Double-beam laser welding optimization method

A technology of laser welding and optimization methods, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of ineffective guidance of welding process application, large adjustability of double-beam laser, and difficulty in grasping welding process. , to achieve the effect of improving welding quality and efficiency, good filling and balance, and uniform sample distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

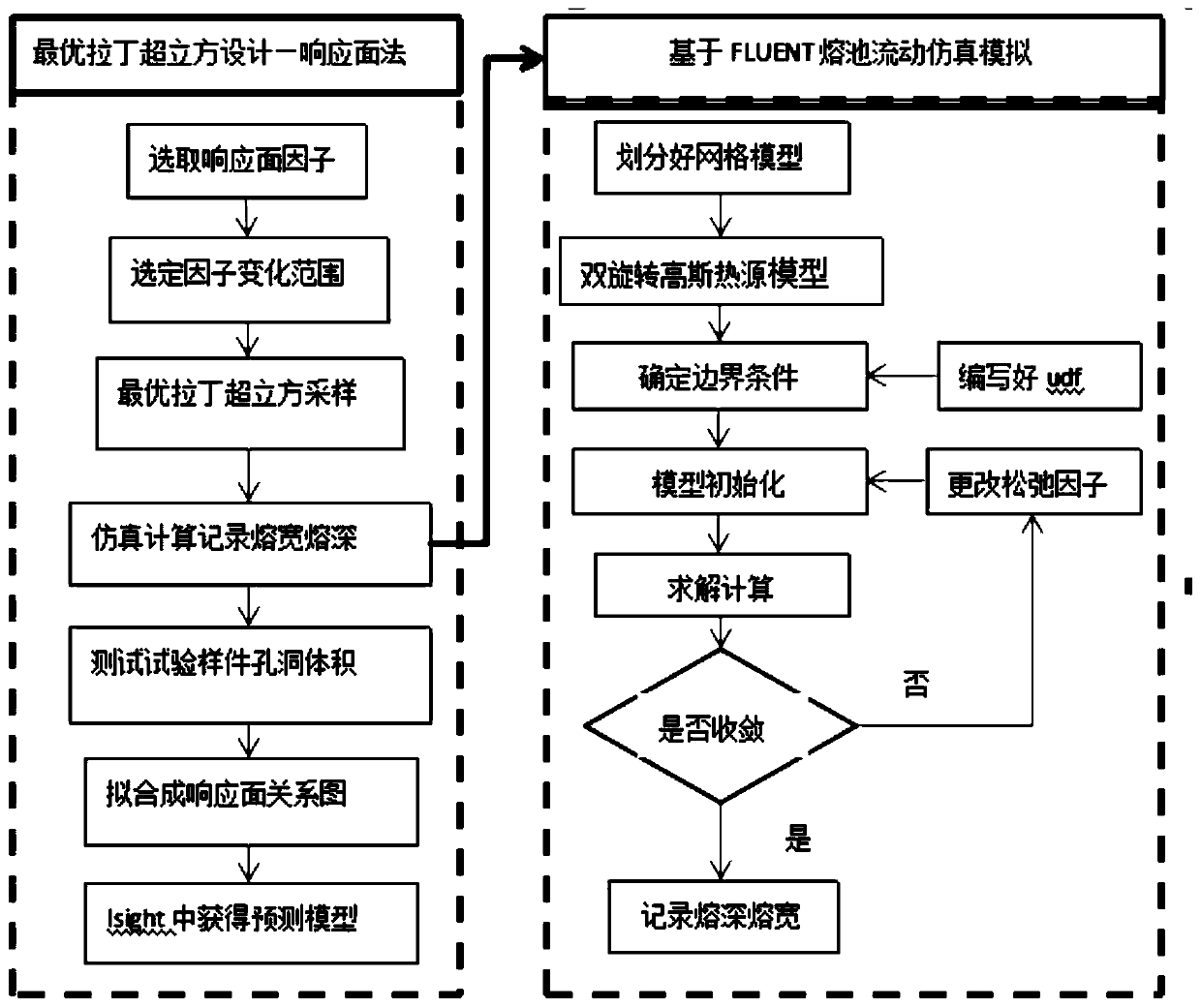

[0018] refer to Figure 1 to Figure 3 , a double-beam laser welding optimization method, comprising the following steps:

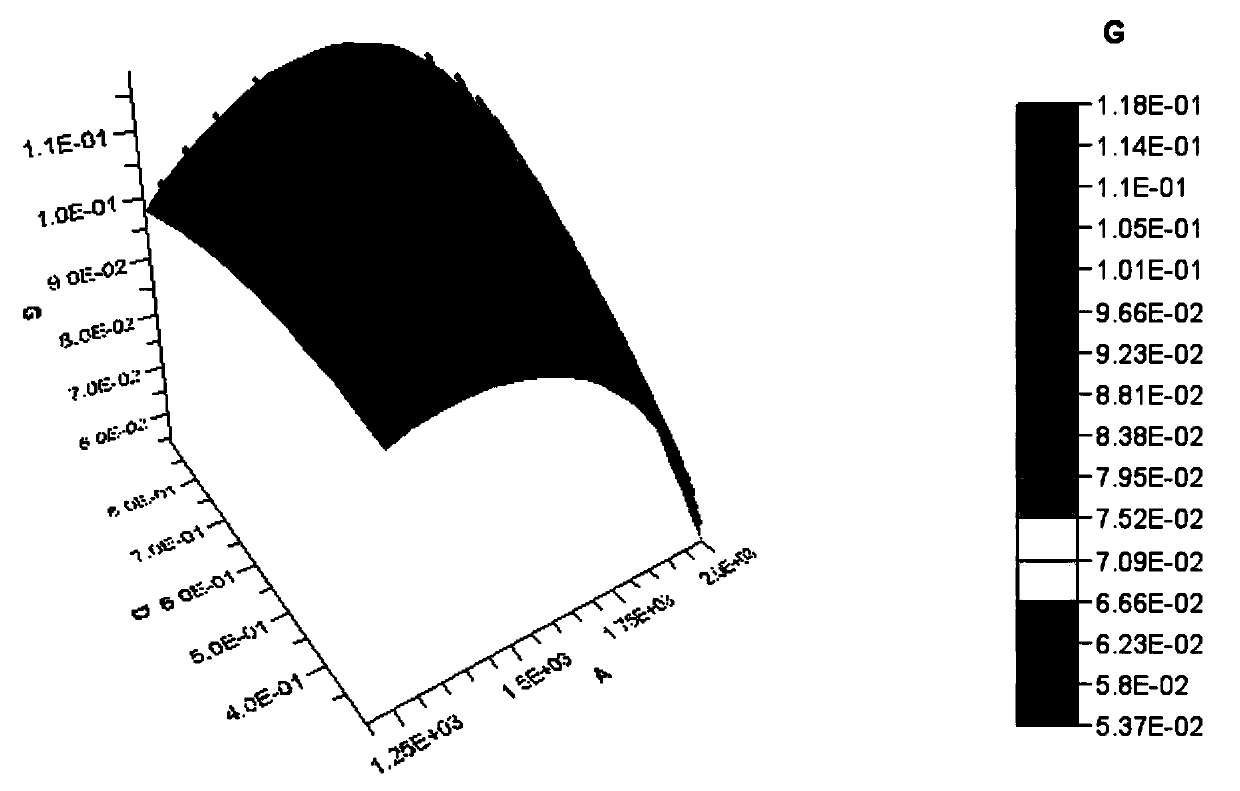

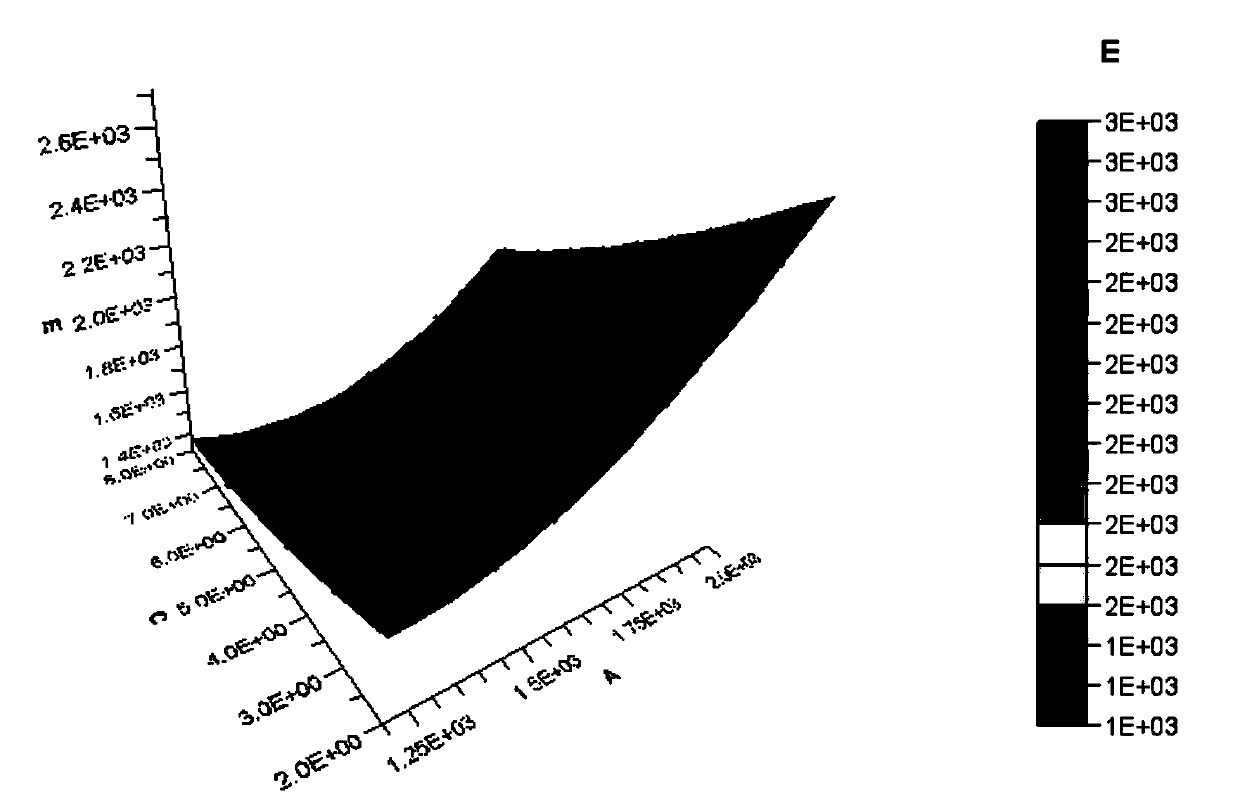

[0019] S1. Sampling: The optimal Latin hypercube is used to sample the test samples, and the laser power, welding speed, defocus and spot spacing are selected as the influencing factors of the process parameters, among which the laser power is 1200-2000w, the welding speed is 25-35mm / s, The defocus amount is 2-8mm, and the spot distance is 0.3-0.9mm. The sampling data are shown in Table 1 below.

[0020] S2. Simulation: Use the finite volume method software FLUENT to perform numerical simulation of the molten pool flow of dissimilar metals under different process parameters in step S1, in which the double-rotating Gaussian heat source model is used to represent the double-beam laser heat source, and the udf and the corresponding boundar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com