A kind of high-strength alkali-free liquid quick-setting agent, preparation method and application thereof

An accelerator and high-strength technology, applied in the field of building materials, can solve the problems of high dosage, narrow cement adaptability, and high cost, and achieve the effects of low dosage, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

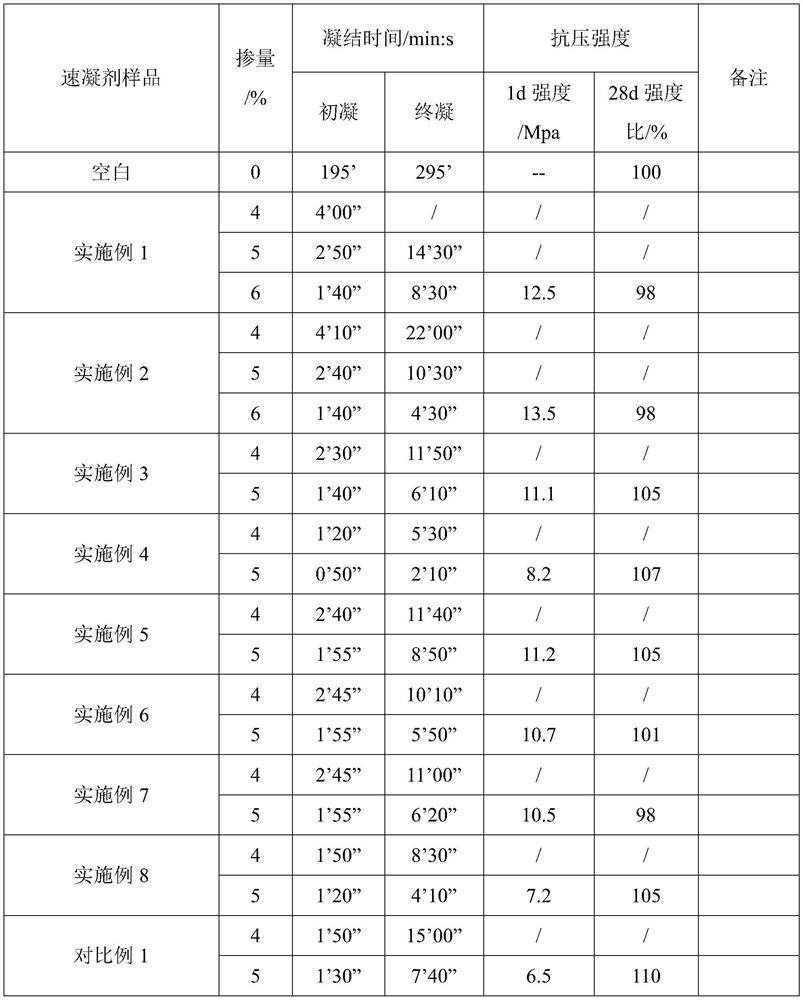

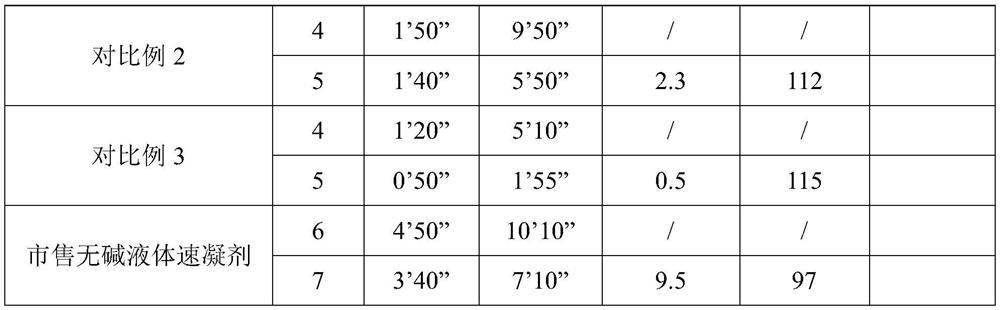

Examples

Embodiment 1

[0044] A high-strength alkali-free liquid quick-setting agent, comprising the following components, calculated in parts by weight:

[0045] Aluminum sulfate 37 parts; aluminum hydroxide 3.5 parts; hydrofluoric acid 7 parts; magnesium sulfate 8 parts; magnesium oxide 2.4 parts; tween-20 0.8 parts; precipitated hydrated magnesium silicate 0.7 parts; water 38 parts.

[0046] Preparation method of high-strength alkali-free liquid quick-setting agent

[0047] S1 Preparation of Fluoroaluminum Complex Solution

[0048] Weigh the following materials in proportion, first add water, precipitated hydrated magnesium silicate, fluorosilicate and aluminum hydroxide, after pre-dispersing for 0.5h, continue to slowly add hydrofluoric acid solution, the reaction temperature is 90-95°C, and wait for the reaction to complete Finally, the mixed solution is obtained, and the mixed solution is kept insulated at a temperature of 85 to 90° C. until the free hydrofluoric acid in the excess mixed soluti...

Embodiment 2

[0052] A high-strength alkali-free liquid quick-setting agent, comprising the following components, calculated in parts by weight:

[0053] 37 parts of aluminum sulfate; 3.5 parts of aluminum hydroxide; 7 parts of hydrofluoric acid; 8 parts of magnesium sulfate; 2.4 parts of magnesium oxide; 0.8 parts of fluorosilicate; 0.8 parts of tween-20; share.

[0054] Preparation method of high-strength alkali-free liquid quick-setting agent

[0055] S1 Preparation of Fluoroaluminum Complex Solution

[0056] Weigh the following materials in proportion, first add water, precipitated hydrated magnesium silicate, fluorosilicate and aluminum hydroxide, after pre-dispersing for 0.5h, continue to slowly add hydrofluoric acid solution, the reaction temperature is 90-95°C, and wait for the reaction to complete Finally, the mixed solution is obtained, and the mixed solution is kept insulated at a temperature of 85 to 90° C. until the free hydrofluoric acid in the excess mixed solution is fract...

Embodiment 3

[0060] A high-strength alkali-free liquid quick-setting agent, comprising the following components, calculated in parts by weight:

[0061] 37 parts of aluminum sulfate; 7 parts of aluminum hydroxide; 16 parts of hydrofluoric acid; 8 parts of magnesium sulfate; 2.4 parts of magnesium oxide; 1.2 parts of fluorosilicate; 0.8 parts of tween-20; share.

[0062] Preparation method of high-strength alkali-free liquid quick-setting agent

[0063] S1 Preparation of Fluoroaluminum Complex Solution

[0064] Weigh the following materials in proportion, first add water, precipitated hydrated magnesium silicate, fluorosilicate and aluminum hydroxide, after pre-dispersing for 0.5h, continue to slowly add hydrofluoric acid solution, the reaction temperature is 90-95°C, and wait for the reaction to complete Finally, the mixed solution is obtained, and the mixed solution is kept insulated at a temperature of 85 to 90° C. until the free hydrofluoric acid in the excess mixed solution is fracti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com