Catalytic cracking raw material pretreatment method and light oil production method and system

A catalytic cracking raw material and catalytic cracking technology, applied in catalytic cracking, hydrocarbon oil treatment, cracking and other directions, can solve the problems of large modification of the original device, insufficient reaction depth, high olefin content, low maintenance cost, reduced coking performance, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

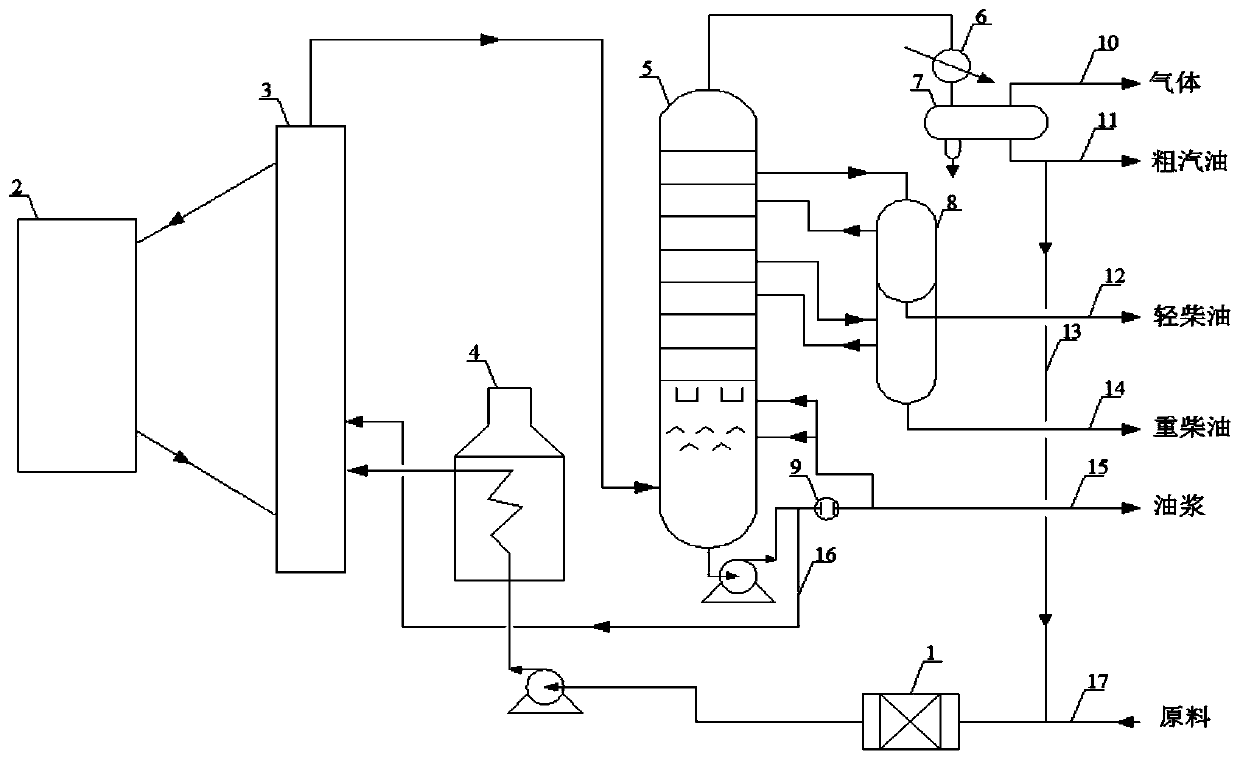

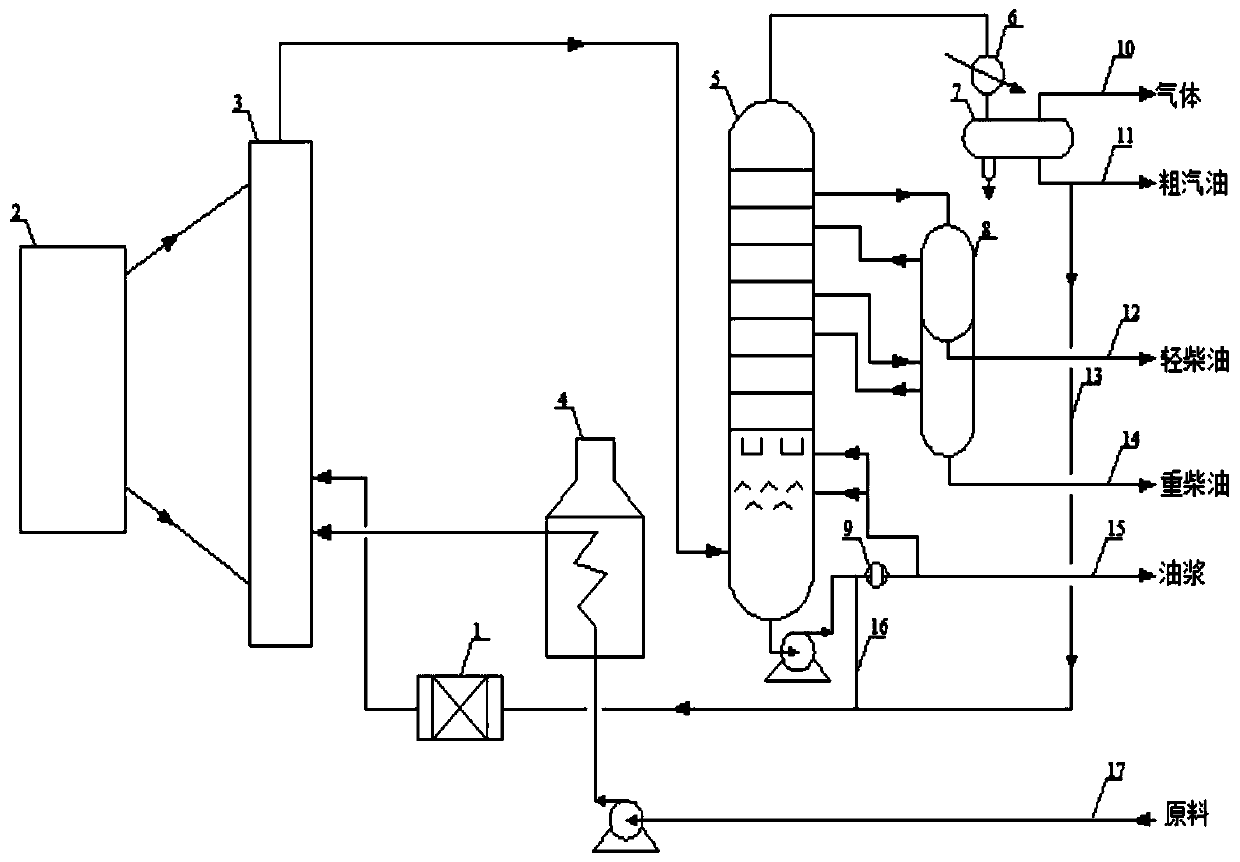

Method used

Image

Examples

Embodiment 1

[0065] This embodiment provides a light oil production method. details as follows:

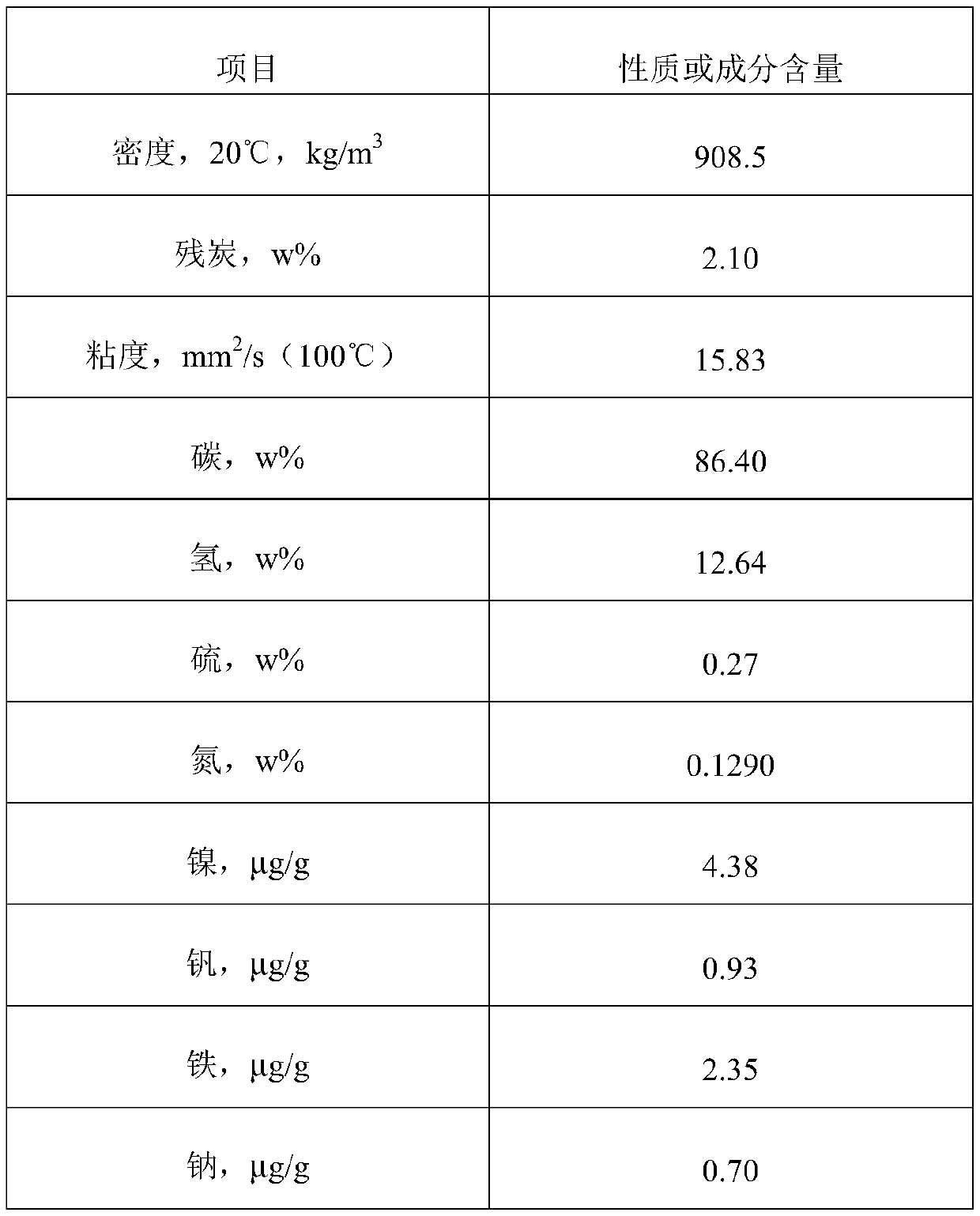

[0066] The raw material for catalytic cracking is mixed wax oil blended with normal oil pressure residue. Its main properties and components are shown in Table 1. The catalyst is CC-20D catalytic cracking industrial equilibrium catalyst in SRY molecular sieve, with a microreactivity of 65.

[0067] The catalytic cracking raw material is subjected to cavitation pretreatment, the cavitation pretreatment device is a Venturi tube cavitation device, and the cavitation pretreatment reaction condition is: reaction pressure 4Mpa.

[0068] The operation mode in the catalytic cracking reaction process is single-pass cracking, and the reaction conditions are: the reactor outlet temperature is 490°C, the regenerator temperature is 685°C, the feedstock preheating temperature is 234°C, the reaction pressure is 0.131Mpa, the solvent-to-oil ratio is 5.9, and the reaction time is 2.85s.

[0069] Table 1 Prope...

Embodiment 2-10

[0073] The operating conditions of the catalytic cracking reaction process of Examples 2-10 are the same as those of Example 1, except that the operating conditions of cavitation pretreatment are different.

Embodiment 2

[0074] Example 2 The cavitation pretreatment reaction conditions are: the reaction pressure is normal pressure 6Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com