Slow-drying type batch-scraping sand wall paint and preparation method thereof

A dry-type, sand-scraping technology, used in biocide-containing paints, coatings, antifouling/underwater coatings, etc., which can solve problems such as short construction opening time, fast drying of sand wall paint, and poor leveling of sand wall paint. , to achieve the effect of extending the construction opening time, the construction opening time is long, and the surface drying time is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

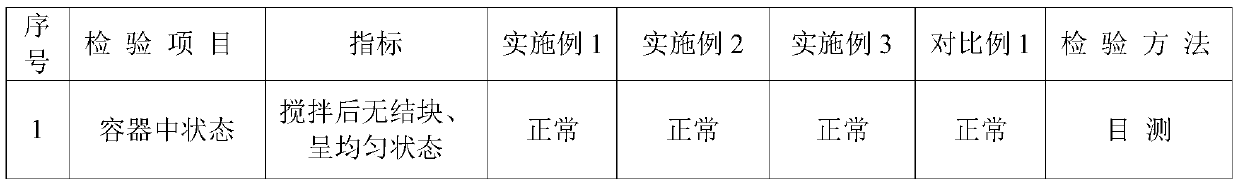

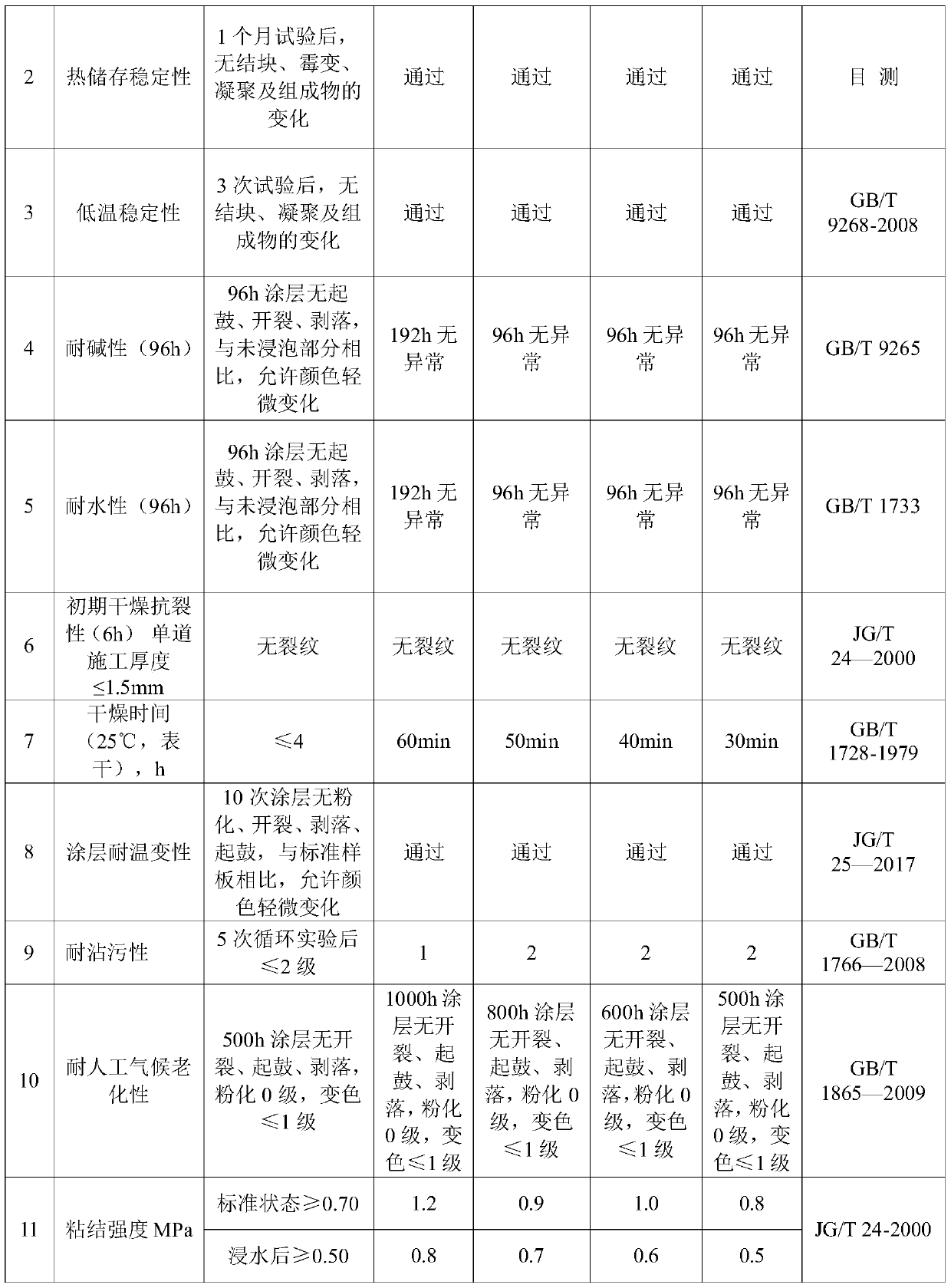

Embodiment 1

[0040] The slow-drying batch sand-scraping wall paint described in this example has a formula calculated by mass percentage and consists of the following components: deionized water 22wt%, preservative (MERGAL K9N) 0.3wt%, hydroxyethyl cellulose (QP 100MH ) 0.2wt%, pH adjuster (AMP-95) 0.2wt%, thermosetting super absorbent resin 5wt%, wetting agent (TRITON CF-10) 0.3wt%, propylene glycol 1.5wt%, slow-drying film-forming aid (OE -300) 1.2wt%, wood fiber (JRS-FD40) 0.2wt%, titanium dioxide (R-996) 0.5wt%, diatomaceous earth (CD05) 1.5wt%, styrene acrylic emulsion (DC420V) 15wt%, slow water Dry agent (M-30) 0.8wt%, defoamer (SN1360) 1.2wt%, water absorbing stone powder (80 mesh) 50wt%, polyurethane thickening and leveling agent (RM-2020) 0.1wt%.

[0041] In this embodiment, the components are prepared according to the following steps:

[0042] (1) In the reaction kettle, add deionized water according to the formula amount, place it under the high-speed disperser, start the high-speed...

Embodiment 2

[0047] The slow-drying batch sand-scraping wall paint described in this example has a formula calculated by mass percentage and consists of the following components: deionized water 23.5wt%, preservative (MERGAL K9N) 0.2wt%, hydroxyethyl cellulose (QP 100MH) 0.2wt%, pH adjuster (AMP-95) 0.2wt%, thermosetting super absorbent resin 3wt%, wetting agent (TRITON CF-10) 0.2wt%, propylene glycol 1.1wt%, slow-drying film forming aid ( OE-300) 1.2wt%, wood fiber (JRS-FD40) 0.1wt%, titanium dioxide (R-996) 0.5wt%, diatomaceous earth (CD05) 1wt%, styrene acrylic emulsion (DC420V) 12wt%, slow water Dry agent (M-30) 0.6wt%, defoamer (SN1360) 1.1wt%, water absorbing stone powder (80 mesh) 55wt%, polyurethane thickening and leveling agent (RM-2020) 0.1wt%.

[0048] In this embodiment, the components are prepared according to the following steps:

[0049] (1) In the reaction kettle, add deionized water according to the formula amount, place it under the high-speed disperser, start the high-speed ...

Embodiment 3

[0054] The slow-drying batch sand-scraping wall paint described in this example has a formula calculated by mass percentage and consists of the following components: deionized water 27wt%, preservative (MERGAL K9N) 0.2wt%, hydroxyethyl cellulose (QP 100MH ) 0.3wt%, pH adjuster (AMP-95) 0.1wt%, thermosetting super absorbent resin 2wt%, wetting agent (TRITON CF-10) 0.2wt%, propylene glycol 1wt%, slow-drying film forming aid (OE- 300) 1wt%, wood fiber (JRS-FD40) 0.2wt%, titanium dioxide (R-996) 0.3wt%, diatomaceous earth (CD05) 0.6wt%, styrene-acrylic emulsion (DC420V) 10wt%, water-based slow-drying agent (M-30) 0.8wt%, defoamer (SN1360) 1.0wt%, water absorbing stone powder (80 mesh) 55wt%, polyurethane thickening and leveling agent (RM-2020) 0.3wt%.

[0055] In this embodiment, the components are prepared according to the following steps:

[0056] (1) In the reaction kettle, add deionized water according to the formula amount, place it under the high-speed disperser, start the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com