A compound cleaning agent for live insulating equipment

A hydrocarbon cleaning agent and equipment technology, applied in the field of cleaning agents, can solve the problems of unsuitable cleaning of charged equipment, low aniline point of hydrocarbon cleaning agents, and reduced drying speed of workpieces, etc., to achieve good antistatic ability and good emulsification penetration Ability and small residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

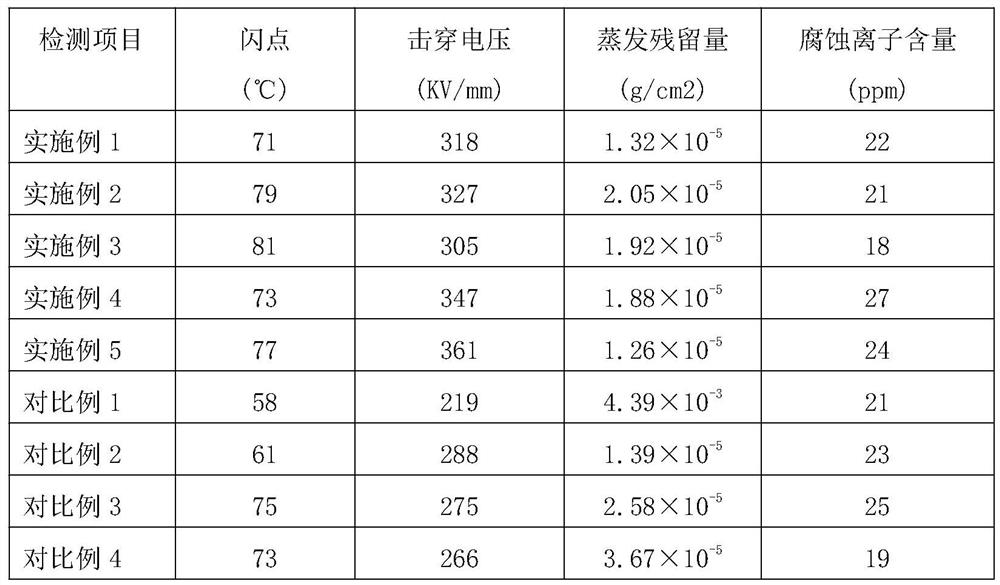

Examples

Embodiment 1

[0015] Put 64 parts of C9-C12 normal paraffin and isoparaffin solvent into the reaction kettle, stir and mix to form alkane hydrocarbon solvent, add 16 parts of hexabromocyclohexane into the hydrocarbon solvent, stir and mix well, Form a hydrocarbon cleaning agent; mix 11.5 parts of 1-ethyl-2,3-dimethylpentadecylbenzenesulfonic acid imidazolium salt and 3.5 parts of fatty alcohol polyoxyethylene ether at room temperature, ultrasonically disperse for 2 hours, and stir Add it to the hydrocarbon cleaning agent in the state, then add 5 parts of the stabilizer, stir and mix well to get the composite hydrocarbon cleaning agent.

Embodiment 2

[0017] Put 72 parts of C9-C12 normal paraffin and isoparaffin solvent into the reaction kettle, stir and mix to form alkane hydrocarbon solvent, add 18 parts of tetrabromocyclooctane into the hydrocarbon solvent, stir and mix, Form a hydrocarbon cleaning agent; mix 6.2 parts of 1-ethyl-2,3-dimethylpentadecylbenzenesulfonic acid imidazolium salt and 1.8 parts of fatty alcohol polyoxyethylene ether at room temperature, ultrasonically disperse for 2 hours, and stir Add it to the hydrocarbon cleaning agent in the state, then add 2 parts of the stabilizer, stir and mix well to get the composite hydrocarbon cleaning agent.

Embodiment 3

[0019] Put 72 parts of C9-C12 normal paraffin and isoparaffin solvent into the reaction kettle, stir and mix to form alkane hydrocarbon solvent, add 9 parts of hexabromocyclohexane and 9 parts of tetrabromocyclooctane to the carbon In a hydrogen solvent, stir and mix to form a hydrocarbon cleaning agent; at room temperature, mix 6.2 parts of 1-ethyl-2,3-dimethylpentadecylbenzenesulfonic acid imidazolium salt and 1.8 parts of fatty alcohol polyoxyethylene ether Mix, ultrasonically disperse for 2 hours, add to the hydrocarbon cleaning agent under stirring, then add 2 parts of stabilizer, stir and mix well, and obtain the composite hydrocarbon cleaning agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com