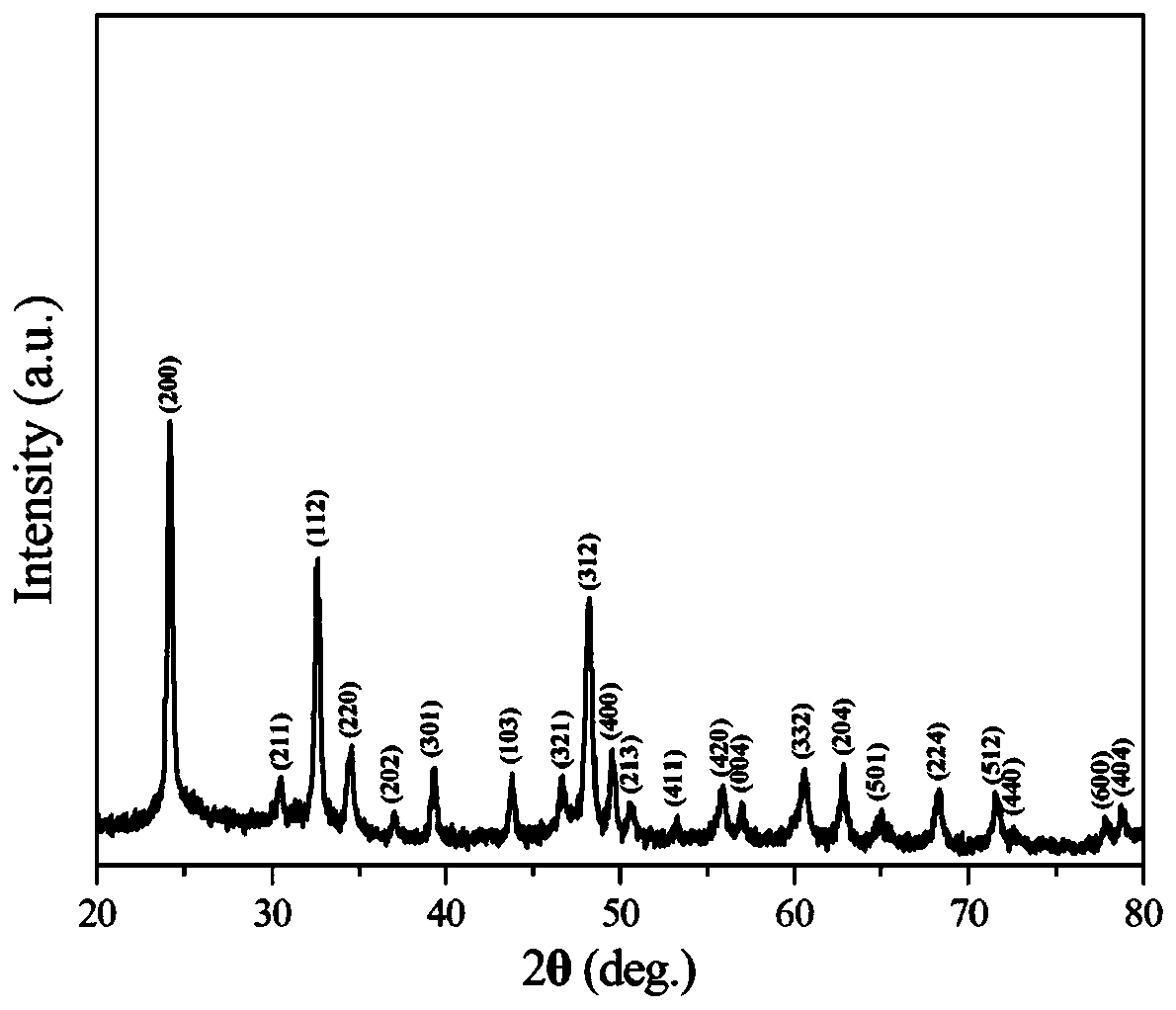

Praseodymium vanadate nanowire electrode material and preparation method thereof

An electrode material and nanowire technology, which is applied in the field of praseodymium vanadate nanowire electrode material and its preparation, has good application prospects, easy control, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: first fix the copper sheet in the middle of the reaction vessel, then mix praseodymium chloride and sodium vanadate, which account for 35% of the water weight, with water and place in the reaction vessel and seal it, wherein the molar ratio of praseodymium chloride and sodium vanadate The ratio is 1:1, the total amount of praseodymium chloride, sodium vanadate and water accounts for 70% of the filling degree of the reaction vessel, and the copper sheet with gray deposits on the surface is obtained by microwave heating at a temperature of 450°C and holding for 3 hours.

[0025] Step 2: First mix praseodymium chloride and sodium vanadate evenly, wherein the molar ratio of praseodymium chloride and sodium vanadate is 1:1, and then place the mixed powder of praseodymium chloride and sodium vanadate in a high-temperature atmosphere furnace for reaction In the container, place the copper sheet containing gray deposits on the surface obtained in step 1 in the water-cool...

Embodiment 2

[0027] Step 1: first fix the copper sheet in the middle of the reaction vessel, then mix praseodymium chloride and sodium vanadate accounting for 20% of the water weight with water and place in the reaction vessel and seal it, wherein the molar ratio of praseodymium chloride and sodium vanadate The ratio is 1:1, the total amount of praseodymium chloride, sodium vanadate and water accounts for 40% of the filling degree of the reaction vessel, and the copper sheet with gray deposits on the surface is obtained by microwave heating at a temperature of 400°C and holding for 2 hours.

[0028] Step 2: First mix praseodymium chloride and sodium vanadate evenly, wherein the molar ratio of praseodymium chloride and sodium vanadate is 1:1, and then place the mixed powder of praseodymium chloride and sodium vanadate in a high-temperature atmosphere furnace for reaction In the container, place the copper sheet containing gray deposits on the surface obtained in step 1 in the water-cooled lo...

Embodiment 3

[0030] Step 1: first fix the copper sheet in the middle of the reaction vessel, then mix praseodymium chloride and sodium vanadate, which account for 22% of the water weight, with water and place in the reaction vessel and seal it, wherein the molar ratio of praseodymium chloride and sodium vanadate The ratio is 1:1, the total amount of praseodymium chloride, sodium vanadate and water accounts for 45% of the filling degree of the reaction vessel, and the copper sheet with gray deposits on the surface is obtained by heating at a temperature of 410 °C for 2.2 hours by microwave .

[0031] Step 2: First mix praseodymium chloride and sodium vanadate evenly, wherein the molar ratio of praseodymium chloride and sodium vanadate is 1:1, and then place the mixed powder of praseodymium chloride and sodium vanadate in a high-temperature atmosphere furnace for reaction In the container, place the copper sheet containing gray deposits on the surface obtained in step 1 in the water-cooled l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com