Iodometry-based method for measuring concentration of peroxide in peroxo-monosulfate, peroxo-disulfate and hydrogen peroxide mixed solution

A technology of peroxodisulfate and hydrogen peroxide, which is applied in the direction of chemical analysis by titration, and can solve the problems of inability to measure the respective concentrations of the three oxidants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

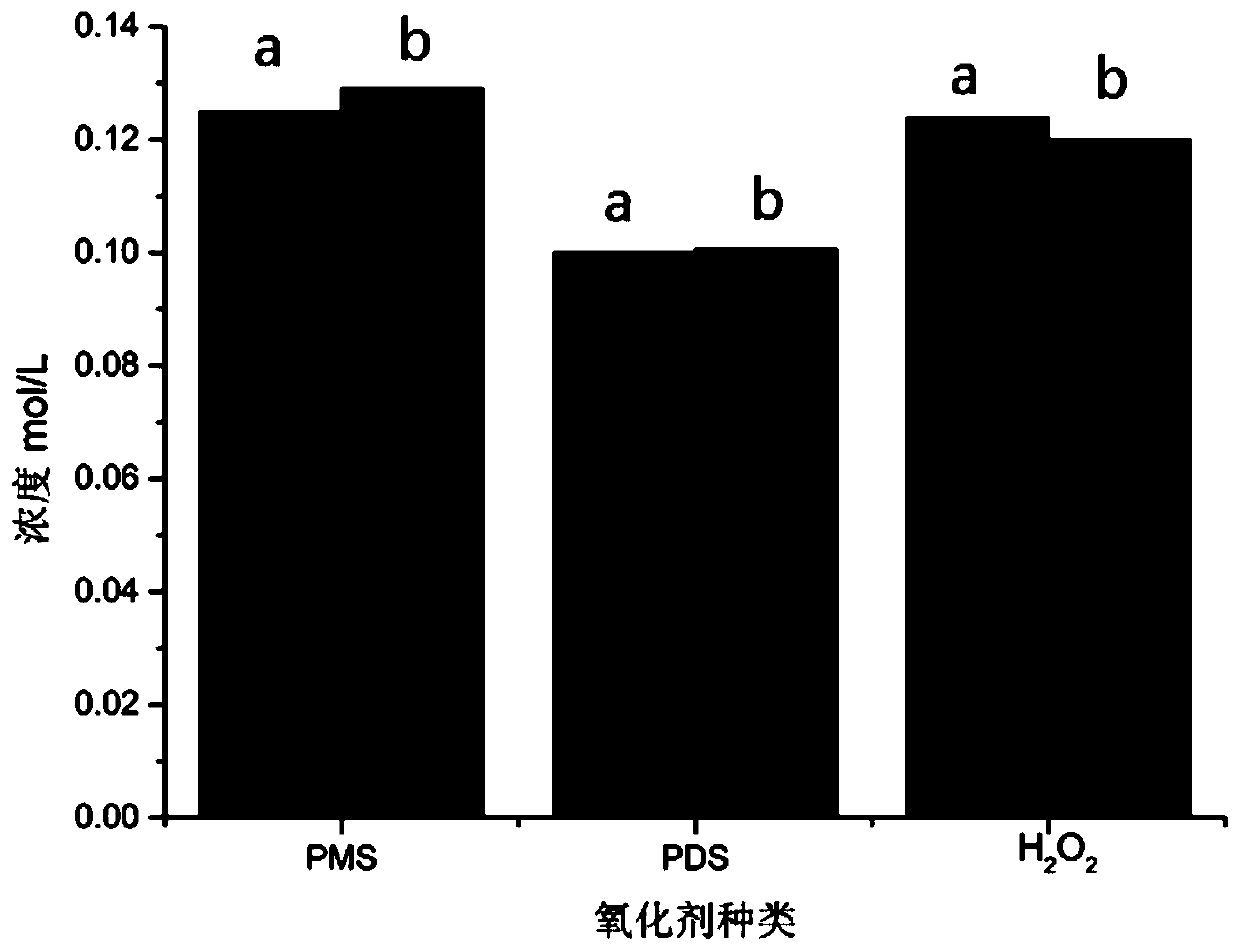

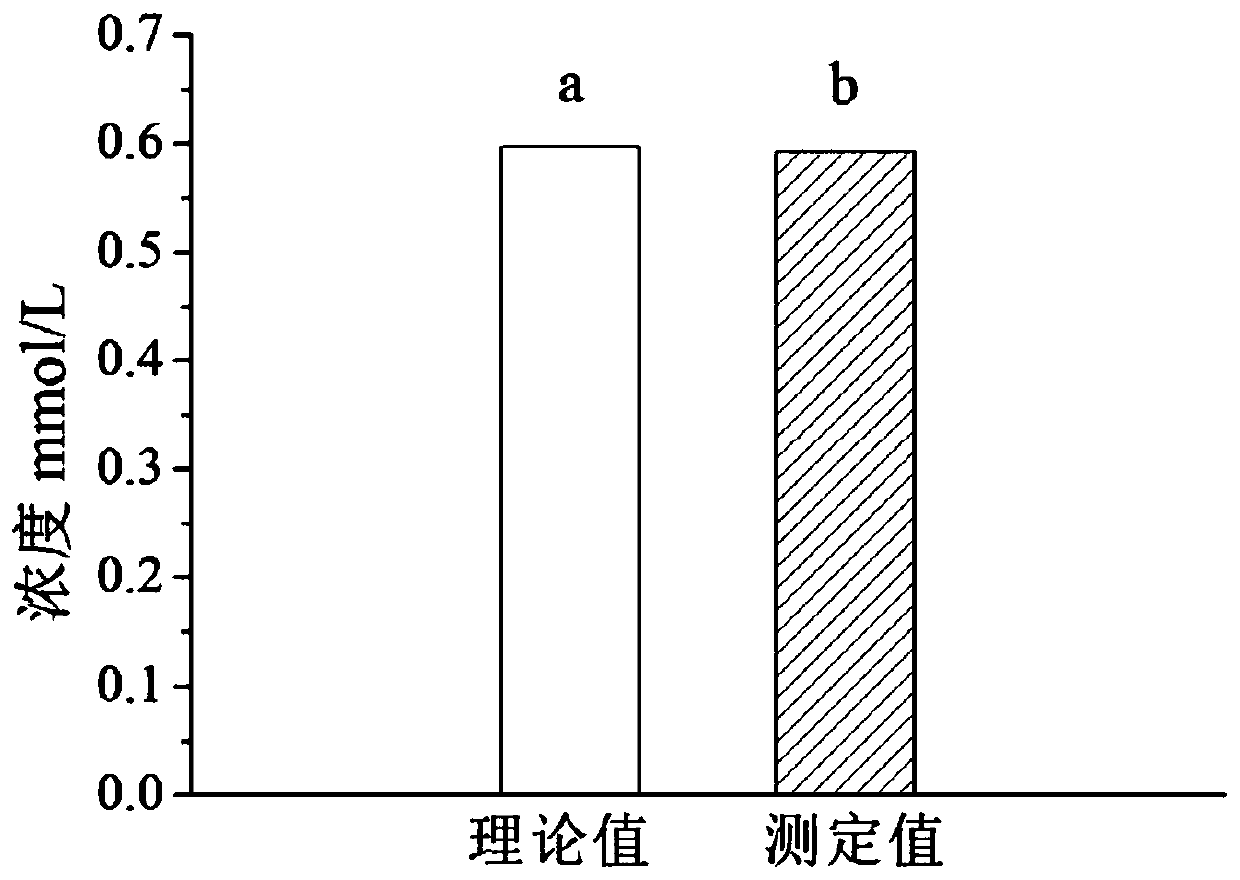

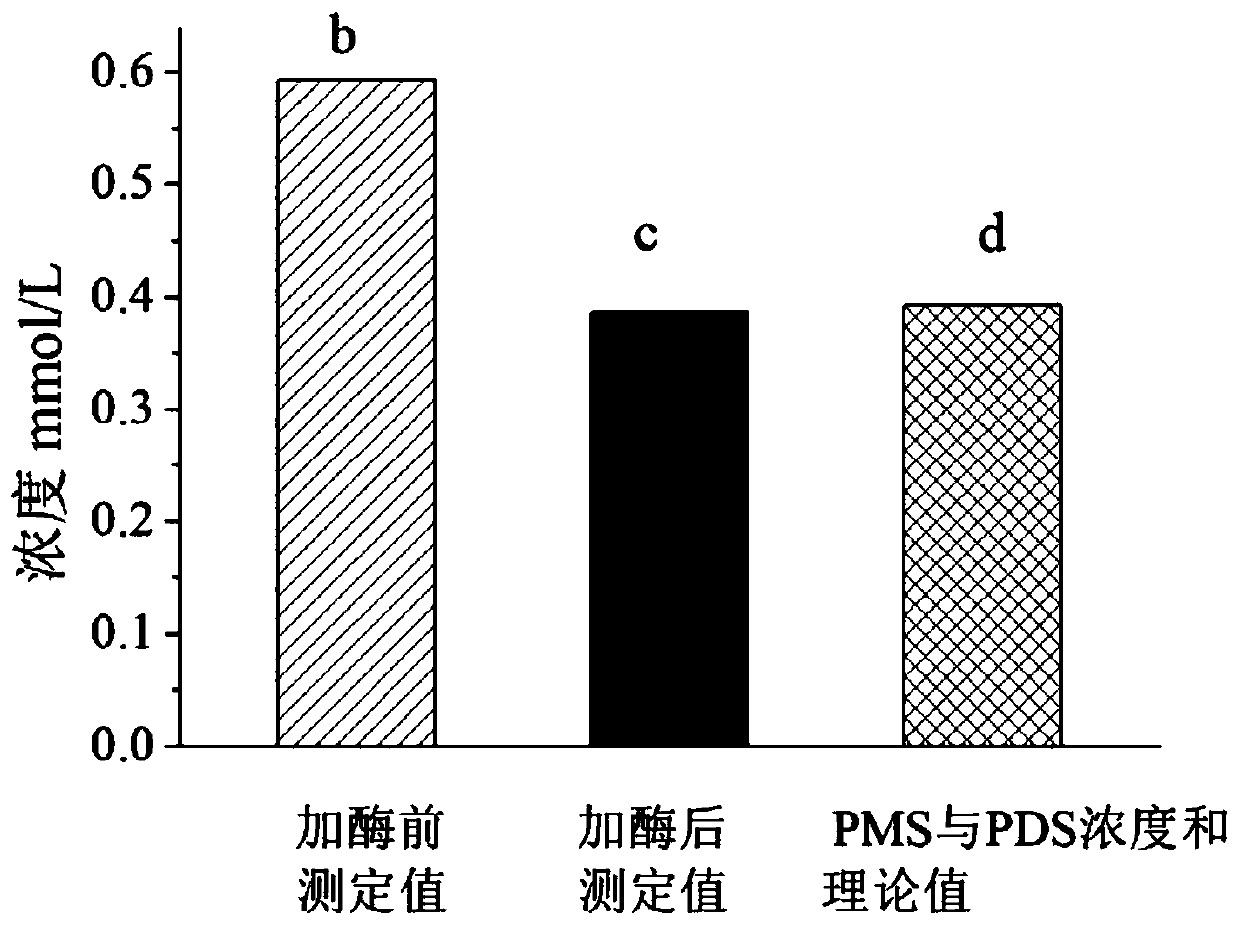

[0016] The specific embodiment one: the present embodiment measures the method for each peroxide concentration in peroxomonosulfate, peroxodisulfate and hydrogen peroxide mixed solution based on iodometric method, according to the following steps:

[0017] 1. Take x mL of the solution to be tested, add sodium bicarbonate and potassium iodide, shake well, let it stand for 15-20min, add glacial acetic acid, shake well, and use a concentration of c 0 Titration of mol / L sodium thiosulfate solution, using starch as indicator, after titrating the solution to colorless, record the amount of sodium thiosulfate h 1 mL;

[0018] 2. Take another x mL of the solution to be tested, add sodium monohydrogen phosphate-sodium dihydrogen phosphate buffer solution, catalase solution, shake well, let it stand for 5-10min, add sodium bicarbonate and potassium iodide, shake well, let stand After 15-20min, add glacial acetic acid with a concentration of c 0 Titration of mol / L sodium thiosulfate...

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the concentration of potassium iodide in the test solution in step 1 and step 2 is ≥1.81mol / L, and the concentration of sodium bicarbonate is 0.79mmol / L. Others are the same as the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the volume ratio of glacial acetic acid and the liquid to be tested is 3.3:(100-101) in step 1 and step 2. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com