50ml three-necked flask. Under stirring at room temperature, pass 10 min N 2 Then the temperature was raised to 120°C and degassed under vacuum for about 1 hour until no bubbles were generated. Then, enter N again 2 , While heating to 150℃, wait for Cs 2 CO 3 After dissolving completely, cool to room temperature naturally. Since cesium oleate will precipitate out of octadecene at room temperature, it needs to be preheated to 100°C during use.

[0027] S2: Add 0.188 mmol PbCl 2 , 0.188 mmol PbBr 2 And 10 ml octadecene in a 50 ml three-necked flask. Under stirring at room temperature, pass 10 min N 2 Then the temperature was raised to 120°C and degassed under vacuum for about 1 hour until no bubbles were generated. Then, enter N again 2 , Inject 1 ml each of oleic acid and oleylamine. PbCl 2 And PbBr 2 After completel...

example 2

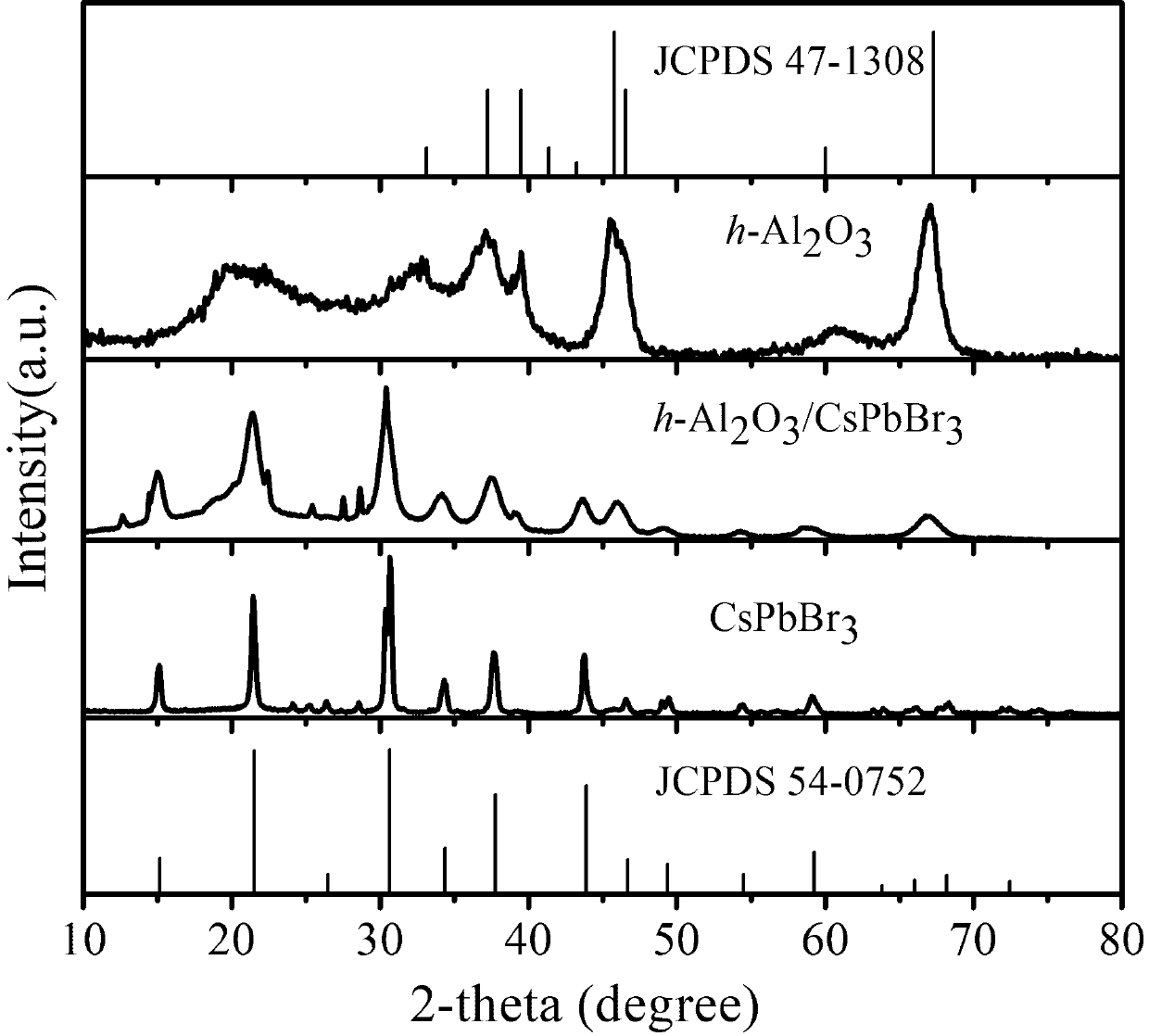

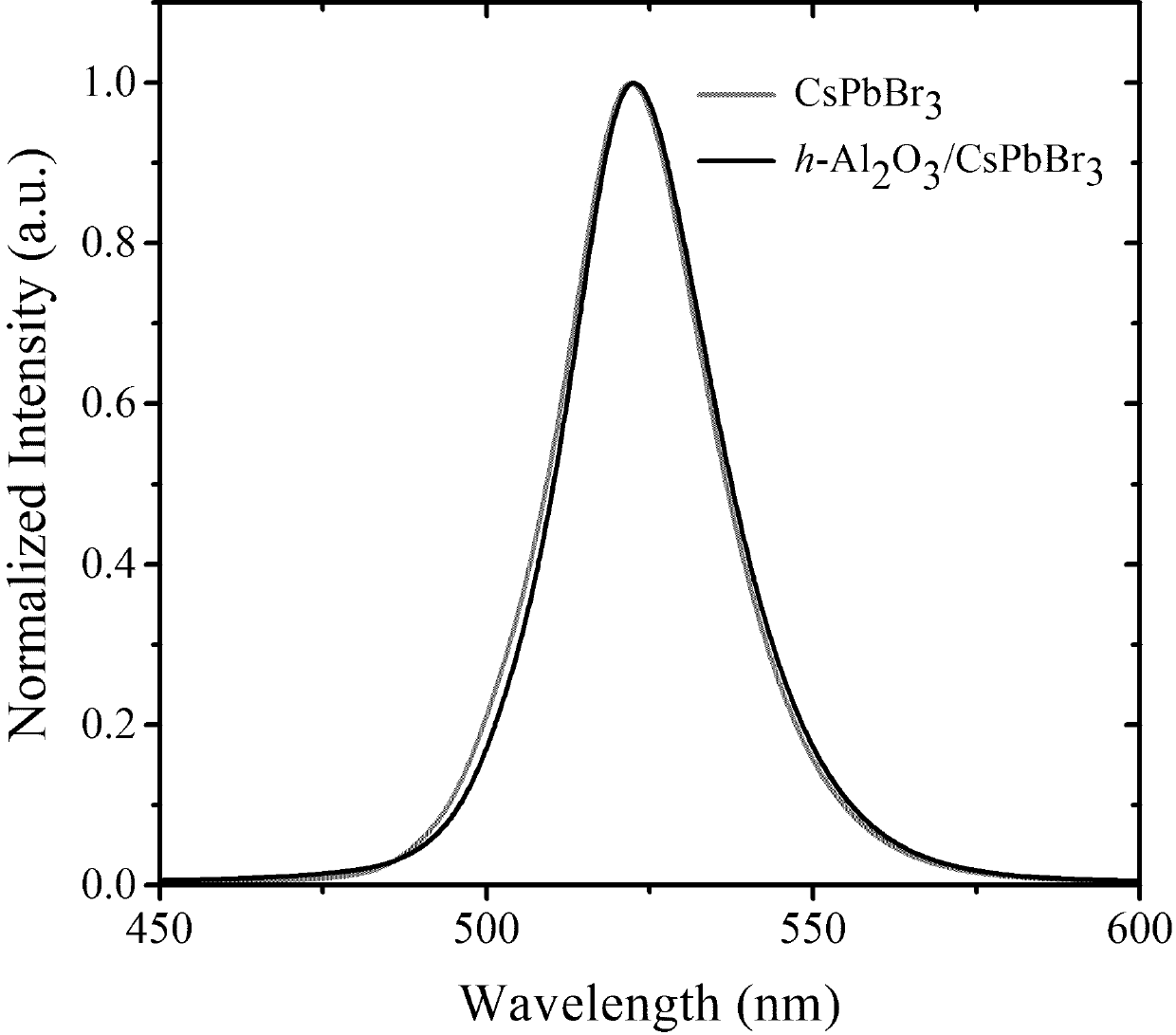

[0032] Example 2: Preparation of Al 2 O 3 / CsPbBr 3 Composite materials.

[0033] S1: 0.267g Cs 2 CO 3 , 10 ml octadecene and 1 ml oleic acid are placed in a 50 ml three-necked flask. Under stirring at room temperature, pass 10 min N 2 Then the temperature was raised to 120°C and degassed under vacuum for about 1 hour until no bubbles were generated. Then, enter N again 2 , While heating to 150℃, wait for Cs 2 CO 3 After dissolving completely, cool to room temperature naturally. Since cesium oleate will precipitate out of octadecene at room temperature, it needs to be preheated to 100°C during use.

[0034] S2: Add 0.376 mmol PbBr 2 And 10 ml octadecene in a 50 ml three-necked flask. Under stirring at room temperature, pass 10min N 2 Then the temperature was raised to 120°C and degassed under vacuum for about 1 hour until no bubbles were generated. Then, enter N again 2 , Inject 1 ml each of oleic acid and oleylamine. PbBr 2 After it is completely dissolved, the temperature is ...

example 3

[0039] Example 3: Preparation of Al 2 O 3 / CsPbBr 1.2 I 1.8 Composite materials.

[0040] S1: 0.267 g Cs 2 CO 3 , 10ml octadecene and 1ml oleic acid are placed in a 50ml three-necked flask. Under stirring at room temperature, pass 10 min N 2 Then the temperature was raised to 120°C and degassed under vacuum for about 1 hour until no bubbles were generated. Then, enter N again 2 , While heating to 150℃, wait for Cs 2 CO 3 After dissolving completely, cool to room temperature naturally. Since cesium oleate will precipitate out of octadecene at room temperature, it needs to be preheated to 100°C during use.

[0041] S2: Add 0.150 mmol PbBr 2 , 0.226 mmol PbI 2 And 10 ml octadecene in a 50 ml three-necked flask. Under stirring at room temperature, pass 10 min N 2 Then the temperature was raised to 120°C and degassed under vacuum for about 1 hour until no bubbles were generated. Then, enter N again 2 , Inject 1 ml each of oleic acid and oleylamine. PbBr 2 And PbI 2 After completely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com