Method for detecting heterocyclic amines in grease

A technology for heterocyclic amines and oils, applied in the detection field of heterocyclic amines, can solve the problems of carcinogenicity, mutagenicity, pollution, etc., and achieve the effect of short time consumption and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

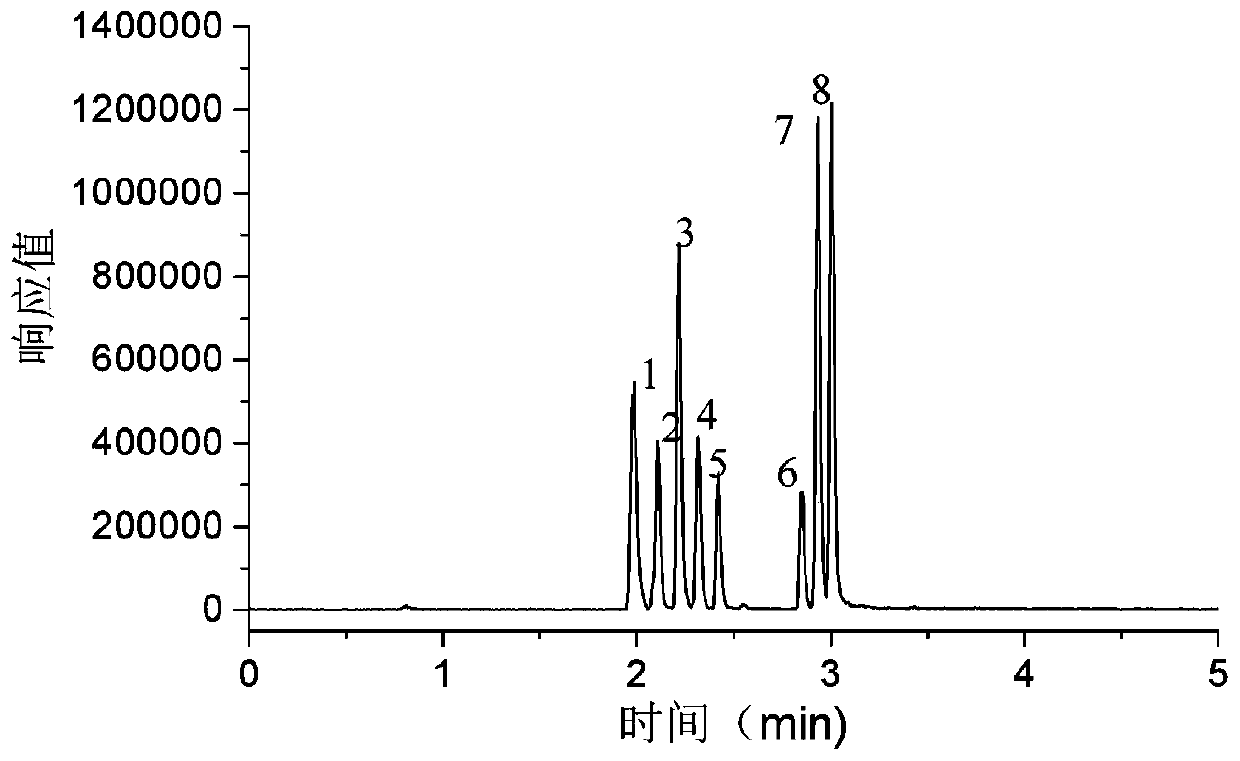

[0081] After placing 2 g of soybean oil in a polypropylene centrifuge tube, add 40 μL of internal standard working solution (4,7,8-TriMeIQx solution, concentration: 1.0 μg / mL) and 10 mL of 1% ammonia acetonitrile solution in sequence, vortex for 5 min, and sonicate for 10 min , centrifuge at a speed of 3500r / min for 5min to obtain the first supernatant and residue;

[0082] The residue was repeatedly extracted once according to the above steps to obtain a second supernatant;

[0083] After mixing the first supernatant and the second supernatant, add 10 mL of saturated n-hexane solution of acetonitrile for degreasing to obtain a degreased extract solution (10 mL);

[0084] The extraction solution after the degreasing is loaded (sample loading speed is 1mL / min) in advance with 3mL methanol, the PCX solid-phase extraction column activated by 3mL ultrapure water, then with 3mL0.1mol / L hydrochloric acid and 3mL methanol Rinse the small column, drain it after rinsing, and elute wit...

Embodiment 2

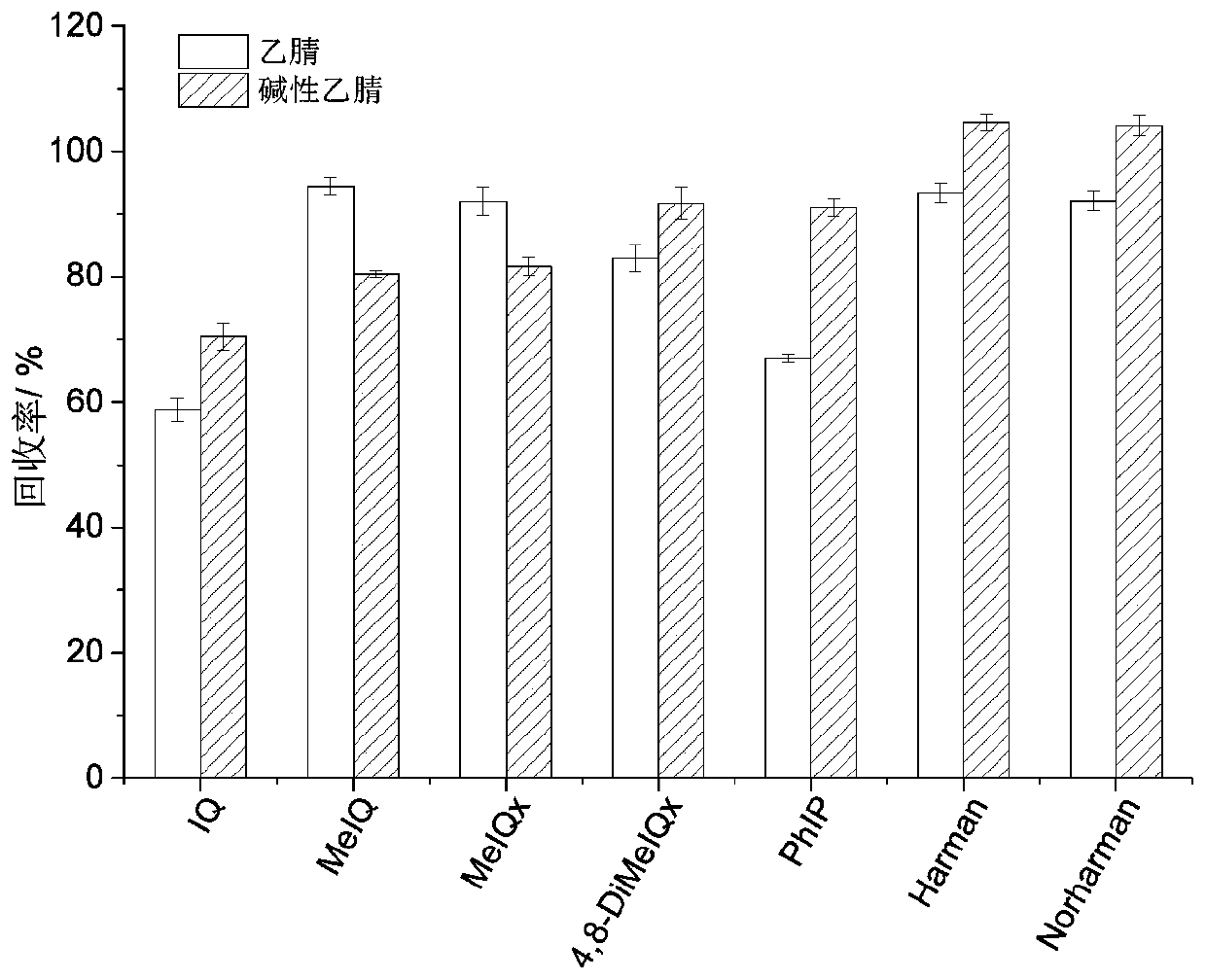

[0096] After placing 2 g of soybean oil in a polypropylene centrifuge tube, add 40 μL of internal standard working solution (4,7,8-TriMeIQx solution, concentration: 1.0 μg / mL) and 10 mL of acetonitrile solution in sequence, vortex for 5 min, sonicate for 10 min, 3500r Centrifuge 5min under the rotating speed of / min, obtain the first supernatant and residue;

[0097] The residue was repeatedly extracted once according to the above steps to obtain a second supernatant;

[0098] After mixing the first supernatant and the second supernatant, add 10 mL of saturated n-hexane solution of acetonitrile for degreasing to obtain a degreased extract solution (10 mL);

[0099]The extraction solution after the degreasing is loaded (sample loading speed is 1mL / min) in advance with 3mL methanol, the PCX solid-phase extraction column activated by 3mL ultrapure water, then with 3mL0.1mol / L hydrochloric acid and 3mL methanol Rinse the small column, drain it after rinsing, and elute with 3mL me...

Embodiment 3

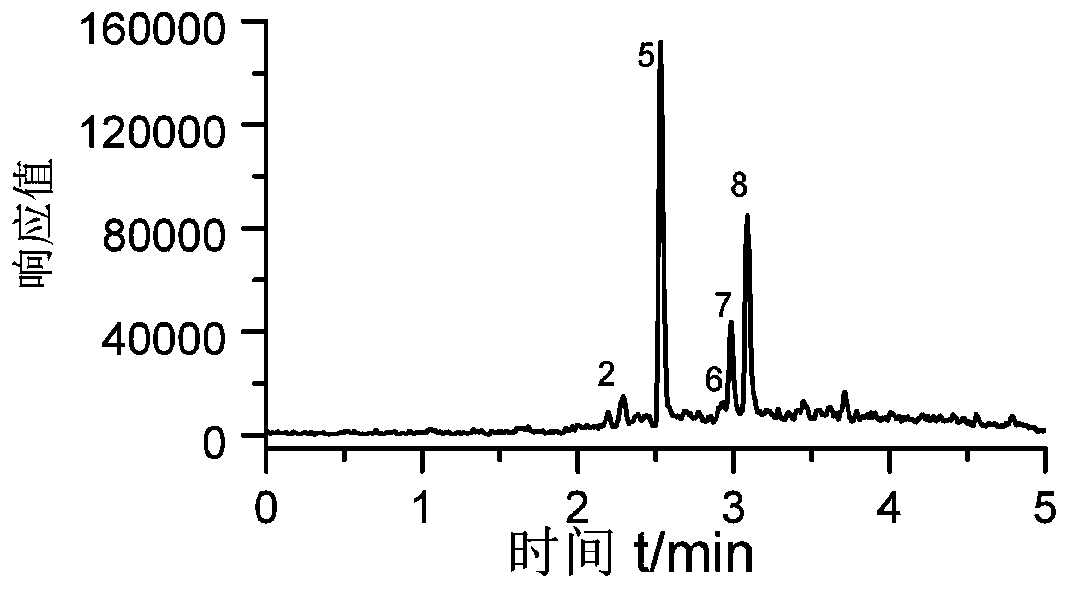

[0110] After placing 1 g of sesame oil in a polypropylene centrifuge tube, add 80 μL of internal standard working solution (4,7,8-TriMeIQx solution, the concentration is 500 ng / mL) and 10 mL of 1% ammonia acetonitrile solution in sequence, vortex for 5 min, sonicate for 10 min, 3500r Centrifuge 5min under the rotating speed of / min, obtain the first supernatant and residue;

[0111] The residue was repeatedly extracted once according to the above steps to obtain a second supernatant;

[0112] After mixing the first supernatant and the second supernatant, add 10 mL of saturated n-hexane solution of acetonitrile for degreasing to obtain a degreased extract solution (10 mL);

[0113] The extraction solution after the degreasing is loaded (sample loading speed is 1mL / min) in advance with 3mL methanol, the PCX solid-phase extraction column activated by 3mL ultrapure water, then with 3mL0.1mol / L hydrochloric acid and 3mL methanol Rinse the small column, drain it after rinsing, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com