Spraying-free high-gloss plastic for household appliances and preparation method of plastic

A spray-free, high-gloss technology, applied in the field of modified plastics, can solve the problems of poor gloss, poor adhesion, poor adhesion of spray coatings, etc., and achieve the effects of high gloss, good pearlescent property, and good whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

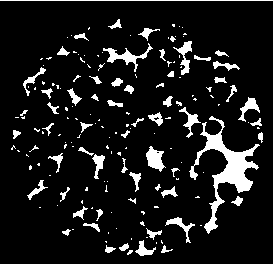

Image

Examples

Embodiment 1

[0036] (1) Fully grind the mica powder and glass powder in a ball mill to obtain composite pearl powder; the ball-to-material ratio of the ball mill is 6:1, the cylinder rotation speed is 260r / min, and the grinding time is 8h;

[0037] The proportion of each raw material is, in parts by weight, 50 parts by weight of mica powder and 50 parts by weight of glass powder;

[0038] (2) First disperse the composite pearl powder and tetrabutyl titanate obtained in step (1) in water, then add organic acid to adjust the pH to 5, and then stir at high speed to form a composite wet gel; the organic acid is citric acid;

[0039] The ratio of each raw material is, in parts by weight, 25 parts by weight of composite pearl powder, 5 parts by weight of tetrabutyl titanate, and 70 parts by weight of water;

[0040] (3) First add the porous inorganic microspheres to the composite wet gel prepared in step (2), vacuum-treat for 18 minutes, wrap the composite wet gel on the pore structure and surface of the...

Embodiment 2

[0045] (1) Fully grind the mica powder and glass powder in a ball mill to obtain composite pearl powder; the ball-to-material ratio of the ball mill is 4:1, the cylinder rotation speed is 240r / min, and the grinding time is 12h;

[0046] The proportion of each raw material is, in parts by weight, 40 parts by weight of mica powder and 60 parts by weight of glass powder;

[0047] (2) First disperse the composite pearl powder and tetrabutyl titanate obtained in step (1) in water, then add organic acid to adjust the pH to 5, and then stir at high speed to form a composite wet gel; the organic acid is sulfamic acid;

[0048] The ratio of each raw material is, in parts by weight, 30 parts by weight of composite pearl powder, 10 parts by weight of tetrabutyl titanate, and 60 parts by weight of water;

[0049] (3) First add the porous inorganic microspheres to the composite wet gel prepared in step (2), vacuum-treat for 10 minutes, wrap the composite wet gel on the pore structure and surface of...

Embodiment 3

[0054] (1) Fully grind the mica powder and glass powder in a ball mill to obtain composite pearl powder; the ball-to-material ratio of the ball mill is 5:1, the cylinder speed is 200r / min, and the grinding time is 6h;

[0055] The proportion of each raw material is, in parts by weight, 42 parts by weight of mica powder and 58 parts by weight of glass powder;

[0056] (2) First disperse the composite pearl powder and tetrabutyl titanate obtained in step (1) in water, then add organic acid to adjust the pH to 5, and then stir at high speed to form a composite wet gel; the organic acids are citric acid and ethyl acetate. Diaminetetraacetic acid;

[0057] The ratio of each raw material is, in parts by weight, 22 parts by weight of composite pearl powder, 8 parts by weight of tetrabutyl titanate, and 70 parts by weight of water;

[0058] (3) First add the porous inorganic microspheres to the composite wet gel prepared in step (2), vacuum-treat for 15 minutes, wrap the composite wet gel on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com