Composite modified biochar preparation method

A technology of composite modification and biochar, applied in the direction of alkali metal compounds, chemical instruments and methods, water pollutants, etc., can solve problems such as self-purification, strong toxicity of cadmium, threat to human health and safety, etc., to achieve abundant quantity and types, improving adsorption efficiency, and expanding the effect of pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

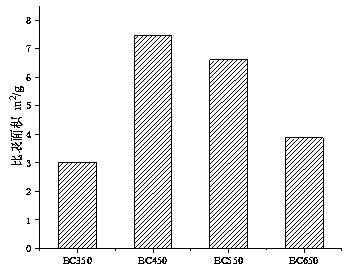

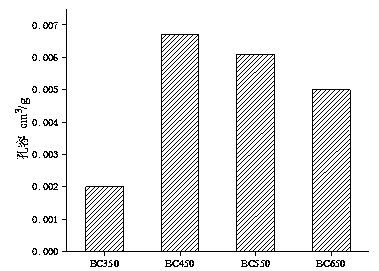

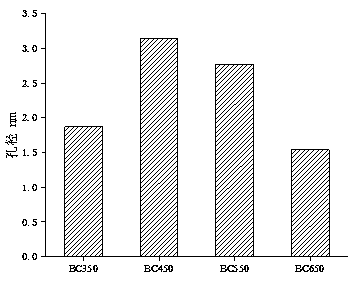

[0037] Effect of different carbonization temperatures on biochar adsorption.

[0038] (1) Preparation of wheat straw biochar: Wheat straw was air-dried for 1 week and crushed through a 0.85mm sieve. The crushed wheat straw was placed in a crucible and compacted slightly. Then the crucible was placed in a muffle furnace, and the carbonization temperature was set to 350, 450, 550, 650 。 C, the heating rate is 12 。 C / min, carbonize for 3h, take it out after natural cooling to room temperature, wash with 1mol / L HCl, filter and wash with distilled water until neutral, at 75 。 C under the condition of drying to constant weight, wheat straw biochar can be obtained;

[0039] (2) Ash content: Take 1g of biochar passed through a 0.25mm sieve and spread it on the bottom of the crucible. 。 C for 4h, after cooling to room temperature, calculate the ash content of biochar by weight loss;

[0040] (3) BET method to calculate specific surface area, BJH method to calculate average pore dia...

experiment example 2

[0044] Effect of different concentrations of KOH modification on biochar adsorption.

[0045] (1) Preparation of wheat straw biochar: Wheat straw was air-dried for 2 weeks and crushed through a 0.85 mm sieve. The crushed wheat straw was placed in a crucible and lightly compacted. Then the crucible was placed in a muffle furnace and the temperature was adjusted to 450 °C. 。 C, the heating rate is 10 。 C / min, carbonize for 4h, take it out after natural cooling to room temperature, wash with 0.5mol / L HCl, filter and wash with distilled water until neutral, at 80 。 C under the condition of drying to constant weight, wheat straw biochar can be obtained;

[0046] (2) Preparation of KOH modified biochar: impregnate the original biochar prepared in the above step (2) in KOH solution, set the concentration of KOH solution to 0.1, 0.5, 1, 2, 3mol / L, and the solid-liquid ratio according to 1:20 (g / ml), 100 。 Heating and stirring at C for 2 hours, cooling naturally after heating, filte...

Embodiment 3

[0050] A preparation method of composite modified biochar, comprising the following steps:

[0051] (1) Preparation of wheat straw biochar: Wheat straw was air-dried for 3 weeks and crushed through a 0.85 mm sieve. The crushed wheat straw was placed in a crucible and lightly compacted. Then the crucible was placed in a muffle furnace and the temperature was adjusted to 450 °C. 。 C, the heating rate is 8 。 C / min, carbonize for 5h, take it out after natural cooling to room temperature, wash with 0.1mol / L HCl, filter and wash with distilled water until neutral, at 85 。 C under the condition of drying to constant weight, wheat straw biochar can be obtained;

[0052] (2) Preparation of KOH modified biochar: impregnate the original biochar prepared in the above step (1) in 2mol / L KOH solution, the solid-liquid ratio is 1:15 (g / ml), 105 。 Heating and stirring at C for 4 hours, cooling naturally after heating, filtering, washing with distilled water repeatedly until the pH remained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com