Yellow feather broiler feed containing lysine residue and preparation method of yellow feather broiler feed

A yellow-feather broiler and feed technology, which is applied in the field of yellow-feather broiler feed and its preparation, can solve the problems of nutritional requirements, raw material utilization efficiency, anti-nutritional factor tolerance, etc., to reduce production costs, ensure growth performance, and reduce use volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

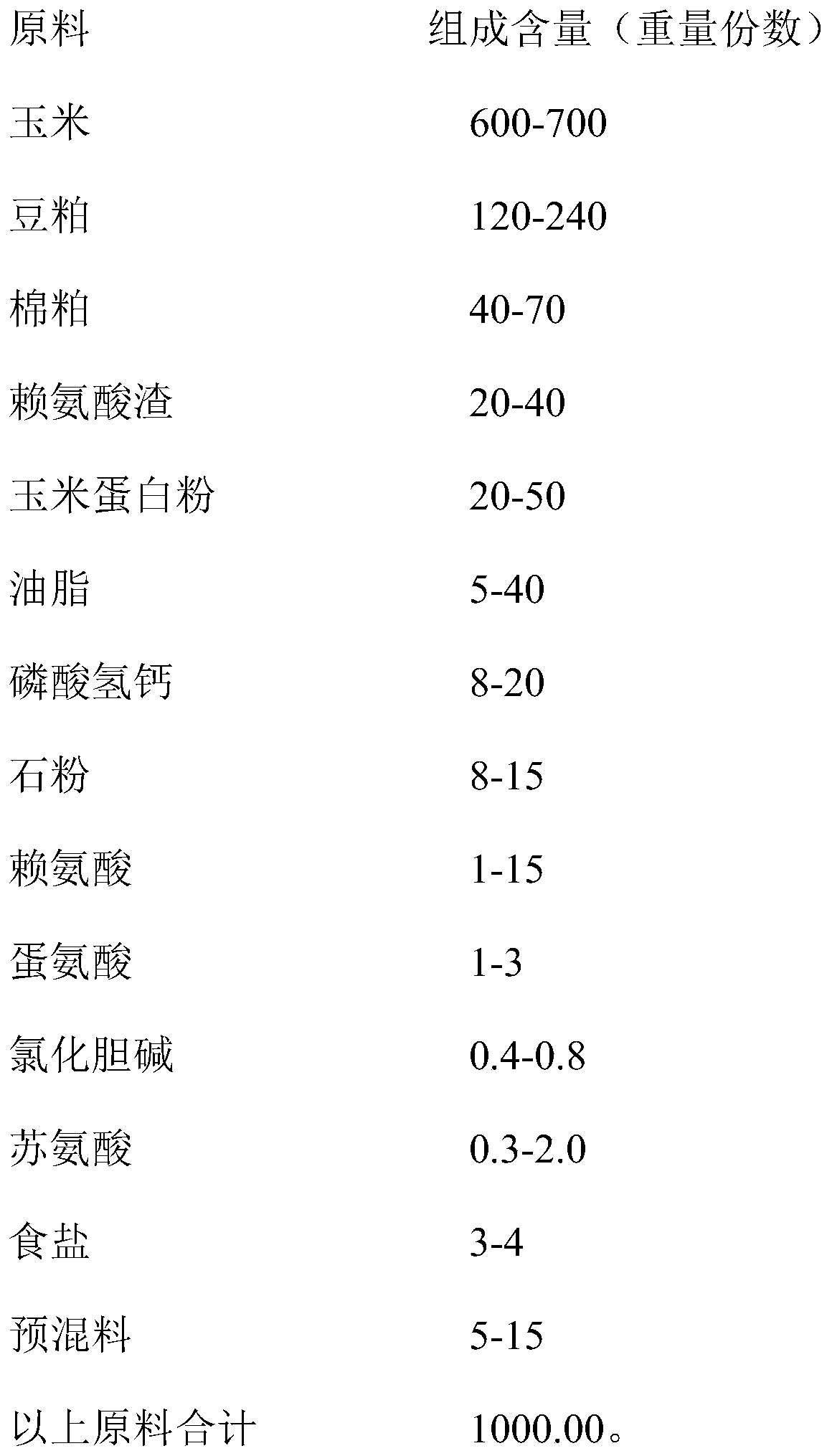

[0031] Example 1: In order to verify the technical effect of the present invention, the following diet formula is adopted to test, as shown in Table 1:

[0032] Table 1 (kg)

[0033] project control group Test group 1 Test group 2 Feed number A1 B1 C1 corn 637.5 659.8 675.0 soybean meal 231.7 177.7 141.3 Cotton meal 40.0 40.0 40.0 corn protein flour 40.0 40.0 40.0 grease 9.2 7.4 6.1 stone powder 13.7 13.9 14.0 Calcium hydrogen phosphate 12.5 13.0 13.3 Lysine 5.0 7.1 8.6 Premix 4.0 4.0 4.0 Sodium chloride 3.5 3.5 3.6 Methionine 1.8 2.2 2.4 threonine 0.3 0.6 0.9 Choline chloride 0.8 0.8 0.8 Lysine residue 30.0 50.0

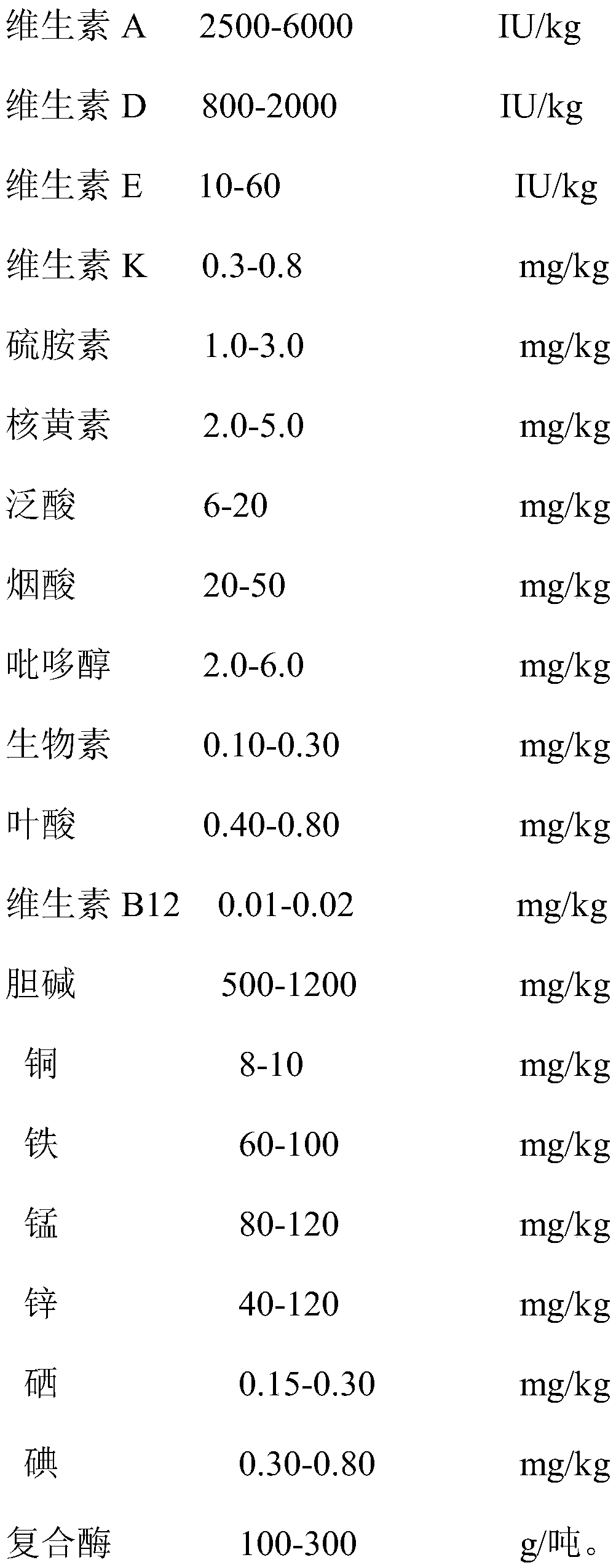

[0034] The composition and content of the premix vitamin A 2500IU / kg; vitamin D 800IU / kg; vitamin E 10IU / kg; vitamin K 0.3mg / kg; thiamine 1.0mg / kg; riboflavin 2.0mg / kg; pantothenic acid 6mg Niacin 20mg / kg; Pyridoxine 2.0mg / kg; B...

example 2

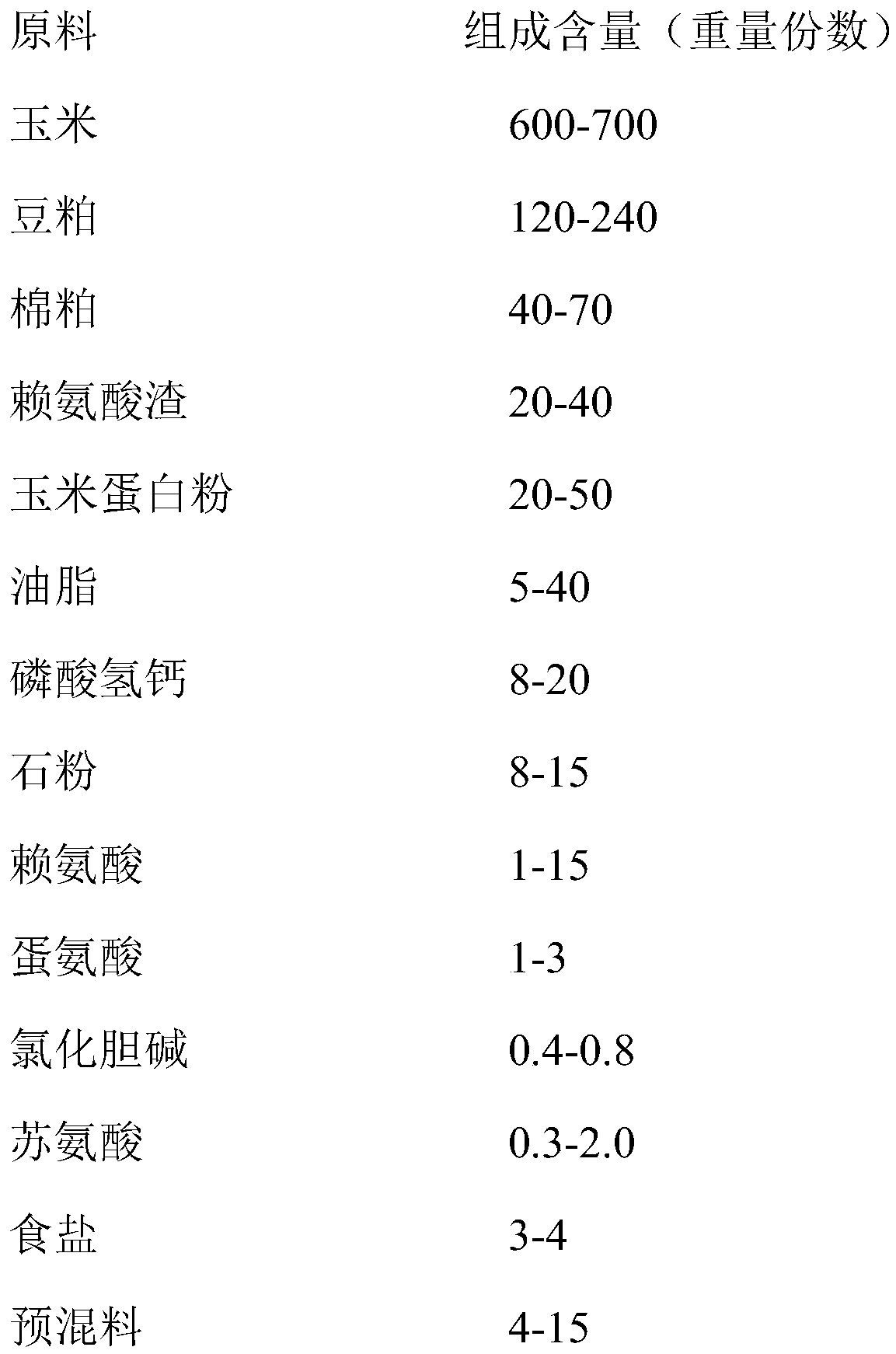

[0046] Example 2: In order to verify the technical effect of the present invention, the following diet formula is adopted to test, as shown in Table 3 below:

[0047] Table 3 (kg)

[0048]

[0049] Wherein the composition and content of the premix are as in the formula described in Example 1 above.

[0050] The preparation method of the above-mentioned table 1 yellow feather broiler feed is completed according to the following process steps:

[0051] A, after the raw material of described parts by weight is removed impurity, with the pulverizer of 3.0mm sieve, corn, soybean meal, cotton meal, corn gluten powder are respectively pulverized to powder;

[0052] B. Put the pulverized raw materials in A into a mixer for mixing and stirring evenly, then mix the lysine, methionine, threonine, sodium bicarbonate, salt, premix, stone powder, hydrogen phosphate Calcium is put in together through the small material inlet of the mixer, and then mixed evenly;

[0053]C, the uniformly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com