A cylindrical lithium-ion battery

A technology of lithium-ion batteries and cylinders, which is applied to battery electrodes, secondary batteries, battery pack components, etc., can solve problems such as serious low-temperature rate problems, complicated production processes, and unfriendly environments, and achieve improved electrochemical performance and cost-effectiveness. Effect of low film resistance and optimized coating surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment provides a cylindrical lithium-ion battery, including an electrode group, an electrolyte, a casing, a safety valve, and a cap, and the electrode group includes a positive pole piece, a negative pole piece, and an The separator, the positive pole piece contains lithium carbonate.

[0053] Preparation of positive electrode sheet:

[0054] The preparation method of the positive electrode sheet includes: adding 100 parts by weight of positive electrode active material LiNiCoMn, 1-3 parts by weight of binder PVDF, 0.5-3 parts by weight of carbon nanotubes, and 0.1-1 parts by weight of lithium carbonate to 40 parts by weight NMP, and then stirred in a vacuum mixer to form a stable and uniform dispersed positive electrode slurry. The working conditions of the vacuum mixer are: the temperature is controlled at 25°C, the stirring speed is controlled at 35rpm, the dispersion speed is controlled at 1500rpm, and the time is controlled at 150min.

[0055] Coat the o...

Embodiment 2

[0064] The difference between this embodiment and embodiment 1 is:

[0065] Electrolyte is made of solvent and lithium salt additive, and described solvent is the mixture of ethylene carbonate, methyl ethyl carbonate, diethyl carbonate and propylene carbonate by mass ratio 4:2:7:2, and described lithium salt Additives are LiODFB, LiPF 2 o 2 and LiTFSI in a mass ratio of 5:2:3, the mass ratio of the solvent and the lithium salt additive is 38:7.

[0066] The added amount of the electrolyte is 5g.

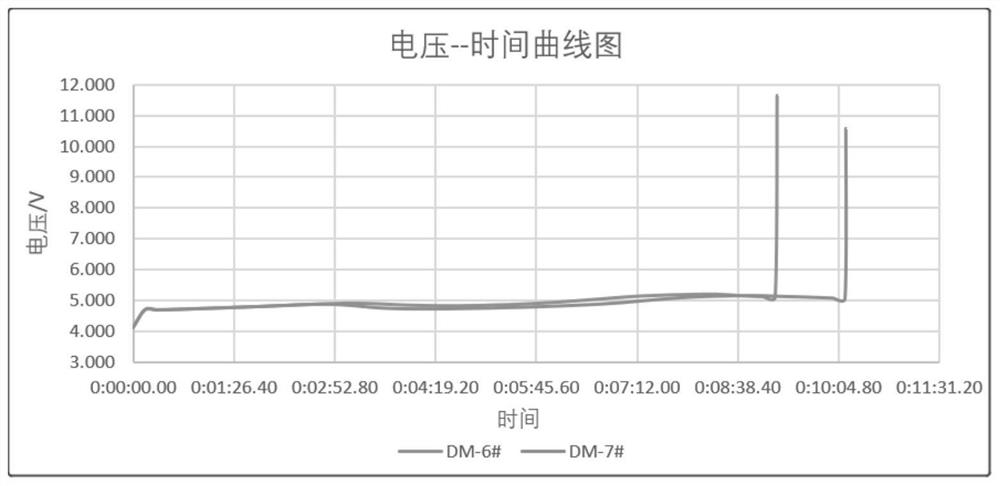

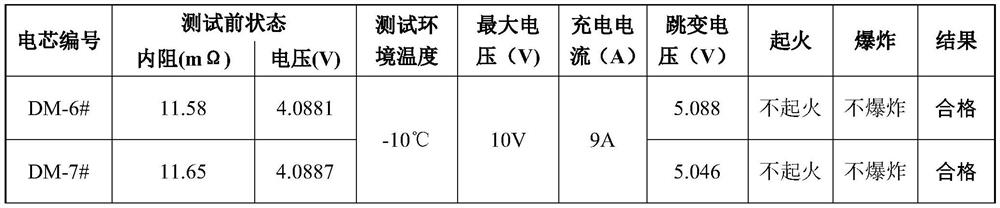

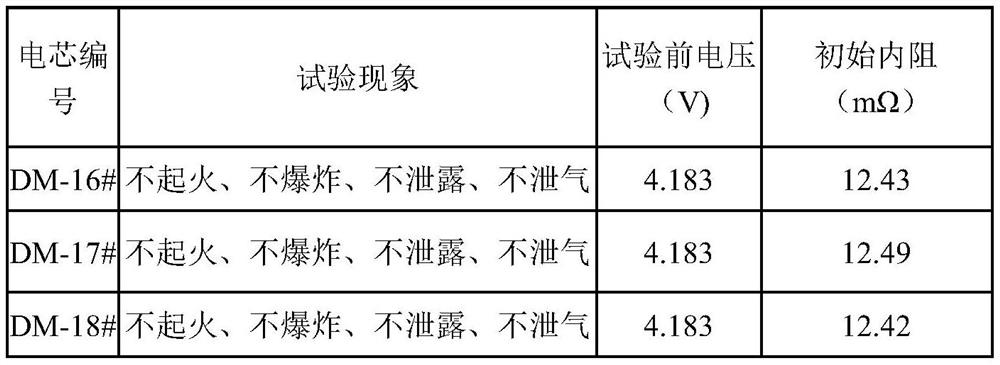

[0067] Test the cylindrical lithium-ion battery, the test conditions are: 3C charge 10C discharge cycle 10 times at -20°C, constant current and constant voltage to 4.2V, then put in the oven, and rise to 135±2 at a rate of 5°C / min After holding for 10 minutes at ℃, test the charge and discharge performance. The test results are shown in Table 2, where DM-16#, DM-17#, and DM-18# respectively represent three cylindrical lithium-ion batteries of the same batch.

[0068] Table 2

...

Embodiment 3

[0072] The difference between this embodiment and embodiment 1 is:

[0073] During the preparation of the positive electrode sheet, the positive electrode slurry is coated on both sides of the electrode sheet, and the surface density on both sides is 255g / m 2 ;

[0074] In the preparation process of the negative electrode sheet, the negative electrode slurry is coated on both sides of the electrode sheet, and the surface density of one side along the length direction is changed from 126g / m 2 Gradient to 114g / m 2 , the areal density of the other side along the same direction by 114g / m 2 Gradient to 126g / m 2 , and ensure that the sum of the surface densities on both sides corresponding to each position of the negative pole piece in the entire length direction is a fixed value of 240g / m 2 .

[0075] The obtained cylindrical lithium-ion battery was tested under the same conditions as in Example 1 and Example 2, and it also had excellent low-temperature rate performance, safet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com