Modified glass steel bar applied for reinforcing concrete as well as preparation method and application of modified glass steel bar

A technology for reinforcing concrete and steel bars, which is applied in the field of building materials, can solve problems such as imperfect structures and properties, and achieve the effects of improving corrosion resistance and water seepage resistance, increasing tensile strength and bending strength, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of embodiment 1 thermosetting glass reinforcement

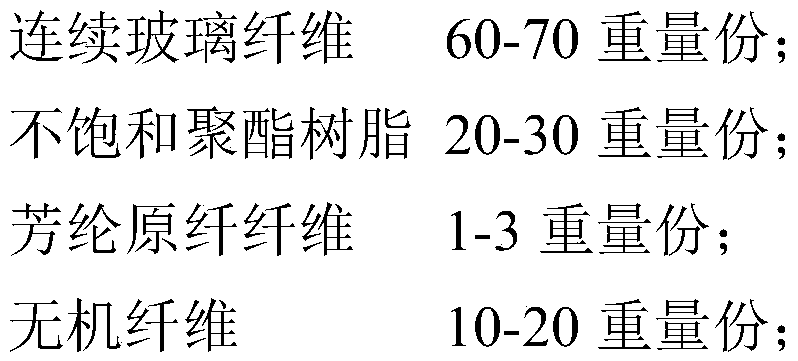

[0046] Get 60 parts by weight of untwisted glass fiber filaments, impregnate 20 parts by weight of unsaturated polyester, in the impregnated unsaturated polyester, also add 1 part by weight of aramid pulp, 10 parts by weight of wollastonite filler (preferably acicular wollastonite). The impregnated untwisted glass fiber filaments are continuously extruded and pultruded, and then cut to obtain glass steel bars of required length. The tensile strength of the obtained FRP can reach 200MPa, and the bending strength can reach 300MPa.

Embodiment 2

[0047] The preparation of embodiment 2 thermosetting glass reinforcement

[0048] Take 70 parts by weight of untwisted glass fiber filaments, impregnate 30 parts by weight of unsaturated polyester, and add 3 parts by weight of aramid pulp and 20 parts by weight of attapulgite filler to the impregnated unsaturated polyester. The impregnated untwisted glass fiber filaments are continuously extruded and pultruded, and then cut to obtain glass steel bars of required length. The tensile strength of the obtained glass reinforced steel can reach 400MPa, and the bending strength can reach 400MPa.

Embodiment 3

[0049] Embodiment 3 Preparation of thermoplastic glass reinforcement

[0050] Use 63 parts by weight of untwisted glass fiber filaments, impregnate 26 parts by weight of unsaturated polyester, in the impregnated unsaturated polyester, also add 2 parts by weight of aramid pulp, 13 parts by weight of calcium carbonate filler, 6 parts by weight 1 part of molten polypropylene resin, prepare the glass fiber impregnated with polypropylene resin by a process similar to Example 1, the glass fiber content is 60%, the tensile strength can reach 700MPa, and the flexural strength can reach 500MPa, under infrared or laser conditions Bundled into glass reinforcement, used to prepare glass reinforcement / steel hybrid reinforced concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com