Nano particle of core-shell structure with amorphous Fe coated with crystalline Fe3O4 and preparation method and application of nano particle

A nanoparticle, core-shell structure technology, applied in the field of magnetic nanomaterials, to achieve the effect of controllable shape, uniform particle size, and suppression of T2 effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) First measure 15 mL of octadecene in a three-necked flask, and add 0.3 mL of oleylamine;

[0037] (2) Then stir while heating, and discharge air into the three-necked bottle with nitrogen, raise the temperature to 185-190°C, and replace the nitrogen balloon for protection;

[0038] (3) Add 0.7 mL of iron source solution (i.e. iron pentacarbonyl) to it, and react for 28 minutes;

[0039] (4) Add 0.3mL oleic acid, react for 10min, continue to heat up to 260°C, crystallize for 40min, cool down, centrifuge, and the reaction ends to obtain crystalline Fe 3 o 4 Nanoparticles coated with amorphous Fe core-shell structure.

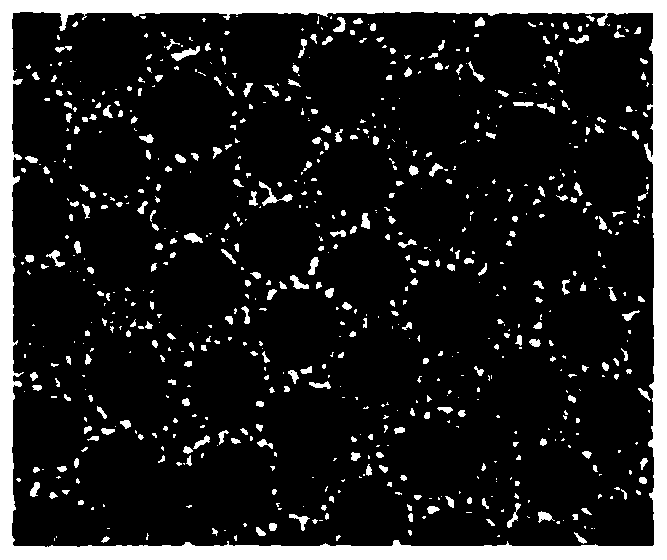

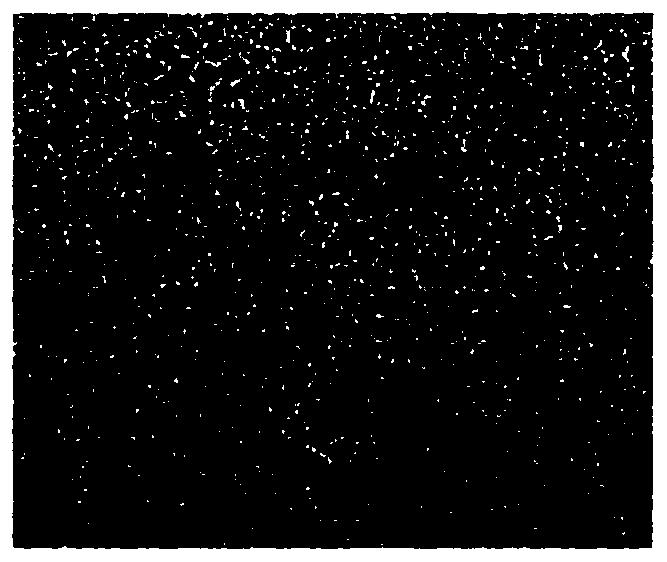

[0040] Such as Figure 1a As shown, the prepared 8nm Fe@Fe 3 o 4 The particle size of nanoparticles is ultra-small and uniform, with good dispersion and no agglomeration.

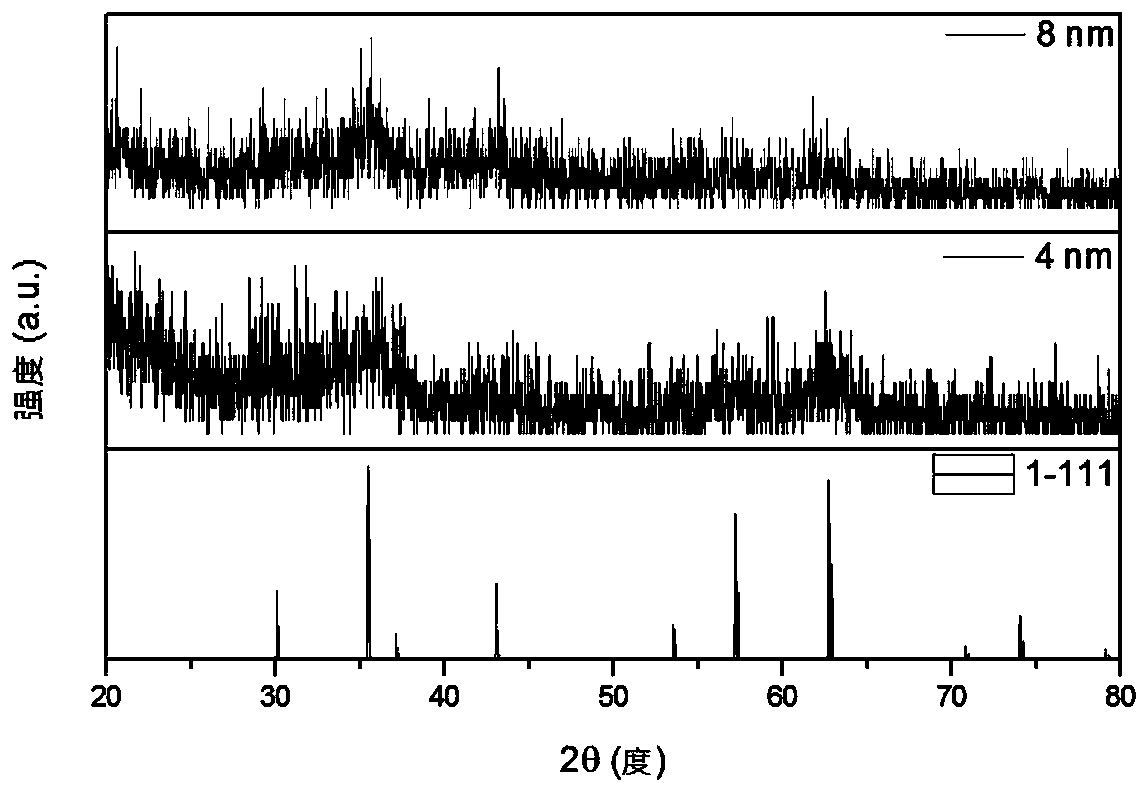

[0041] Such as figure 2 As shown, Fe 3 o 4 Correspondingly, there is no obvious Fe peak, indicating that the Fe core is amorphous, and the outermost Fe 3 o 4 The shell pre...

Embodiment 2

[0046] (1) First measure 15 mL of octadecene in a three-necked flask, and add 0.2 mL of oleylamine;

[0047] (2) Then stir while heating, and discharge air into the three-necked bottle with nitrogen, raise the temperature to 180-185°C, and replace the nitrogen balloon for protection;

[0048] (3) Add 0.7mL iron source solution (i.e. iron pentacarbonyl) to it, and react for 22min;

[0049] (4) Add 0.2mL oleic acid, react for 10min, continue to heat up to 260°C, crystallize for 40min, cool down, centrifuge, and the reaction is over to obtain crystalline Fe 3 o 4 Nanoparticles coated with amorphous Fe core-shell structure.

[0050] Such as Figure 1b As shown, the prepared 4nm Fe@Fe 3 o 4 The particle size of nanoparticles is ultra-small and uniform, with good dispersion and no agglomeration.

[0051] Such as figure 2 As shown, Fe 3 o 4 Correspondingly, there is no obvious Fe peak, indicating that the Fe core is amorphous, and the outermost Fe 3 o 4 The shell presents...

Embodiment 3

[0056] (1) First measure 20 mL of octadecene in a three-necked flask, and add 0.3 mL of oleylamine;

[0057] (2) Then stir while heating, and discharge air into the three-necked bottle with nitrogen, raise the temperature to 186-190°C, and replace the nitrogen balloon for protection;

[0058] (3) Add 0.7mL iron source solution (i.e. iron pentacarbonyl) to it, and react for 25min;

[0059] (4) Add 0.3mL oleic acid, react for 10min, cool down, centrifuge, the reaction is over, crystalline Fe 3 o 4 Nanoparticles coated with amorphous Fe core-shell structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com