Composite microsphere and preparation method thereof

A composite microsphere and microsphere technology, applied in the field of solar cells, can solve the problems of limited amount of dissolved or deposited silver, reduced solar cell performance, low surface excess free energy, etc. rate, improve the effect of printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

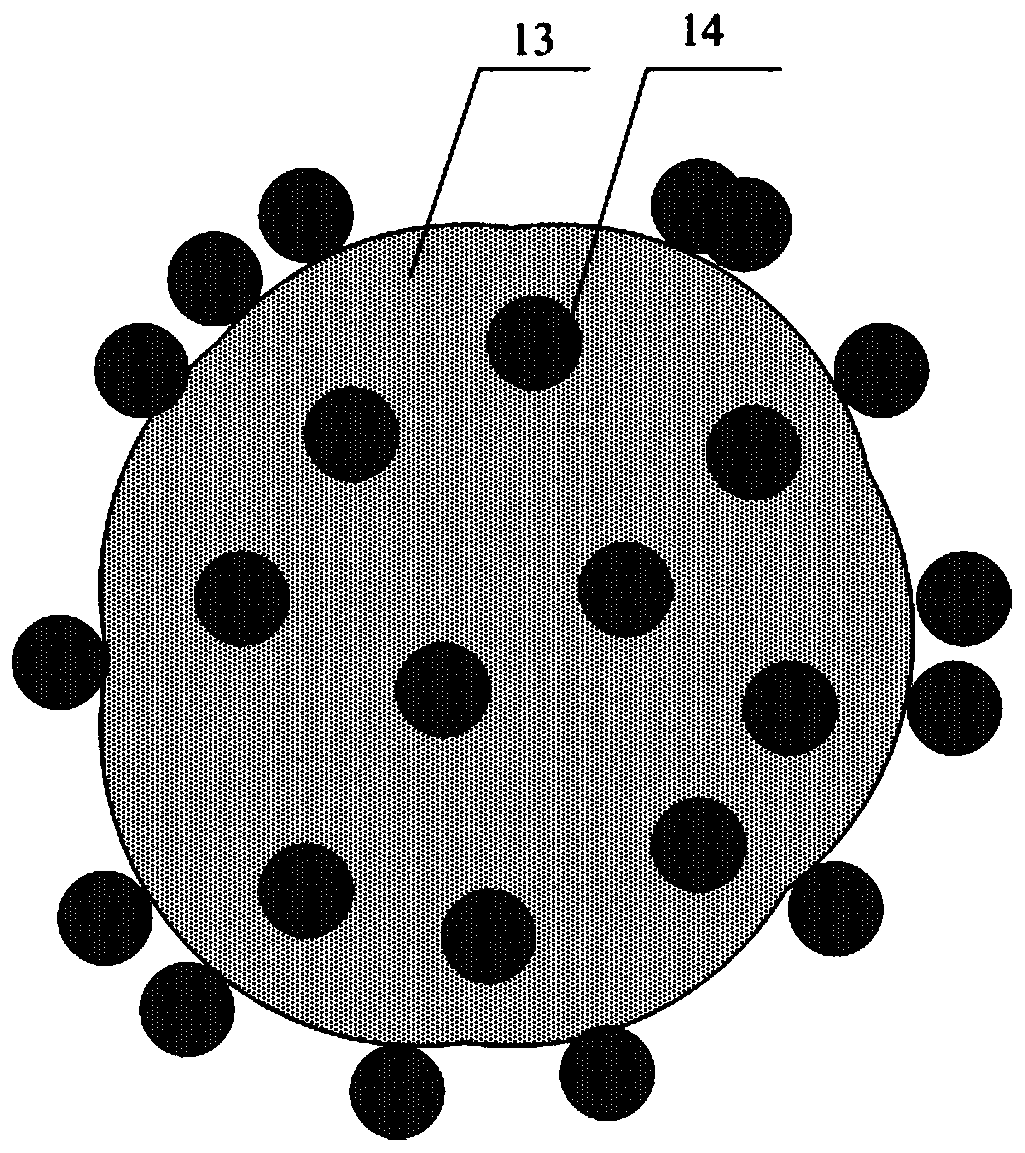

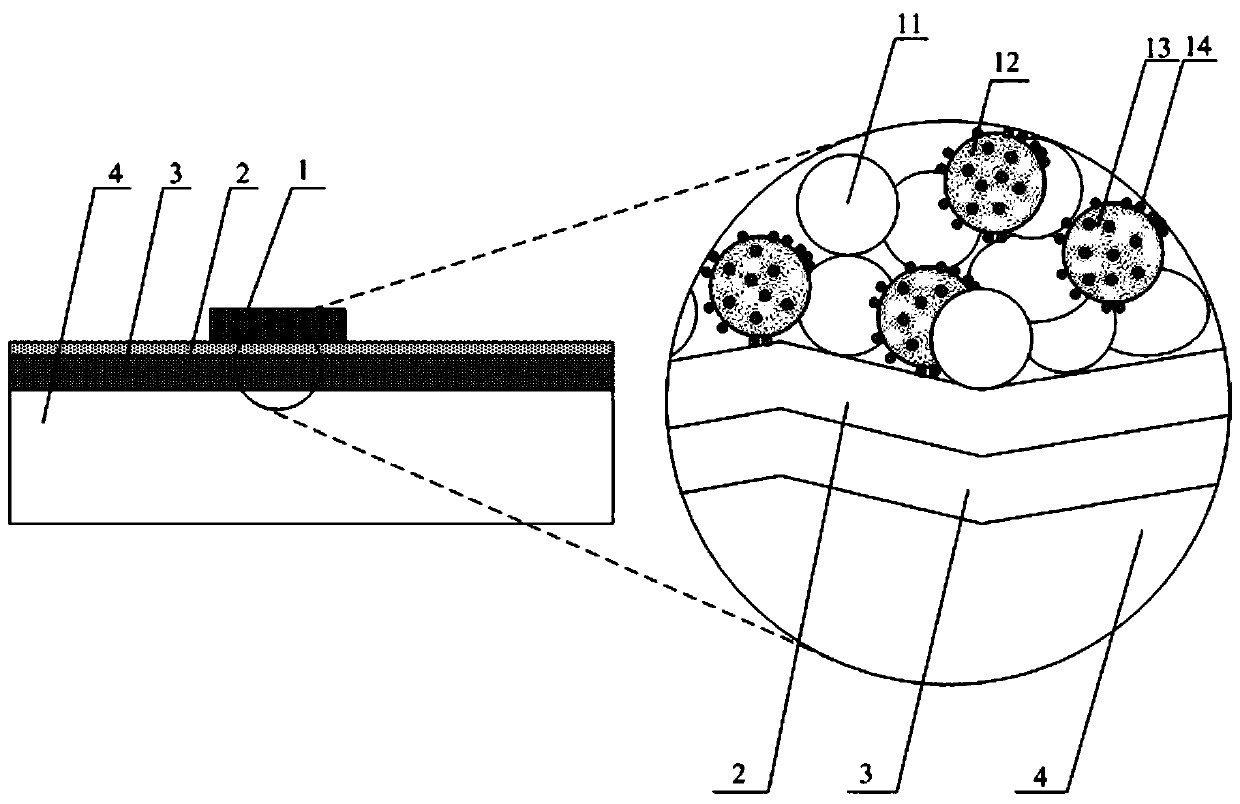

[0020] This embodiment provides a composite microsphere, which includes silver particles and polymer microspheres; the particle size of the silver particles is between 1 nm and 200 nm.

[0021] The silver particles are randomly implanted inside the polymer microspheres or adsorbed on the outer surface of the polymer microspheres.

Embodiment 2

[0024] The present embodiment provides a kind of preparation method of composite microsphere, comprises the steps:

[0025] S21 is used to prepare the step of the polymer microsphere that comprises vinyl macromer;

[0026] S22 for combining polymer microspheres with AgNO 3 The solutions are mixed to form the first mixed solution, thereby reacting to prepare polymer microspheres loaded with a large amount of silver ions;

[0027] S23 is a step of adding a reducing agent into the first mixed liquid to reduce silver ions to silver particles, thereby reacting to prepare composite microspheres containing silver particles.

[0028] Further, the reducing agent is potassium borohydride;

[0029] Further, the mass ratio of the silver particles to the polymer microspheres is between 1:100 and 1:1;

[0030] Further, in the preparation method provided in this example, during the preparation process, by adjusting the added AgNO 3 concentration to adjust the particle size of the silver ...

Embodiment 3

[0035] The present embodiment provides a kind of preparation method of composite microsphere, comprises the steps:

[0036] S31 is a step for preparing polymer microspheres comprising vinyl macromers;

[0037] S32 is used to disperse 10g dry polymer microspheres in water and add 1.575g AgNO 3 thereby forming the step of the second mixture;

[0038] S33 is used to put the second mixture in N 2 The step of fully stirring for 12 hours in a protected environment to fully disperse and adsorb the silver ions in the polymer microspheres;

[0039]S34 is a step for mixing 0.1 mol / L KOH aqueous solution with the second mixture so as to adjust the pH value of the second mixture to between 8 and 9 and continue stirring for 0.5 hours to 1 hour;

[0040] S35 is a step for adding 100 mL of D-glucose solution dropwise to the second mixture, stirring for 6-12 hours to make it fully react, thereby obtaining the second mixture;

[0041] S36 is a step of transferring the second mixture to a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com