Manufacturing method of front windshield automobile coated glass

A manufacturing method and technology of coated glass, applied in glass manufacturing equipment, windshield, glass molding, etc., can solve the problems of affecting the signal, and the nano-silver layer is easily corroded and oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The transparent glass with a thickness of 2.0mm is cut, edged, edged, cleaned and dried in sequence to obtain the original glass of the car;

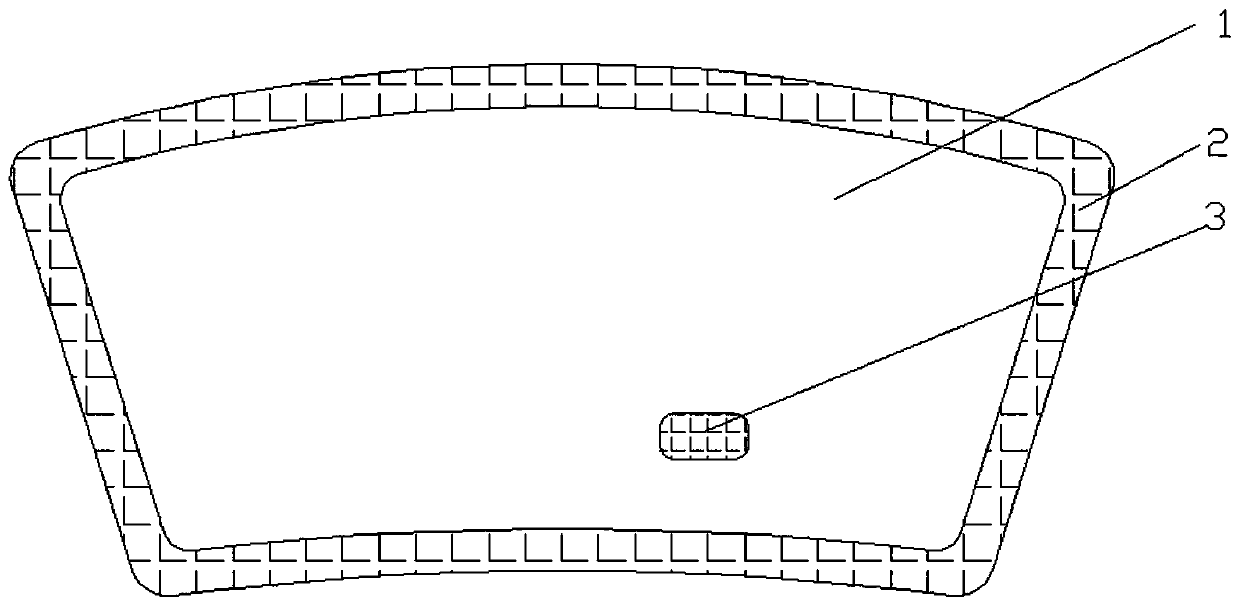

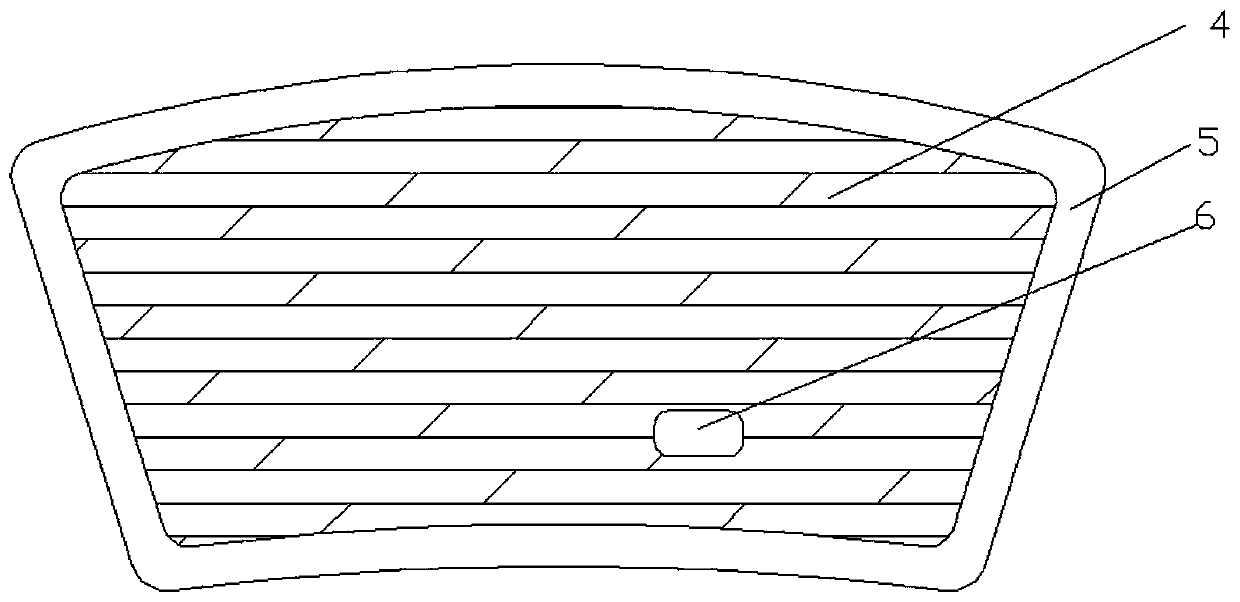

[0045] The original sheet glass of the automobile is divided into a coating area, a communication window area (a side length is a square of 140mm) and an edge sealing area (a width of 15mm);

[0046] By screen printing, high temperature silicone oil (kinematic viscosity is 320mm 2 / s; the relative density is 1.08; the flash point is 280°C) coated on the communication window area and the edge banding area to obtain a high-temperature silicone oil layer (3 μm);

[0047] By magnetron sputtering, a low-radiation film is coated on the surface of the original automobile glass coated with high-temperature silicone oil: the first dielectric layer (Si 3 N 4 Thin film, thickness is 24nm), first growth layer (Al, H co-doped AZO:H transparent conductive oxide film, Al content is 3wt%; Ar and H in the sputtering atmosphere 2 The volume flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com