Metal prefabricated material and manufacturing method thereof

A metal, metal-based technology, applied in the field of materials, to achieve the effect of reducing thickness, reducing thickness and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: The manufacturing method of the high-strength DP dual-phase steel metal prefabricated material plate based on fractional selective laser quenching.

[0046] The dual-phase steel is mainly composed of ferrite (F) and martensite (M), and the martensite is dispersed in the ferrite matrix in an island shape, with low yield strength and yield ratio, and high deformation hardening Index, DP series high-strength steel is widely used in automotive structural parts, such as: door anti-collision beams, door sill reinforcement plates, seat brackets, etc.

[0047] In this embodiment, a DP dual-phase steel plate (ordinary cold-rolled steel plate, cold-rolled galvanized steel plate) with a thickness of 1.6 mm is used as a raw material, and a high-power fiber laser is used as a heat source, and the laser power density is 1.5×10 4 W / cm 2 ~2.2×10 4 W / cm 2 , the diameter of the spot is 5mm, and the two sides of the steel plate are respectively subjected to selective lase...

Embodiment 2

[0052] Embodiment 2: Manufacture of 1000MPa dual-phase steel metal prefabricated material plate by selective laser quenching

[0053] 800DP dual-phase steel plate can be used to manufacture structural reinforcements for passenger cars, such as B-pillar / A-pillar reinforcement plates, cross beams, reinforced beam engine rear brackets, etc. In this embodiment, cold-rolled 800DP dual-phase steel sheets with a thickness of 0.8mm, 1.0mm, and 1.6mm are used as raw materials (which can be ordinary cold-rolled steel sheets or cold-rolled galvanized steel sheets), and high-power fiber lasers are used as heat sources. The power densities were 1.2×10 4 W / cm 2 , 2.0×10 4 W / cm 2 , 1.5×10 4 W / cm 2 , the single-side quenching depths are 0.4mm, 0.5mm, and 0.8mm respectively; the selective laser quenching treatment is performed on one side of the first two steel plates, and the selective laser quenching treatment is performed on both sides of the latter steel plate. The diameter of the li...

Embodiment 3

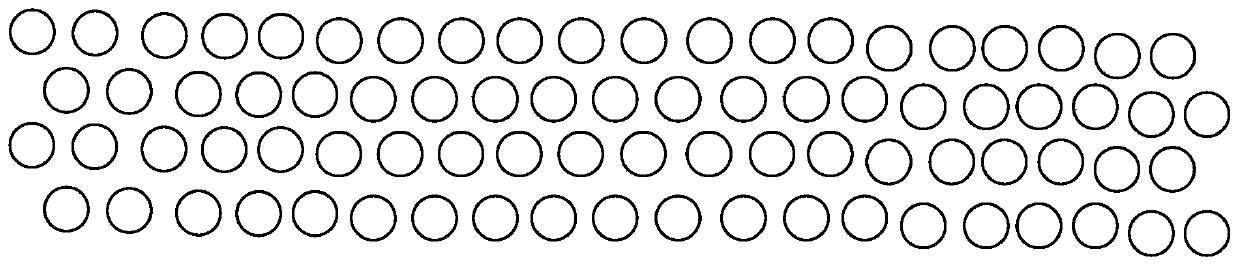

[0057] Embodiment 3: Selected area laser quenching manufactures metal prefabricated material carbon steel plate

[0058] According to different plate components and laser process parameters, metal matrix composites with different strengthening and toughening phase shapes, sizes, and distribution densities can be obtained based on selective laser quenching technology. The corresponding parameters are shown in Table 2. It can be seen that by selecting different matrix materials, spot diameters, power densities, distribution modes and densities of enhanced phases, fiber lasers and figure 1 As shown in the dot matrix pattern, the obtained allotropic metal matrix composites have large differences in strength and plasticity according to the size, density and mode of the second phase.

[0059] Table 2. Mechanical properties of metal matrix composite carbon steel plates obtained by selective laser quenching with different process parameters

[0060]

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| laser intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com