Technology for producing calcium superphosphate from titanium dioxide production byproduct waste acid

A technology of titanium dioxide and superphosphate, applied in the chemical industry, can solve the problems of waste of resources, high environmental protection cost, waste of calcium resources, etc., and achieve the effect of reducing the cost of concentration, avoiding the cost of pollution and treatment, and reducing the cost of treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

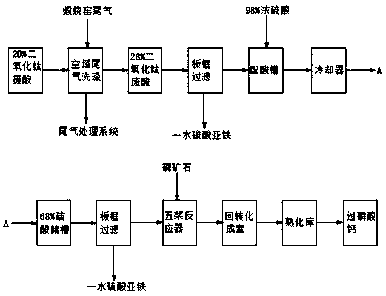

Method used

Image

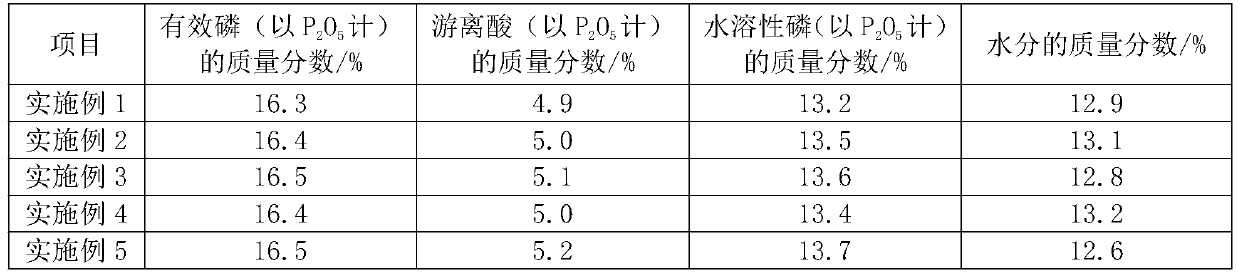

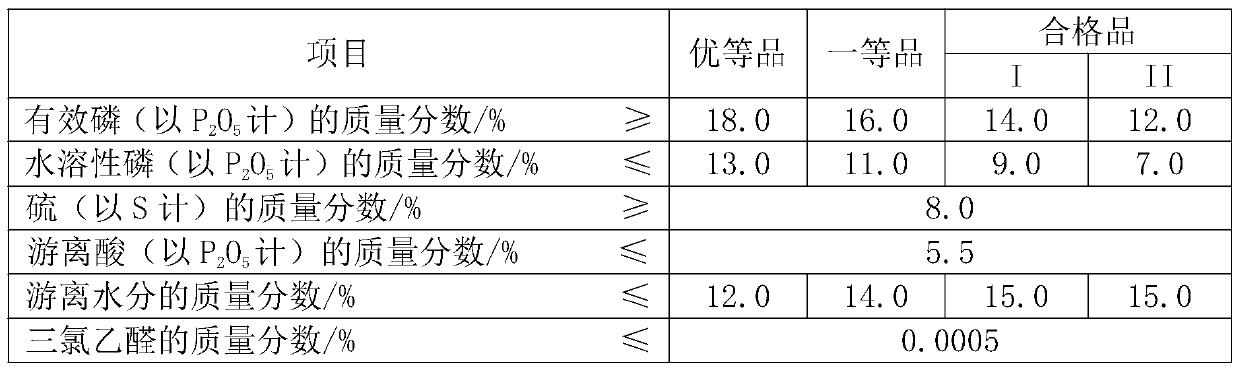

Examples

Embodiment 1

[0040] Embodiment 1, a kind of technique that utilizes titanium dioxide by-product waste acid to produce superphosphate, the concrete steps of this technique are as follows:

[0041] (1) Heat exchange the by-product waste acid in the production of titanium dioxide with the tail gas of the calcination rotary kiln in the empty tower, concentrate the waste acid to 28%, and then send it to a plate and frame filter press for coarse filtration to remove impurities to obtain clarified acid. The tail gas is sent to the tail gas treatment system for treatment and discharged up to standard;

[0042] (2) The clarified acid after coarse filtration is sent to the acid preparation section and mixed with 98% concentrated sulfuric acid in the acid preparation tank to increase the acid concentration to 65% to obtain concentrated acid;

[0043] (3) Cool the concentrated acid to <50°C through a graphite heat exchanger, then pump it to a plate and frame filter press for fine filtration, remove th...

Embodiment 2

[0045] Embodiment 2, a kind of technique that utilizes titanium dioxide by-product waste acid to produce superphosphate, the concrete steps of this technique are as follows:

[0046] (1) Heat exchange the by-product waste acid in the production of titanium dioxide with the tail gas of the calcination rotary kiln in the empty tower, concentrate the waste acid to 26%, and then send it to a plate and frame filter press for coarse filtration to remove impurities to obtain clarified acid. The tail gas is sent to the tail gas treatment system for treatment and discharged up to standard;

[0047] (2) The clarified acid after coarse filtration is sent to the acid preparation section and mixed with 97% concentrated sulfuric acid in the acid preparation tank to increase the acid concentration to 65% to obtain concentrated acid;

[0048] (3) Cool the concentrated acid to <50°C through a graphite heat exchanger, then pump it to a plate and frame filter press for fine filtration, remove th...

Embodiment 3

[0050] Embodiment 3, a kind of technique that utilizes titanium dioxide byproduct waste acid to produce superphosphate, the concrete steps of this technique are as follows:

[0051] (1) Heat exchange the by-product waste acid in the production of titanium dioxide with the tail gas of the calcination rotary kiln in the empty tower, concentrate the waste acid to 30%, and then send it to a plate and frame filter press for coarse filtration to remove impurities to obtain clarified acid. The tail gas is sent to the tail gas treatment system for treatment and discharged up to standard;

[0052] (2) The clarified acid after the coarse filtration is sent to the acid preparation section and mixed with 99% concentrated sulfuric acid in the acid preparation tank to increase the acid concentration to 67% to obtain concentrated acid;

[0053] (3) Cool the concentrated acid to <50°C through a graphite heat exchanger, then pump it to a plate and frame filter press for fine filtration, remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com