Two-component polyurethane finish paint and preparation method thereof

A two-component polyurethane and polyurethane dispersion technology, applied in the field of coatings, can solve the problems of unsatisfactory paint film performance and slow crosslinking speed, and achieve the effects of low cost, improved water resistance, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

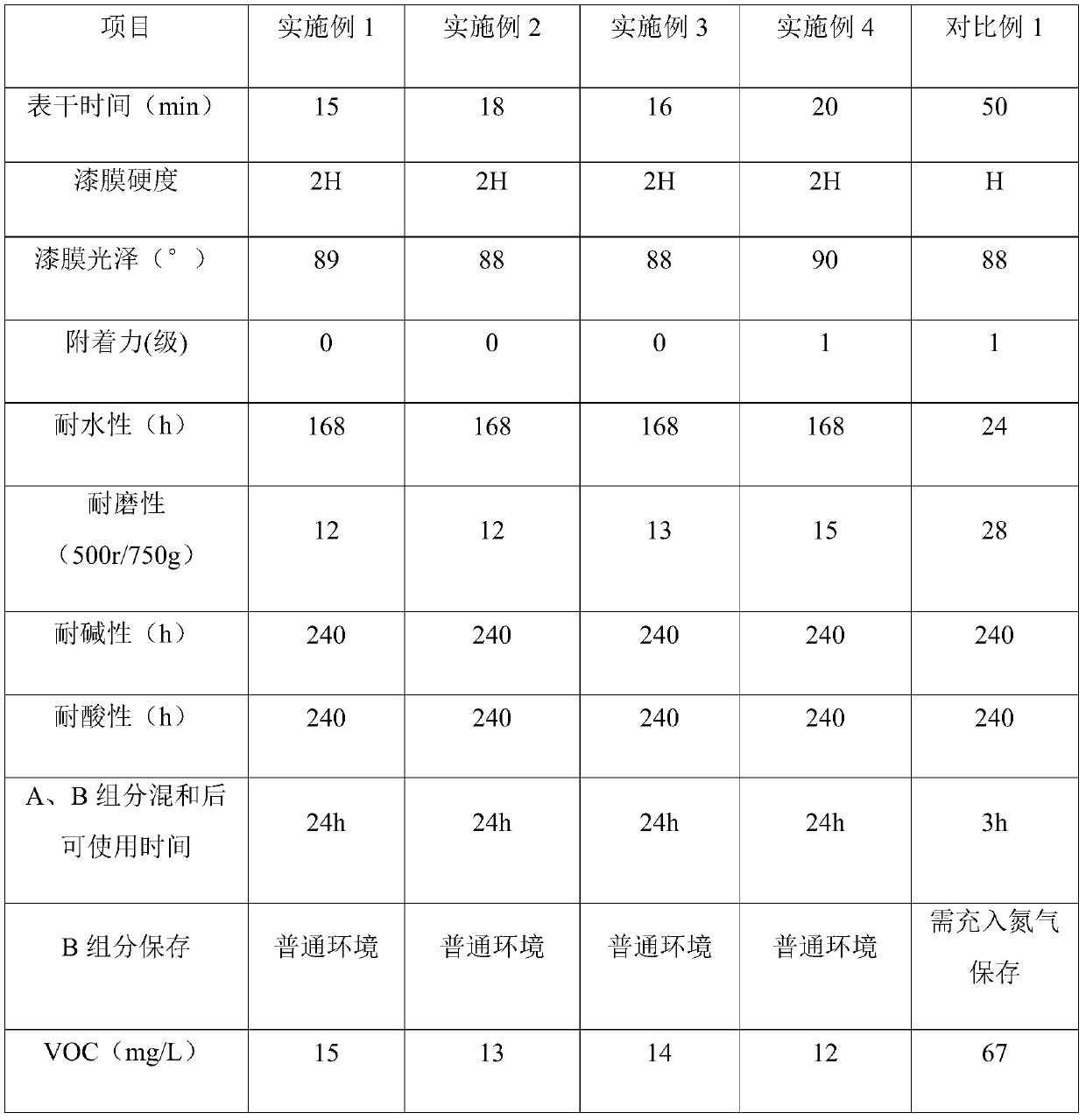

Examples

Embodiment 1

[0039] The embodiment of the present invention provides a two-component polyurethane topcoat, including A component and B component, and the A component includes the following raw material components in mass percentage: 35% of water-based hydroxyl acrylic dispersion, water-based self-crosslinking polyurethane Dispersion 20%, casein emulsion 5%, wetting and dispersing agent 0.5%, defoamer 0.1%, pigment 23%, leveling agent 0.7%, substrate wetting agent 0.2%, thickener 0.5% and deionization water 15%;

[0040] The B component includes the following raw material components in mass percentage: water-based polycarbodiimide curing agent;

[0041] The mass ratio of the A component and the B component is 10:1.

[0042] Wherein, the aqueous hydroxyl acrylic dispersion is a mixture of Setaqua 6522 and Bayhydrol2469 in a mass ratio of 0.8:1; the self-crosslinking polyurethane dispersion is Bayhydrol XP 2593 and Bayhydrol XP in a mass ratio of 1:1 2558; the casein emulsion is PB-403 of H...

Embodiment 2

[0048] The embodiment of the present invention provides a two-component polyurethane topcoat, including A component and B component, and the A component includes the following raw material components in mass percentage: 45% of low water-based hydroxyl acrylic dispersion, water-based self-crosslinking Polyurethane dispersion 15%, casein emulsion 9.1%, wetting and dispersing agent 1.5%, defoamer 0.1%, pigment 15%, leveling agent 1%, substrate wetting agent 0.1%, thickener 0.2% and Ionized water 13%;

[0049] The B component includes the following raw material components in mass percentage: water-based polycarbodiimide curing agent;

[0050] The mass ratio of the A component and the B component is 15:1.

[0051] The trade mark of above-mentioned each component is identical with embodiment 1, and difference is: described aqueous hydroxyl acrylic dispersion is the mixture of Setaqua 6522 and Bayhydrol 2469 that mass ratio is 1.2:1; Described self-crosslinking polyurethane dispersi...

Embodiment 3

[0054] The embodiment of the present invention provides a two-component polyurethane topcoat, including A component and B component, and the A component includes the following raw material components in mass percentages: 50% water-based hydroxyl acrylic dispersion, water-based self-crosslinking polyurethane Dispersion 5%, casein emulsion 15%, wetting and dispersing agent 1%, defoamer 0.5%, pigment 17.6%, leveling agent 0.5%, substrate wetting agent 0.3%, thickener 0.1% and deionization water 10%;

[0055] The B component includes the following raw material components in mass percentage: water-based polycarbodiimide curing agent;

[0056] The mass ratio of the A component to the B component is 20:1.

[0057] The trade mark of above-mentioned each component is identical with embodiment 1, and difference is: described aqueous hydroxyl acrylic dispersion is the mixture of Setaqua 6522 and Bayhydrol 2469 that mass ratio is 1:1; Described self-crosslinking polyurethane dispersion i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com