Emetic device for emergency internal medicine

A technology for inducing vomiting and internal medicine, applied in the medical field, can solve the problems of patient injury, energy consumption, stimulation, etc., and achieve the effect of convenient disassembly and installation, convenient hand-held operation, and enhanced gag reflex.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

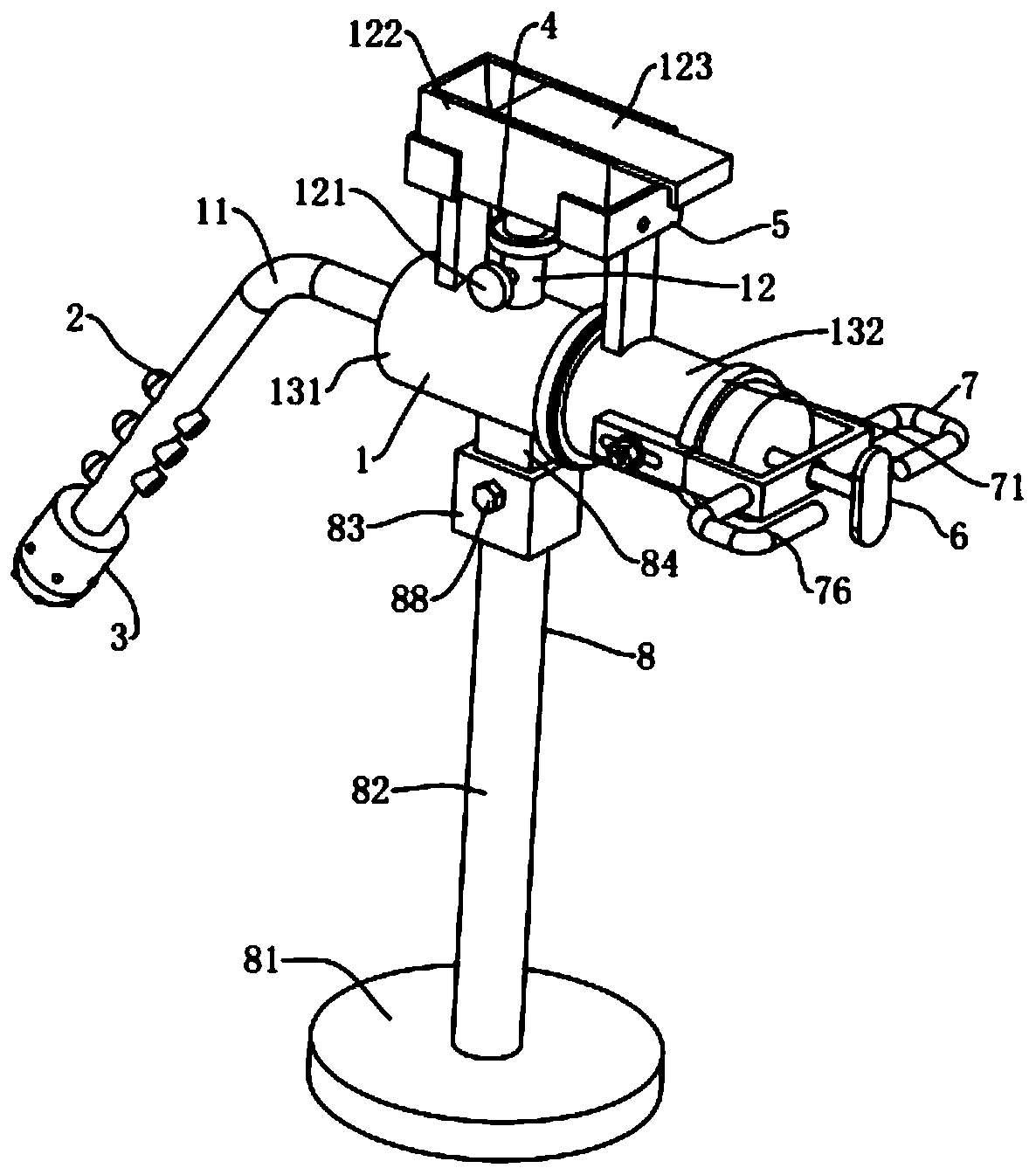

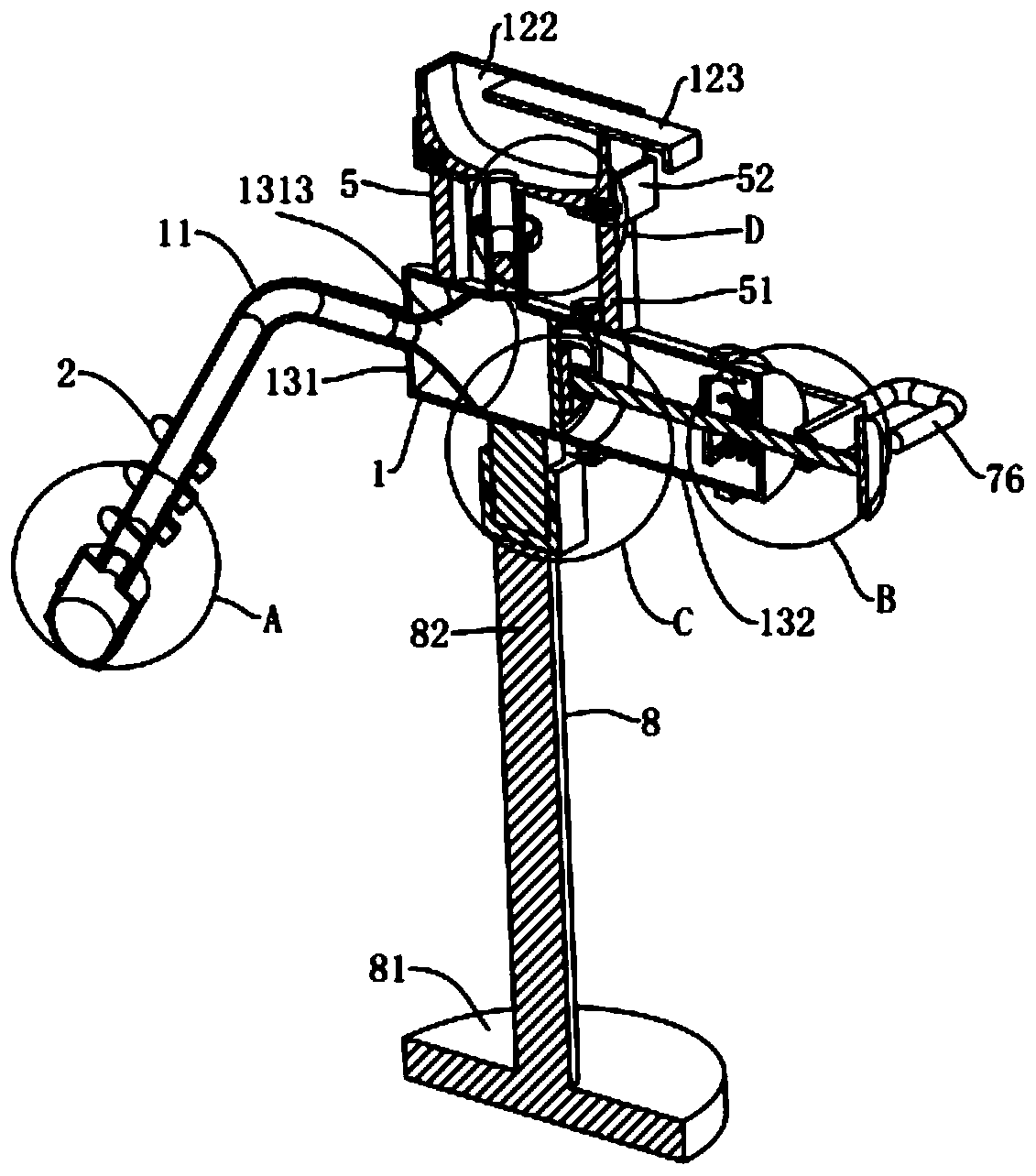

[0055] refer to figure 1 with figure 2 , an emetic device for emergency medicine, including a cartridge 1 for containing emetic drugs, wherein the device also includes the following parts:

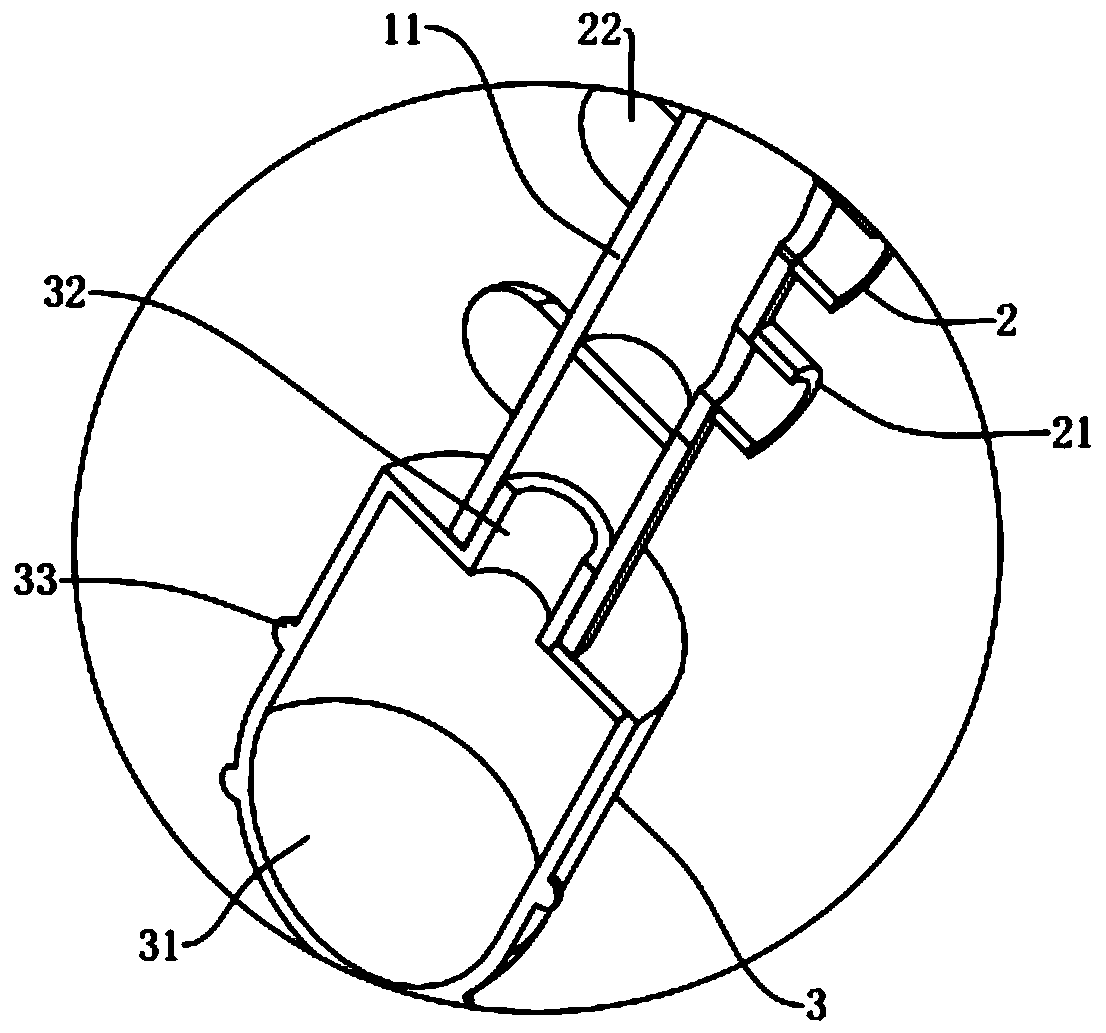

[0056] The insertion tube 11 connected to the end of the cartridge 1, wherein the insertion tube 11 is made of silicone material, and the insertion tube 11 is used to penetrate deep into the patient's oral cavity;

[0057] The reflex strengthening part 2 for intensifying the vomiting reflex provided on the insertion tube 11 uses the reflex strengthening part 2 to achieve the function of strengthening the vomiting reflex;

[0058] The tonsil stimulating part 3 connected to the end of the tube 11 away from the cartridge 1, wherein the tonsil stimulating part 3 is used to stimulate the patient's tonsils to induce vomiting reflex;

[0059] A drug injection tube 12 fixed on the drug cartridge 1, wherein the drug injection tube 12 communicates with the inside of the drug cartridge 1, and a va...

Embodiment 2

[0077] The difference from Example 1 is that the surface of the insertion tube 11 is also coated with a layer of anti-fouling coating. Since the insertion tube 11 needs to be inserted into the patient's oral cavity and directly to the patient's tonsil during the patient's treatment, Therefore, the protruding pipe 11 is easy to become dirty. In order to prevent the protruding part from becoming dirty and difficult to clean, a layer of antifouling coating is sprayed on the surface of the protruding part, wherein the antifouling coating is prepared by the following method:

[0078] Take the following raw materials for each component by weight: 150 parts of polytetrafluoroethylene, 120 parts of isopropylidene glycerol ethoxylated acrylate, 90 parts of polyvinyl chloride, 40 parts of methacrylic acid, fluorinated polyether silicone 40 parts of alkane, 20 parts of potassium oleate, 20 parts of triethanolamine oleate, 15 parts of copper tannate, 10 parts of hydroxyethylated fatty amin...

Embodiment 3

[0085] The difference from Example 2 lies in the preparation of the antifouling coating on the surface of the pipe 11, wherein the antifouling coating is prepared by the following method:

[0086] Take the following raw materials by weight for each component: 160 parts of polytetrafluoroethylene, 130 parts of isopropylidene glycerol ethoxylated acrylate, 100 parts of polyvinyl chloride, 43 parts of methacrylic acid, fluorinated polyether silicone 43 parts of alkane, 23 parts of potassium oleate, 23 parts of triethanolamine oleate, 16 parts of copper tannate, 10-15 parts of hydroxyethylated fatty amine, 10-15 parts of acrylic acid;

[0087] S1. Prepare anti-fouling coating pre-preparation solution; mix and stir polytetrafluoroethylene, isopropylidene glycerin ethoxylated acrylate, polyvinyl chloride, methacrylic acid and fluorinated polyether siloxane, and then add To the reactor and heated to 324 ° C, and then keep warm for 34 minutes;

[0088] S2. Preparation of antifouling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com