Preparation method for novel foam carbon electromagnetic shielding composite material

A composite material, electromagnetic shielding technology, applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, electrical components, etc., can solve the problems of general dispersion effect, can not ensure uniform dispersion of nanoparticles, and achieve enhanced electromagnetic shielding performance, electromagnetic shielding The effect of excellent performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

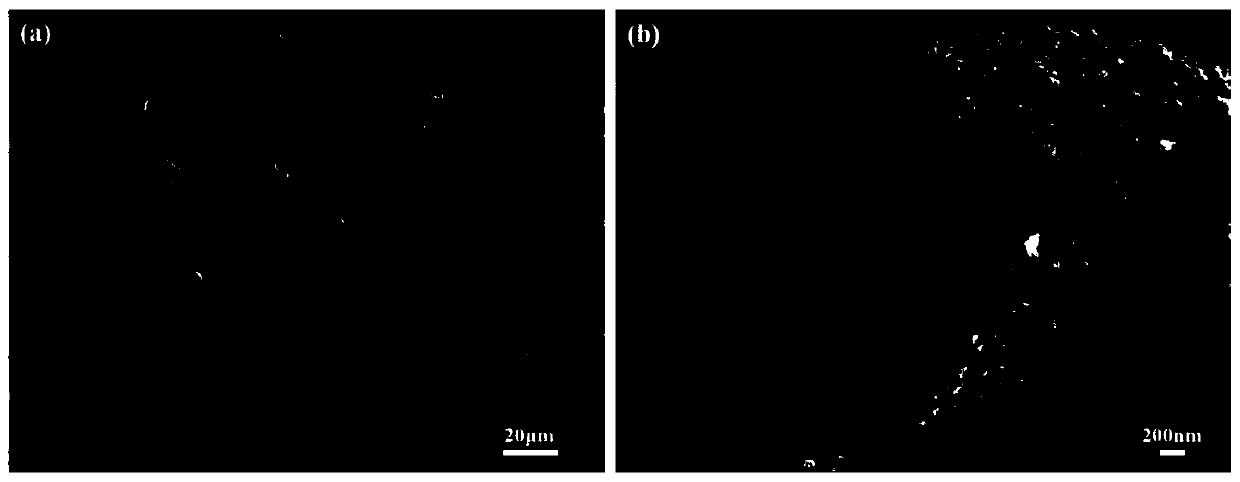

[0034] Step 1, pretreatment of melamine foam:

[0035] The melamine foam was ultrasonically cleaned with deionized water and absolute ethanol, respectively, for 30 minutes each, and then dried in an oven at a temperature of 90°C for 12 hours;

[0036] Step 2, place the pretreated melamine foam in step 1 in a tube furnace, 2 Multi-stage carbonization treatment is carried out under the protection of the atmosphere. The first stage is heated from room temperature to 200°C and kept for 1-2 hours; the second stage is heated to 400°C and kept for 1-2 hours; Control the cooling rate, cool the sample to room temperature, and the heating rate and cooling rate are both 5°C / min to prepare foamed carbon;

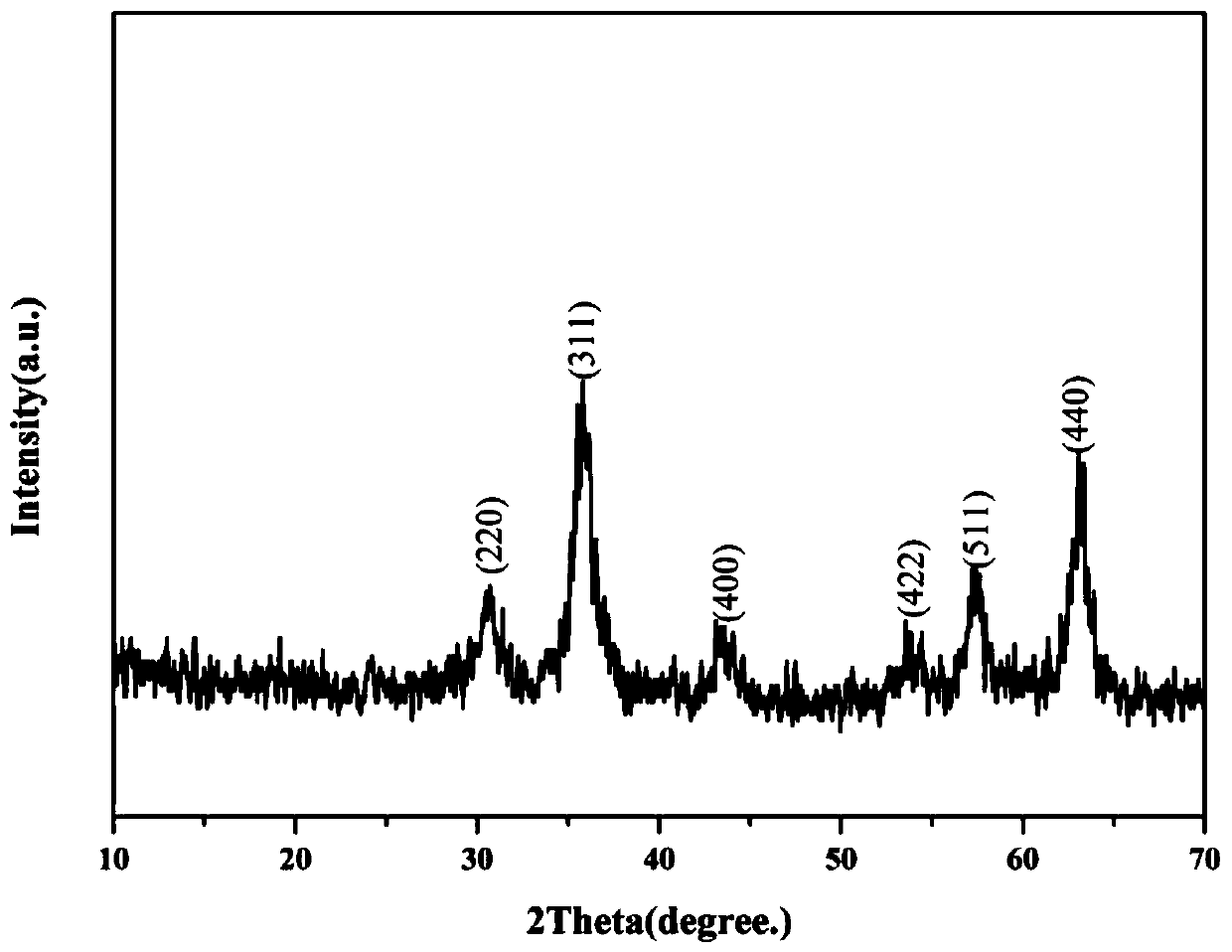

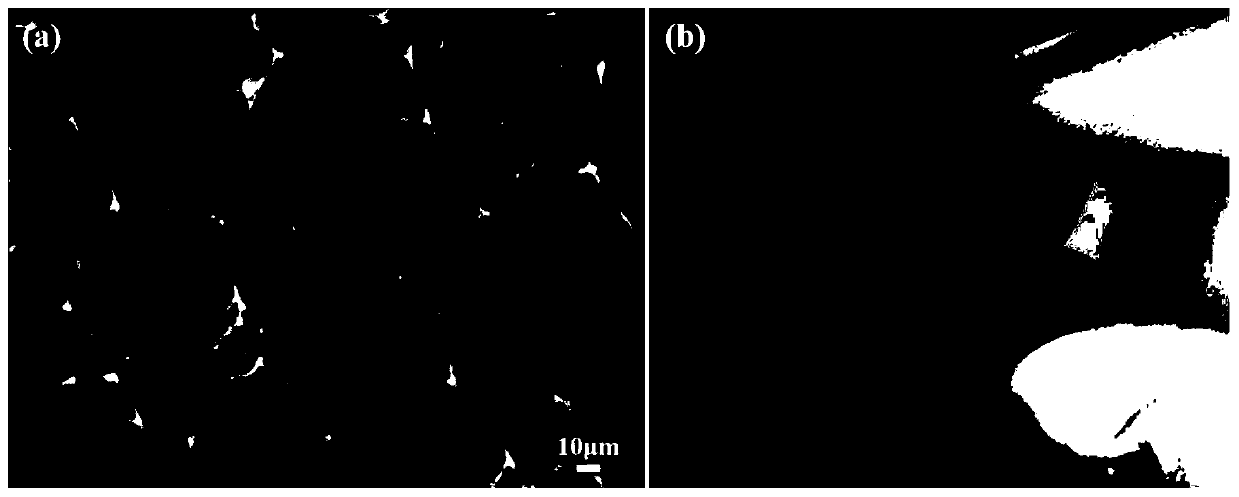

[0037] Step 3, configure Fe 3 o 4 Reaction solution of nanoparticles: Dissolve 2.3g of FeCl in 20ml of deionized water 3 ·6H 2 O and 1.2 g FeSO 4 ·7H 2 O, and add 0.3g surfactant PVP (polyvinylpyrrolidone), then magnetic stirring for 1 ~ 2h to obtain a uniform Fe 3 o 4 Reaction...

Embodiment 2

[0040] Step 1, pretreatment of melamine foam:

[0041] The melamine foam was ultrasonically cleaned with deionized water and absolute ethanol, respectively, for 30 minutes each, and then dried in an oven at a temperature of 90°C for 12 hours;

[0042] Step 2, place the pretreated melamine foam in step 1 in a tube furnace, 2 Multi-stage carbonization treatment is carried out under the protection of the atmosphere. The first stage is heated from room temperature to 200°C and kept for 1-2 hours; the second stage is heated to 400°C and kept for 1-2 hours; finally the temperature is raised to 850°C and kept for 1-2 hours. Finally, the cooling rate was controlled, and the sample was cooled to room temperature, and the heating rate and cooling rate were both 3°C / min to prepare foamed carbon;

[0043] Step 3, configure Fe 3 o 4 Reaction solution of nanoparticles: Dissolve 4.6g of FeCl in 40ml of deionized water 3 ·6H 2 O and 2.4 g FeSO 4 ·7H 2 O, and add 0.73g surfactant PVP (p...

Embodiment 3

[0047] Step 1, pretreatment of melamine foam:

[0048] The melamine foam was ultrasonically cleaned with deionized water and absolute ethanol, respectively, for 30 minutes each, and then dried in an oven at a temperature of 90°C for 12 hours;

[0049] Step 2, place the pretreated melamine foam in step 1 in a tube furnace, 2 Under the protection of the atmosphere, multi-stage carbonization treatment is carried out. The first stage is heated from room temperature to 200°C and kept for 1-2 hours; the second stage is heated to 400°C and kept for 1-2 hours; Control the cooling rate, cool the sample to room temperature, and the heating rate and cooling rate are both 4°C / min to prepare foamed carbon;

[0050] Step 3, configure Fe 3 o 4 Reaction solution of nanoparticles: Dissolve 6.9g of FeCl in 60ml deionized water 3 ·6H 2 O and 3.6 g FeSO 4 ·7H 2 O, and add 1.05g surfactant PVP (polyvinylpyrrolidone), then magnetically stir for 1-2h to get a uniform Fe 3 o 4 Reaction solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com