Holocellulos composite aerogel and preparation method thereof

A composite airgel and whole cellulose technology, which is applied in the field of full cellulose composite airgel and its preparation, can solve the problems of high density, easy shrinkage, and low specific surface area of cellulose-based airgel, and achieve wide application Foreground, stable properties, effect of huge specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

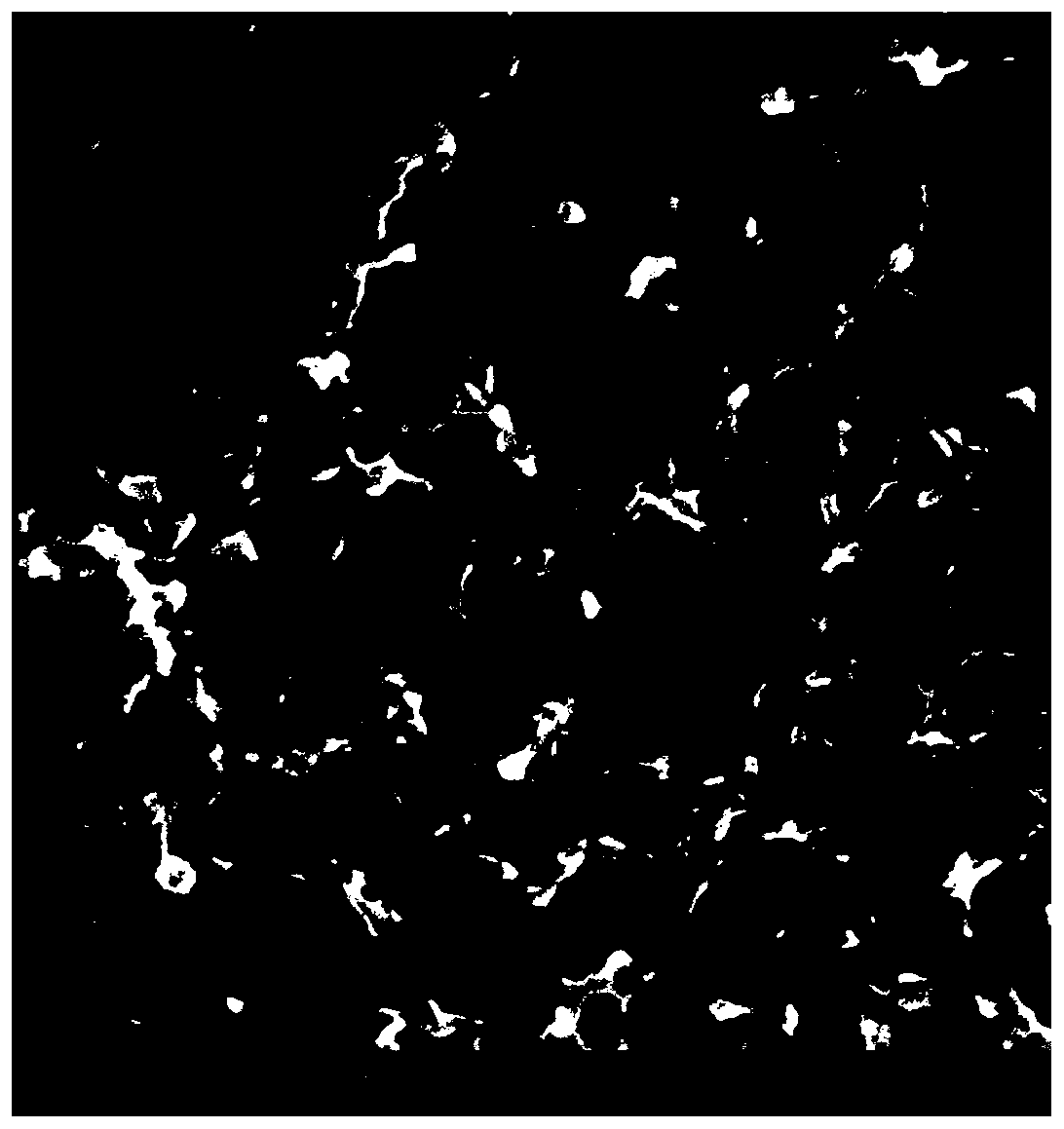

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 full cellulose composite airgel:

[0027] (1) Pour the ionic liquid into a round-bottomed flask, spin-evaporate at 60°C for 1 hour, put it in a vacuum drying oven, and dry it at 85°C for 1 day.

[0028] (2) Crush the cellulose with a pulverizer and pass it through a 200-mesh sieve to obtain cellulose raw material powder. The cellulose nanofibril water suspension is centrifuged, the water in the upper layer is removed, washed with dimethyl sulfoxide, and the obtained cellulose nanofibril is dispersed in dimethyl sulfoxide for subsequent use (cellulose nanofibril and di The mass ratio of methyl sulfoxide is 1:2).

[0029] (3) add 3wt% vacuum-dried cellulose powder in ionic liquid 1-allyl-3-methylimidazolium chloride, add dimethyl sulfoxide (the mass ratio of dimethyl sulfoxide and ionic liquid 1 :4), the oil bath was heated to 105° C. and magnetically stirred until the cellulose was completely dissolved.

[0030] (4) The solvent system t...

Embodiment 2

[0032] The preparation of embodiment 2 full cellulose composite airgel:

[0033] (1) Pour the ionic liquid into a round-bottomed flask, spin-evaporate at 60°C for 1 hour, put it in a vacuum drying oven, and dry it at 85°C for 1 day.

[0034] (2) Crush the cellulose with a pulverizer and pass it through a 200-mesh sieve to obtain cellulose raw material powder. The cellulose nanofibril water suspension is centrifuged, the water in the upper layer is removed, washed with dimethyl sulfoxide, and the obtained cellulose nanofibril is dispersed in dimethyl sulfoxide for subsequent use (cellulose nanofibril and di The mass ratio of methyl sulfoxide is 1:2).

[0035] (3) add 3wt% vacuum-dried cellulose powder in ionic liquid 1-butyl-3-methylimidazolium chloride, add dimethyl sulfoxide simultaneously (the mass ratio of dimethyl sulfoxide and ionic liquid is 1: 4), the oil bath was heated to 105°C and magnetically stirred until the cellulose was completely dissolved.

[0036] (4) The ...

Embodiment 3

[0038] The preparation of embodiment 3 full cellulose composite airgel:

[0039] (1) Pour the ionic liquid into a round-bottomed flask, spin-evaporate at 60°C for 1 hour, put it in a vacuum drying oven, and dry it at 85°C for 1 day.

[0040] (2) Crush the cellulose with a pulverizer and pass it through a 200-mesh sieve to obtain cellulose raw material powder. Centrifuge the aqueous suspension of cellulose nanofibrils, remove the water in the upper layer, wash with N,N-dimethylformamide, and disperse the obtained cellulose nanofibrils in N,N-dimethylformamide for later use (The mass ratio of cellulose nanofibrils to N,N-dimethylformamide is 1:5).

[0041](3) Add 3wt% vacuum-dried cellulose powder to the ionic liquid 1-allyl-3-methylimidazolium chloride, and simultaneously add N,N-dimethylformamide (N,N-dimethylformamide The mass ratio of amide to ionic liquid is 1:4), the oil bath is heated to 105°C and magnetically stirred until the cellulose is completely dissolved.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com