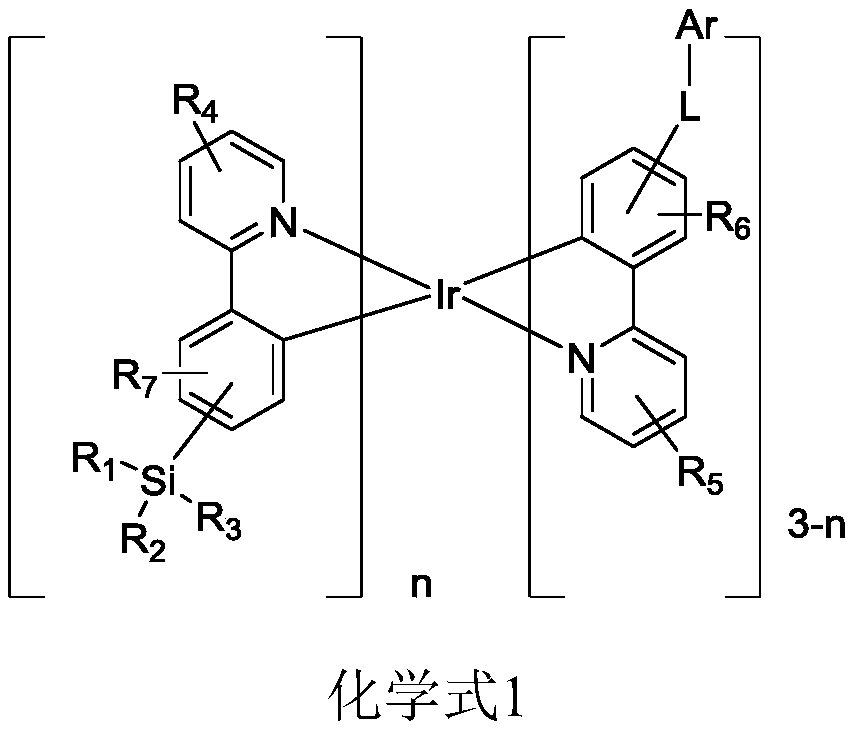

Phosphorescent material, preparation method thereof and organic electroluminescent device containing phosphorescent material

A phosphorescent material, C6-C60 technology, applied in the field of organic light-emitting materials, can solve the problems of high synthesis price of phosphorescent materials, high synthesis process requirements, easy to pollute the environment, etc., to achieve improved luminous efficiency, improved efficiency and life, and easy access to raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

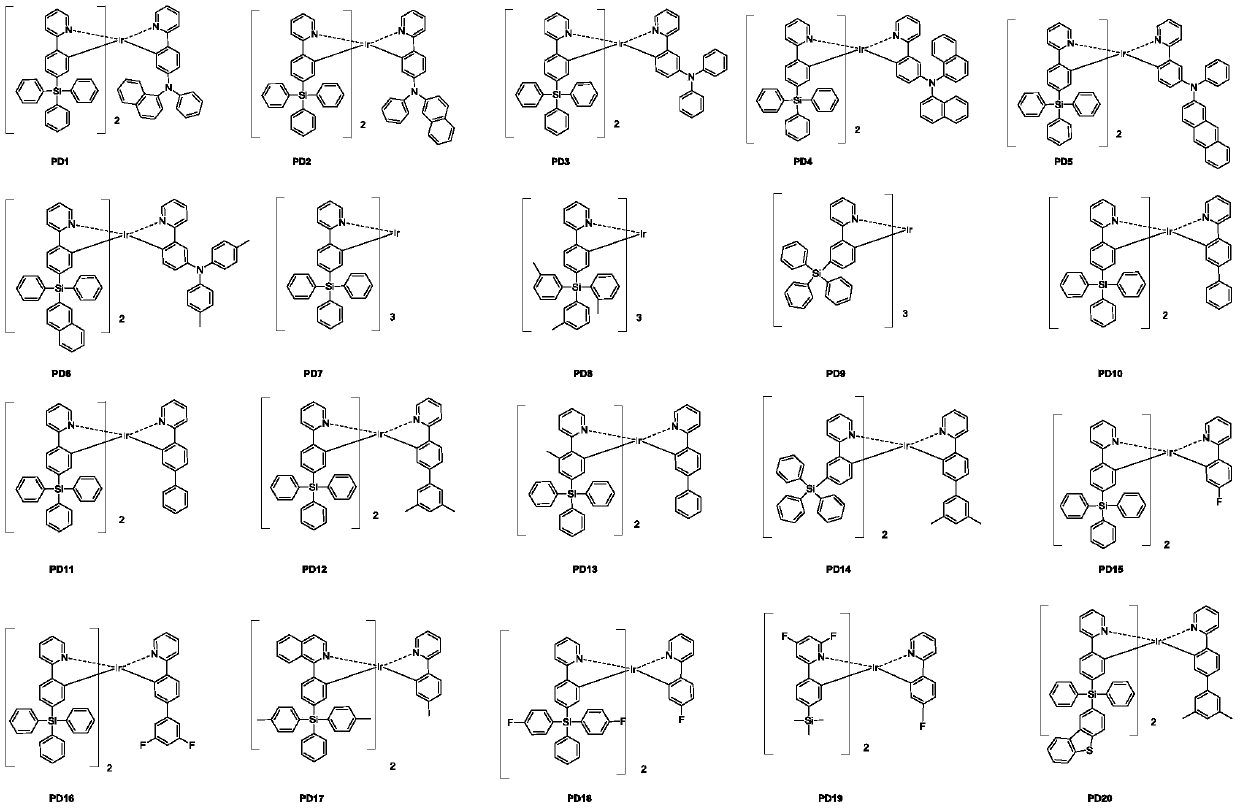

[0046] Example 1: Compound PD10

[0047]

[0048] Synthesis of intermediate 10-3

[0049]

[0050] Accurately weigh 20 grams (67.8 mmol) of triphenylchlorosilane and add it to the reaction flask, 300 mL of toluene, 150 mL of ethanol, 150 mL of deionized water, nitrogen protection, and stir for 30 minutes, then add the raw material 2-phenylpyridine (4 - boric acid) 16.2 g (81.4 mmol) and catalyst Pd (PPh 3 ) 40.6 g (0.678 mol), potassium carbonate 18.57 g (134.6 mmol), heated to 90 ° C for 24 hours.

[0051] Post-treatment process: TLC monitoring until the reaction is complete. The temperature was lowered, the liquid was separated at rest, and the water layer was separated to keep the toluene layer. Add another 150 mL of water to wash the toluene layer once, separate the layers, dry the toluene layer, spin dry the toluene to obtain a dark solid. After passing through a silica gel column, first use dichloromethane: petroleum ether = 1:4 about 500mL to wash out the imp...

Embodiment 2

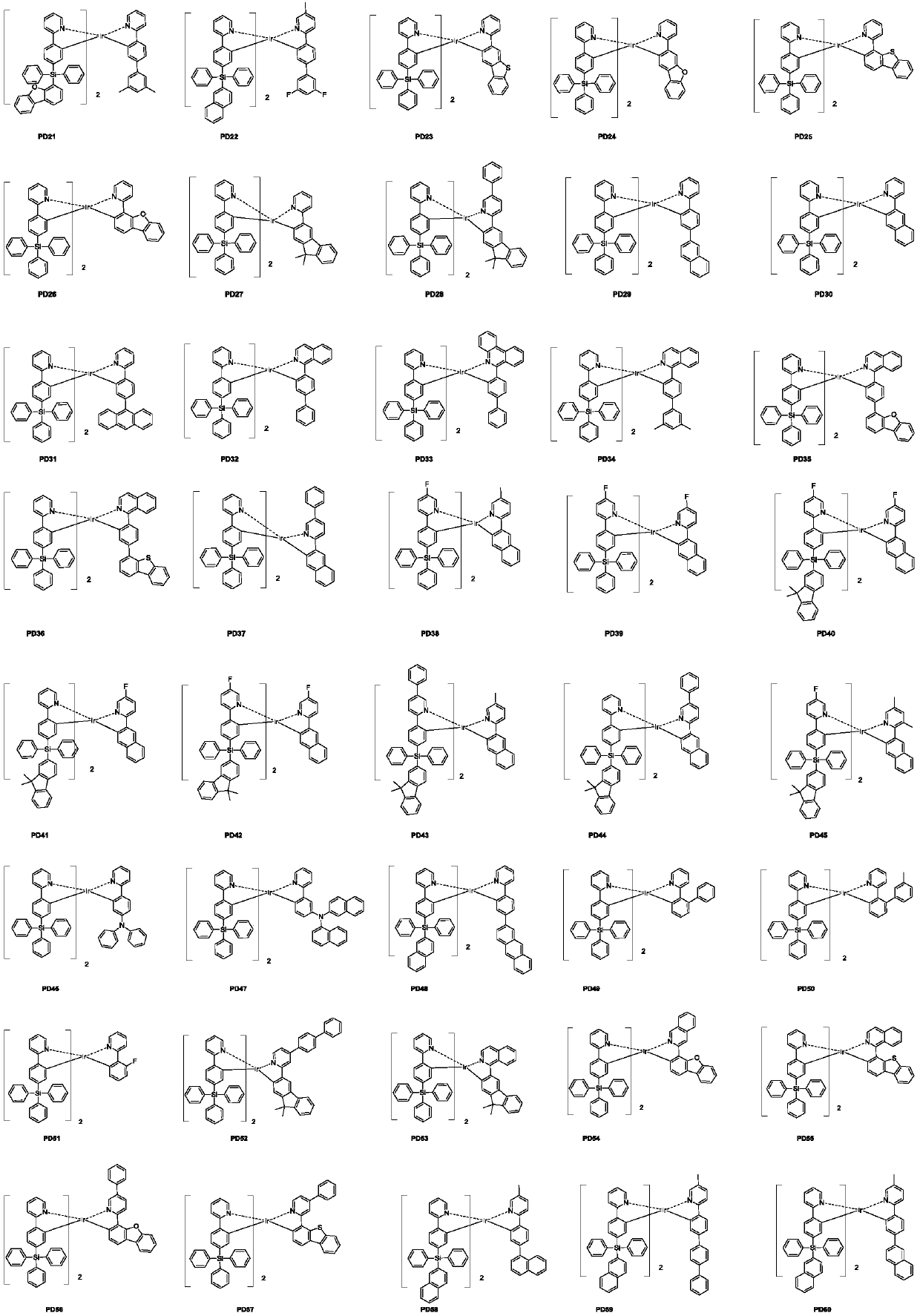

[0068] Example 2: Compound PD25

[0069]

[0070] Intermediate 25-8 was synthesized according to the method of Example 1.

[0071] Add 12.87g (10.0mmol) of intermediate 25-8 into a three-necked flask, then add 150mL of absolute ethanol and 5.22g (20.0mmol) of intermediate 25-6, and stir the reaction at 90°C for 24 hours, and a large amount of solids precipitate out. TLC monitoring showed that the basic reaction of raw materials was completed. After suction filtration, the target product was obtained, rinsed with about 50 mL of petroleum ether, and dried to obtain 9.2 g of the product, with a yield of 72%, and the measured HPLC was 99%. MW: 1277.52.

Embodiment 3

[0072] Example 3: Compound PD34

[0073]

[0074] Add 12.87g (10.0mmol) of intermediate 34-8 into a three-necked flask, then add 150mL of absolute ethanol and 6.18g (20mmol) of intermediate 34-6, and stir the reaction at 90°C for 24 hours, and a large amount of solids precipitate out.

[0075] TLC monitoring showed that the basic reaction of raw materials was completed. After suction filtration, the target product was obtained, rinsed with about 50 mL of petroleum ether, and dried to obtain 10.34 g of product PD34, with a yield of 78%, and a HPLC value of 99%. MW: 1325.41.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com