Parachute fixing disc material and preparation method thereof

A fixed disc and parachute technology, applied in the field of materials, can solve the problems of unqualified wear resistance of the fixed disc, poor dimensional stability, easy deformation of the fixed disc, etc., to meet the requirements of ultra-low temperature testing and use, high dimensional stability, and increase product size. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

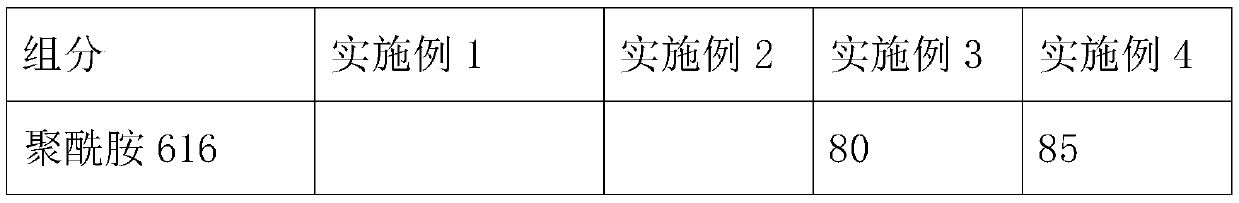

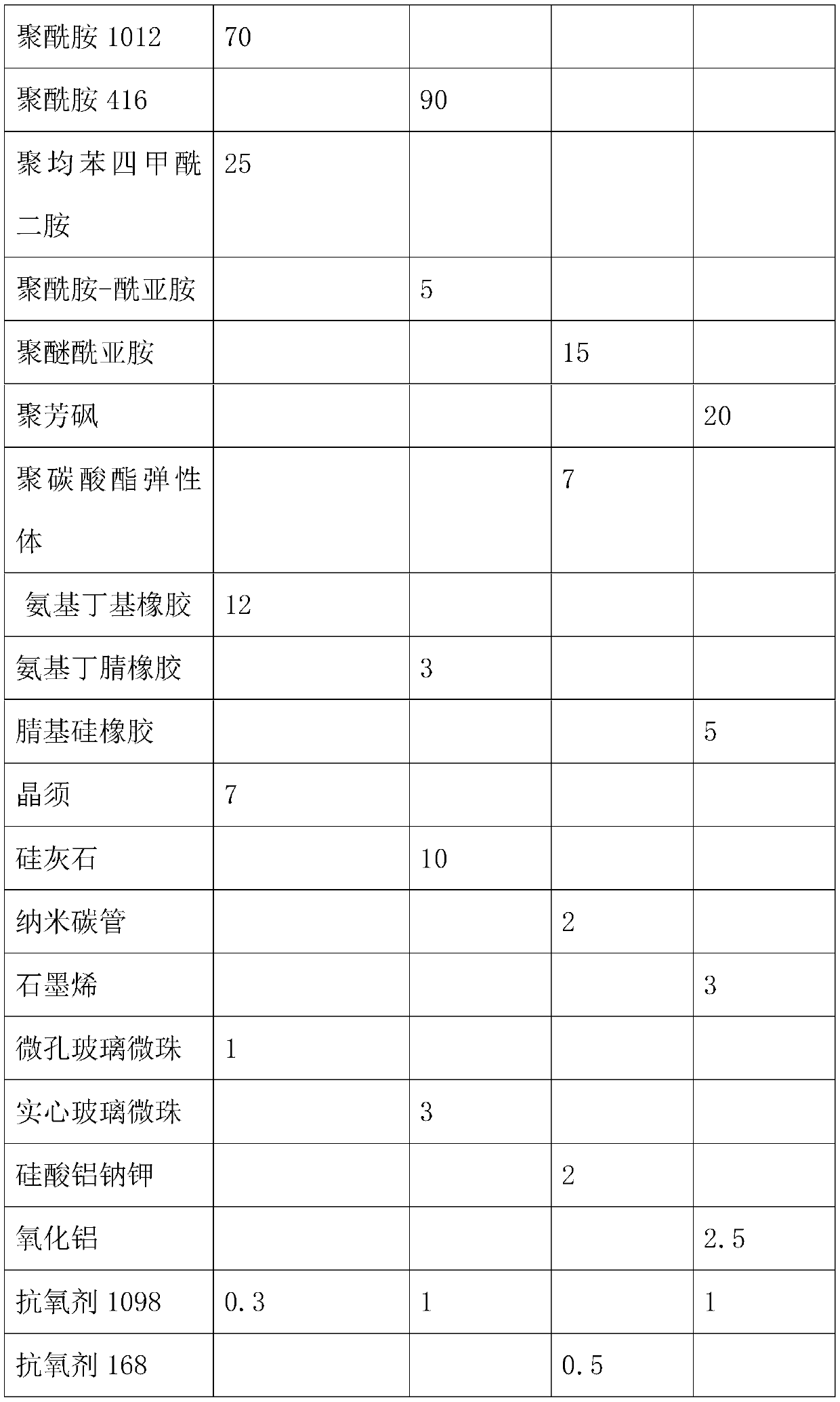

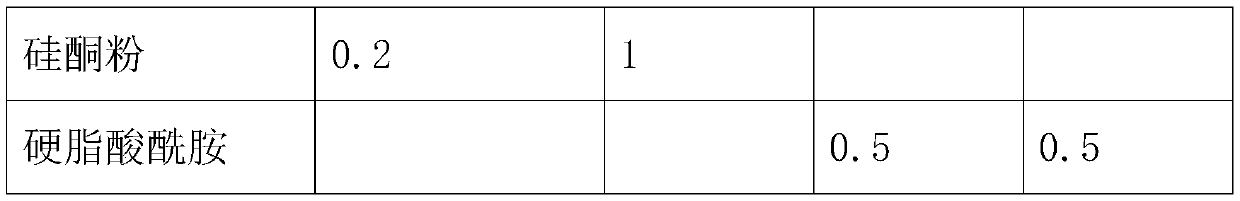

[0031] 1. 70 parts of polyamide is polyamide 1012, the alloy component is 25 parts of polypyromellitic diamide, the toughening agent is 12 parts of aminobutyl rubber, and the wear-resistant additive is 1 part of microporous glass beads , 0.5 parts of other additives (0.3 parts of antioxidant 1098 and 0.2 parts of silicone powder) were added into the mixer and pre-mixed for 1-3 minutes to obtain a mixture.

[0032] 2. Add the mixture obtained in the above step (1) into the twin-screw extruder through the hopper, and accurately weigh 7 parts of the reinforcing agent as whiskers through a weight loss scale and introduce it into the extruder through a side feeder. Compounding, mixing, extruding, drawing, air-drying, and granulation to obtain polyamide composite materials that can be used for parachute fixed disks; wherein, the temperature of the extruder is set to a zone to the head: 250-330°C.

[0033] 3. Pass the mixture obtained in the step (2) through an injection molding mach...

Embodiment 2

[0036] 1. 90 parts of polyamide is polyamide 416, the alloy component is 5 parts of polyamide-imide, the toughening agent is 3 parts of amino-butadiene rubber, the wear-resistant additive is 3 parts of solid glass beads, and other additives Add 2 parts of antioxidant (1 part of antioxidant 1098 and 1 part of silicone powder) into the mixer, and pre-mix for 1-3 minutes to obtain a mixture.

[0037] 2. Add the mixture obtained in the above step (1) into the twin-screw extruder through the hopper, and accurately weigh 10 parts of wollastonite as the reinforcing agent through a weight loss scale and introduce it into the extruder through a side feeder. Plasticizing, mixing, extruding, drawing, air-drying, and granulating to obtain a polyamide composite material that can be used for parachute fixed disks; wherein, the temperature of the extruder is set at the first zone to the head: 250-330°C.

[0038] 3. Pass the mixture obtained in the step (2) through an injection molding machin...

Embodiment 3

[0041] 1. 80 parts of polyamide is polyamide 616, the alloy component is 15 parts of polyetherimide, the toughening agent is 7 parts of polycarbonate elastomer, the wear-resistant additive is 2 parts of sodium potassium aluminum silicate, and other Add 1 part of auxiliary agent (0.5 part of antioxidant 168 and 0.5 part of stearic acid amide) into the mixer, and pre-mix for 1-3 minutes to obtain a mixture.

[0042] 2. Add the mixture obtained in the above step (1) into the twin-screw extruder through the hopper, and accurately weigh 2 parts of carbon nanotubes as the reinforcing agent through a weight loss scale and introduce it into the extruder through a side feeder. Plasticizing, mixing, extruding, drawing, air-drying, and granulating to obtain a polyamide composite material that can be used for parachute fixed disks; wherein, the temperature of the extruder is set at the first zone to the head: 250-330°C.

[0043] 3. Pass the mixture obtained in the step (2) through an inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com