Preparation method for constant-temperature material

A technology of constant temperature and electric arc furnace, which is applied in the field of constant temperature materials, can solve the problems that pot materials do not have constant temperature requirements, are unstable, and the anti-dry function has not been well improved, and achieve outstanding application advantages, excellent thermal performance, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

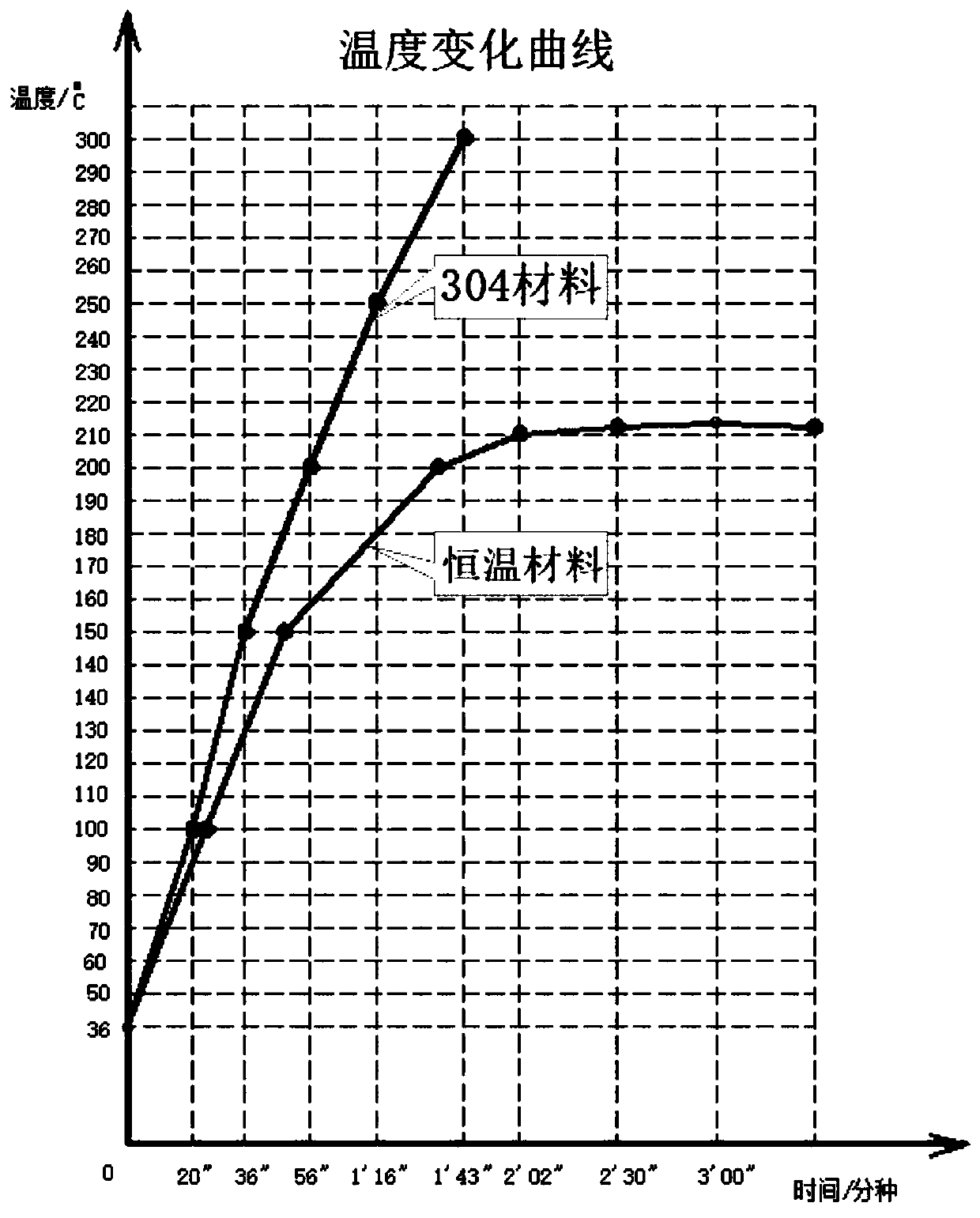

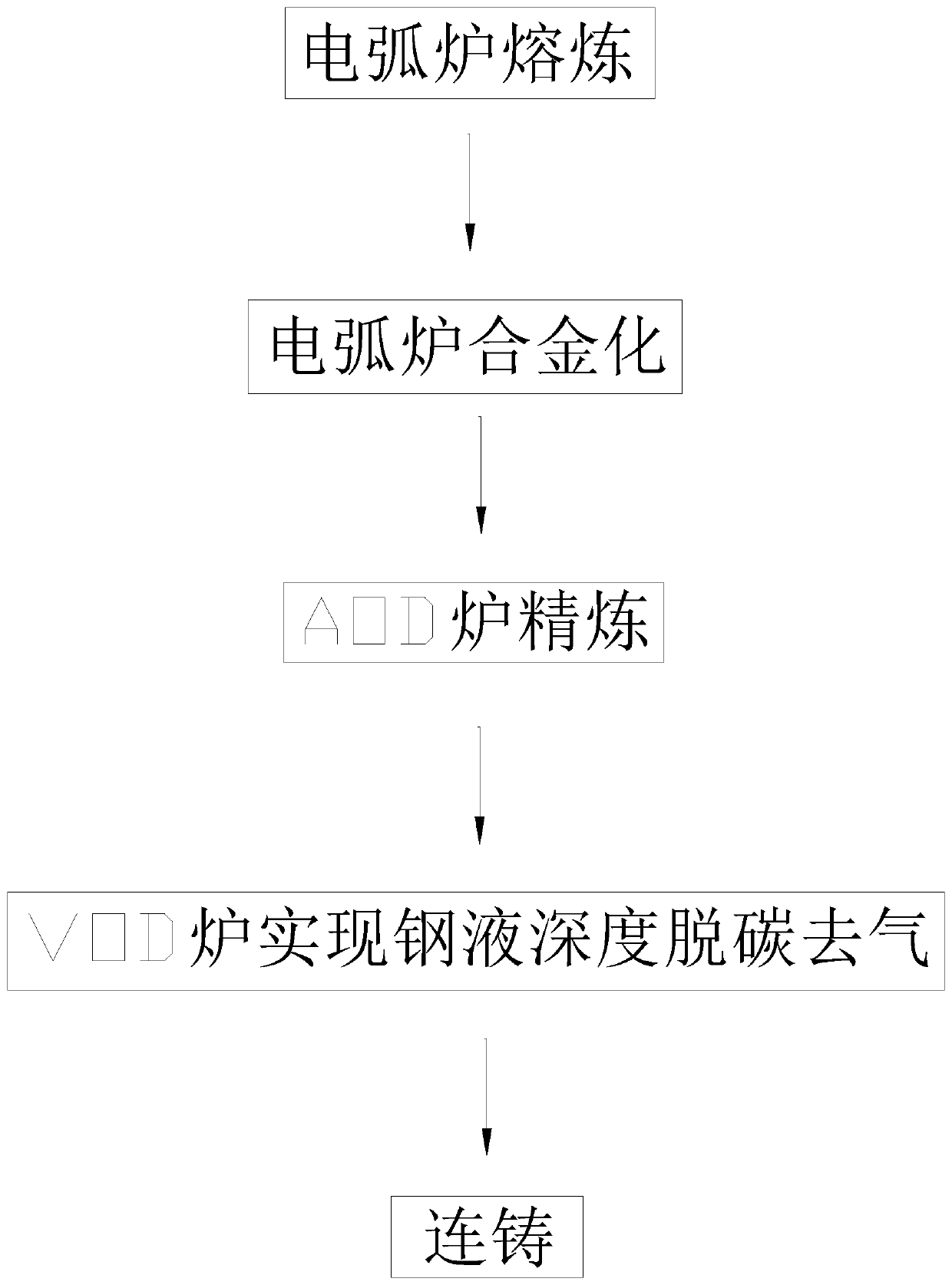

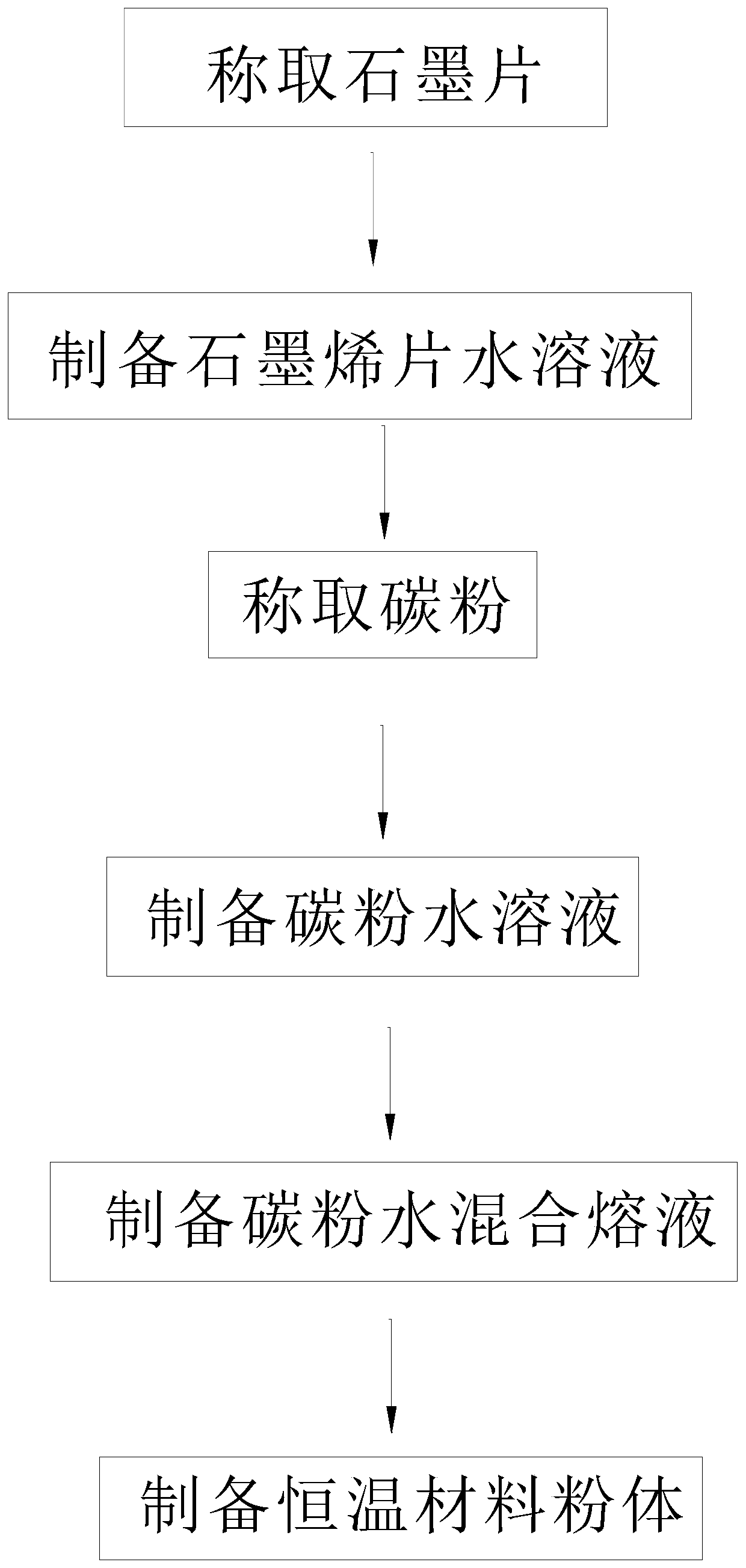

[0042] Such as Figure 1~4 As shown, this embodiment 1 discloses a preparation method of a constant temperature material, which includes the following steps:

[0043] Step 1, electric arc furnace smelting: direct reduced iron is used as the main raw material. The first electric arc furnace adopts an eccentric furnace bottom structure, and its main function is to melt direct reduced iron. The molten steel is dephosphorized, and the temperature of the molten pool reaches 1560 ° C ~ 1580 ° C;

[0044] Step 2, electric arc furnace alloying: the second electric arc furnace adopts a steel spout structure, and the electric furnace is smelted with oxygen blowing operation to remove part of the carbon in the molten steel, and the alloy of 60% to 70% by weight of stainless steel is added to the electric furnace to carry out The molten steel is alloyed, and the temperature of the molten pool reaches 1600 ° C ~ 1660 ° C;

[0045] Step 3, refining in AOD furnace: blending the molten stee...

Embodiment 2

[0089] In this embodiment 2, when the melt is mixed and stirred, a stirrer is used for stirring; the stirrer includes a frame 1 and a first container 2 arranged beside the frame 1; the top of the first container 2 is provided with an opening; The first container 2 is provided with a cavity communicating with the opening; the frame 1 is provided with a stirring device that can move up and down along the frame 1; the stirring device includes a stirring device for stirring the solution assembly, a driving device 3 for controlling the movement state of the stirring assembly, and a second container 4 for loading the melt to be mixed; the second container 4 communicates with the stirring assembly through a pipeline.

[0090] In this embodiment 2, in order to accurately adjust the height of the stirring device relative to the first container 2, so as to achieve the expected stirring effect, there is also a lifting device on the frame 1; the lifting device includes a vertically arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| smoke point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com