Cobaltocene cationic-based corrosion inhibitor as well as preparation method and application method

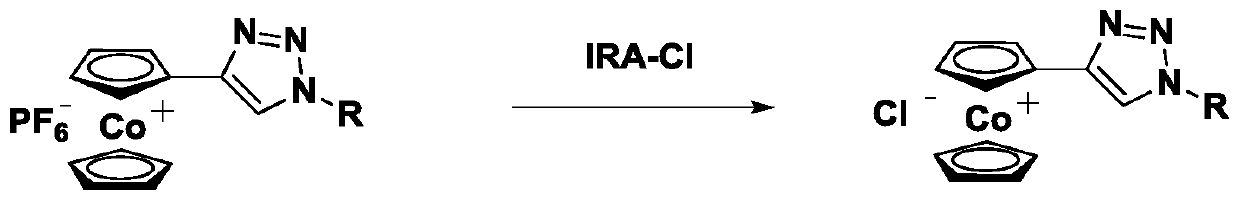

A cobaltocene-based cation and cation-based technology, which is applied to cobaltocene-based cation-based corrosion inhibitors and their preparation. Using cobaltocene-based cation-based compounds as hydrochloric acid corrosion inhibitors can solve the problem of high toxicity of inorganic corrosion inhibitors and water richness. Nutritization, not suitable for environmental protection and other problems, to achieve the effect of wide application temperature range, slow down corrosion, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Swell 2.0g of IRA-400(Cl) resin with water for 1-5h; dissolve 0.2g of cobaltocene hexafluorophosphate in 3-5mL of acetone to obtain solution A; pretreated IRA-400(Cl) ) resin was dissolved in 1 to 3 mL of deionized water; solution A was added dropwise and stirred at room temperature for 1 to 2 hours, the filtrate was collected by filtration, and the resin was washed with hot water for several times and combined with the filtrate; the concentrated solution was freeze-dried to obtain 81% of Ι -1 product.

[0048]The effect diagram of this embodiment:

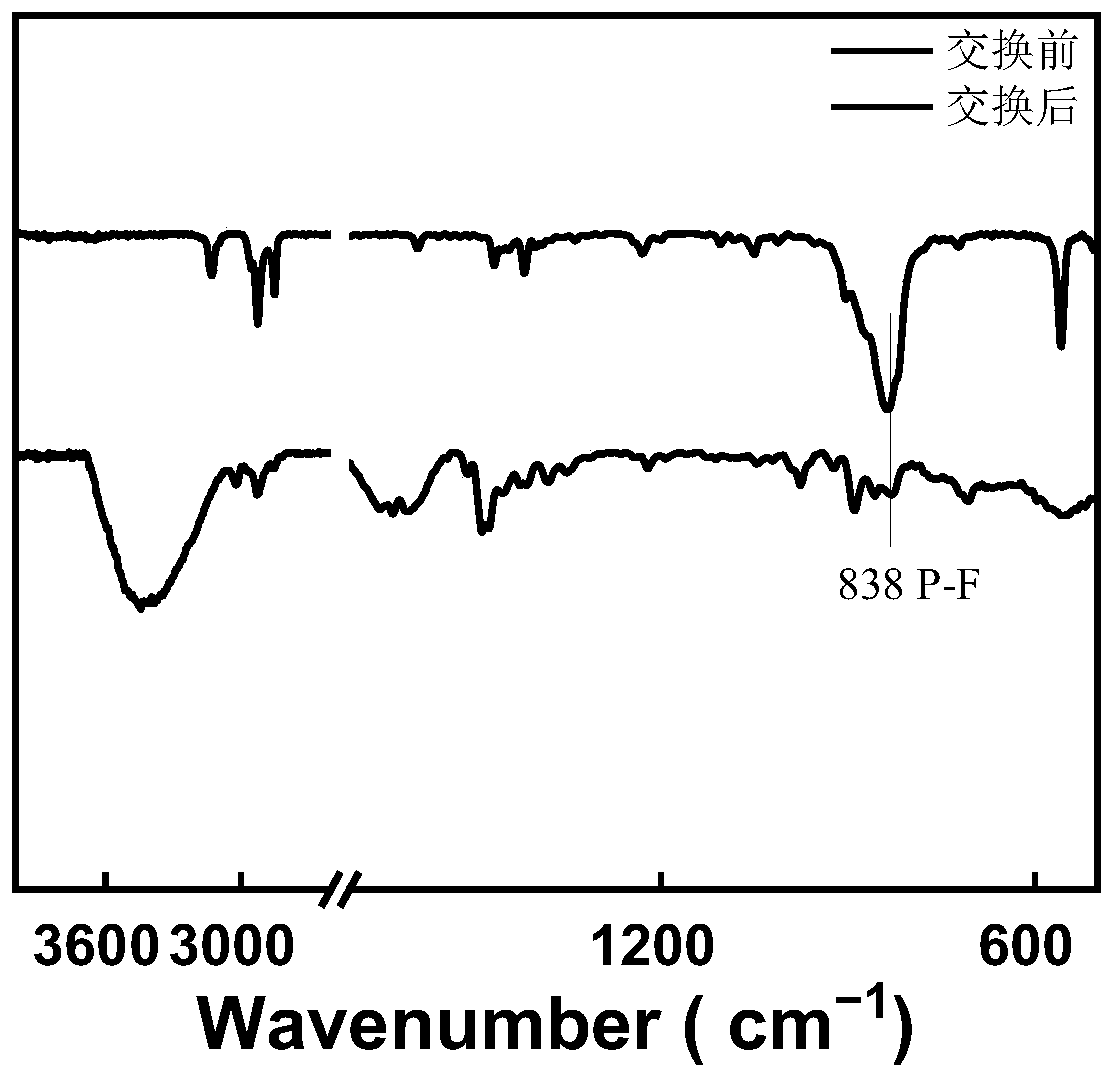

[0049] figure 2 It is the Fourier transform infrared spectrum before and after ion exchange of the cobaltocene-based corrosion inhibitor. Among them in 838cm -1 The disappearance of the P-F peak indicates that the cobaltocene-based corrosion inhibitor was successfully prepared.

[0050] image 3 It is a digital photo before and after ion exchange of the cobaltocene-based corrosion inhibitor.

[0051] Figure 4 It is...

Embodiment 2

[0054] The concentration of the hydrochloric acid solution is 4.0mol / L, the dosage of the hydrochloric acid solution is 150mL, and the cobaltocene-based corrosion inhibitor (R=-C 16 h 33 ) is 20mg / L, and 10# steel and 304 stainless steel are immersed in the acid solution for 2 hours at 25°C. The corrosion inhibition efficiencies (η) measured under these conditions are 88% and 70%, respectively.

Embodiment 3

[0056] The concentration of the hydrochloric acid solution is 4.0mol / L, the dosage of the hydrochloric acid solution is 150mL, and the cobaltocene-based corrosion inhibitor (R=-C 16 h 33 ) is 20mg / L, and 10# steel and 304 stainless steel are immersed in the acid solution for 4 hours at 25°C. The corrosion inhibition efficiencies (η) measured under these conditions are 95% and 79%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com