Predehydration process of methyl chloride

A methyl chloride and pre-dehydration technology, applied in the preparation of halogenated hydrocarbons, the disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., can solve the problems of foaming, TEG pollution and deterioration, affecting the smooth operation of the dehydration process, etc., and achieve the regeneration cycle. prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

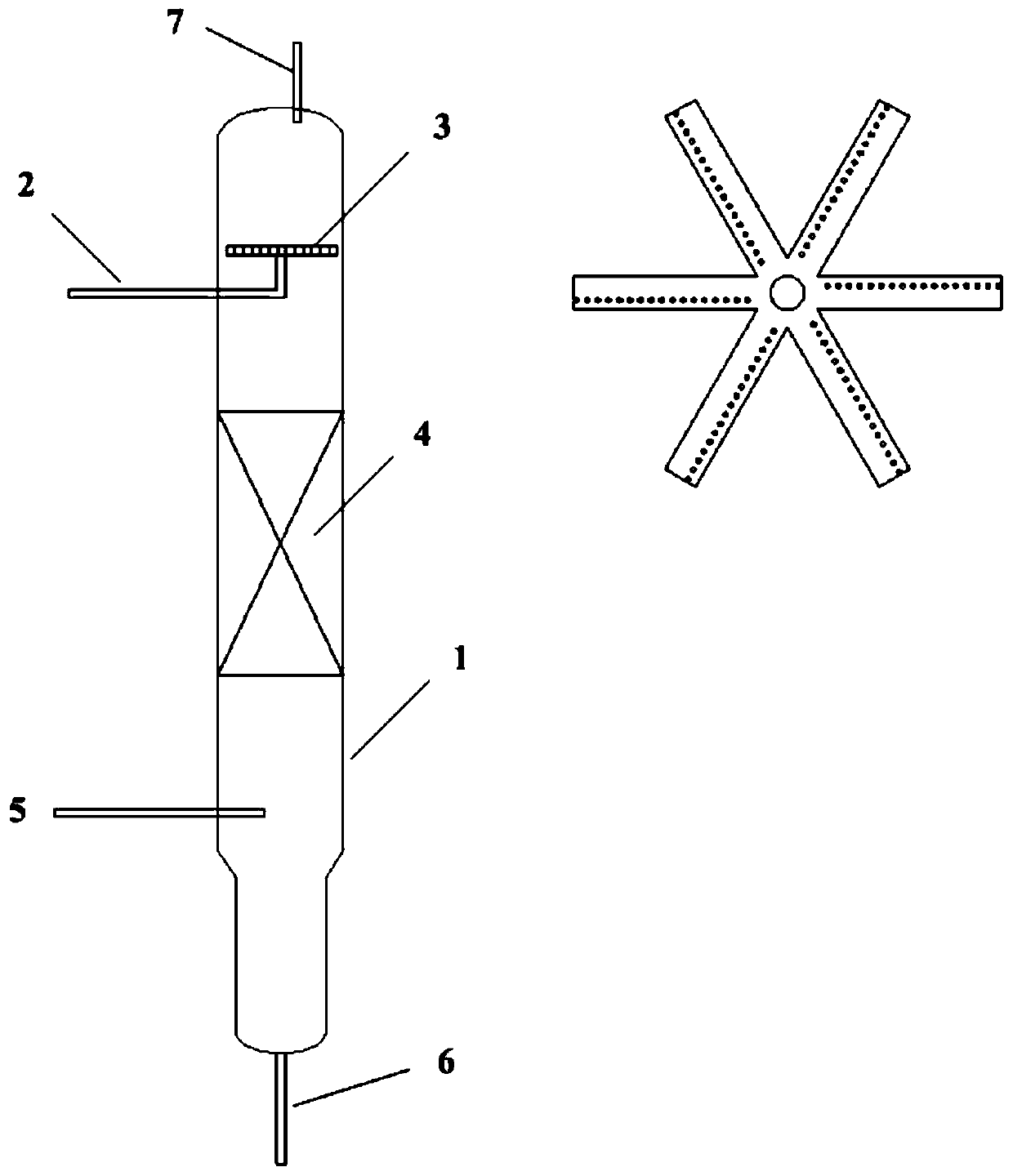

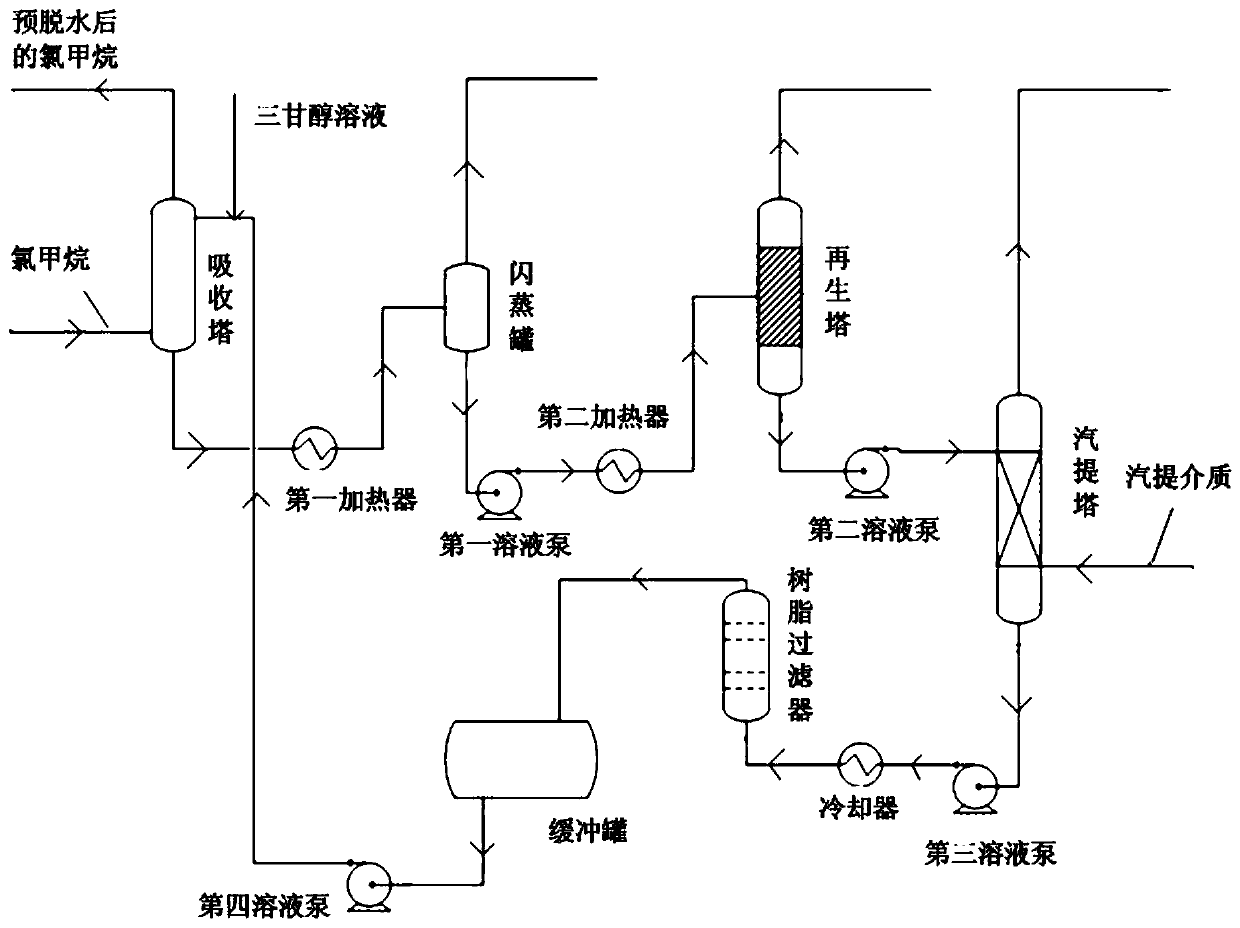

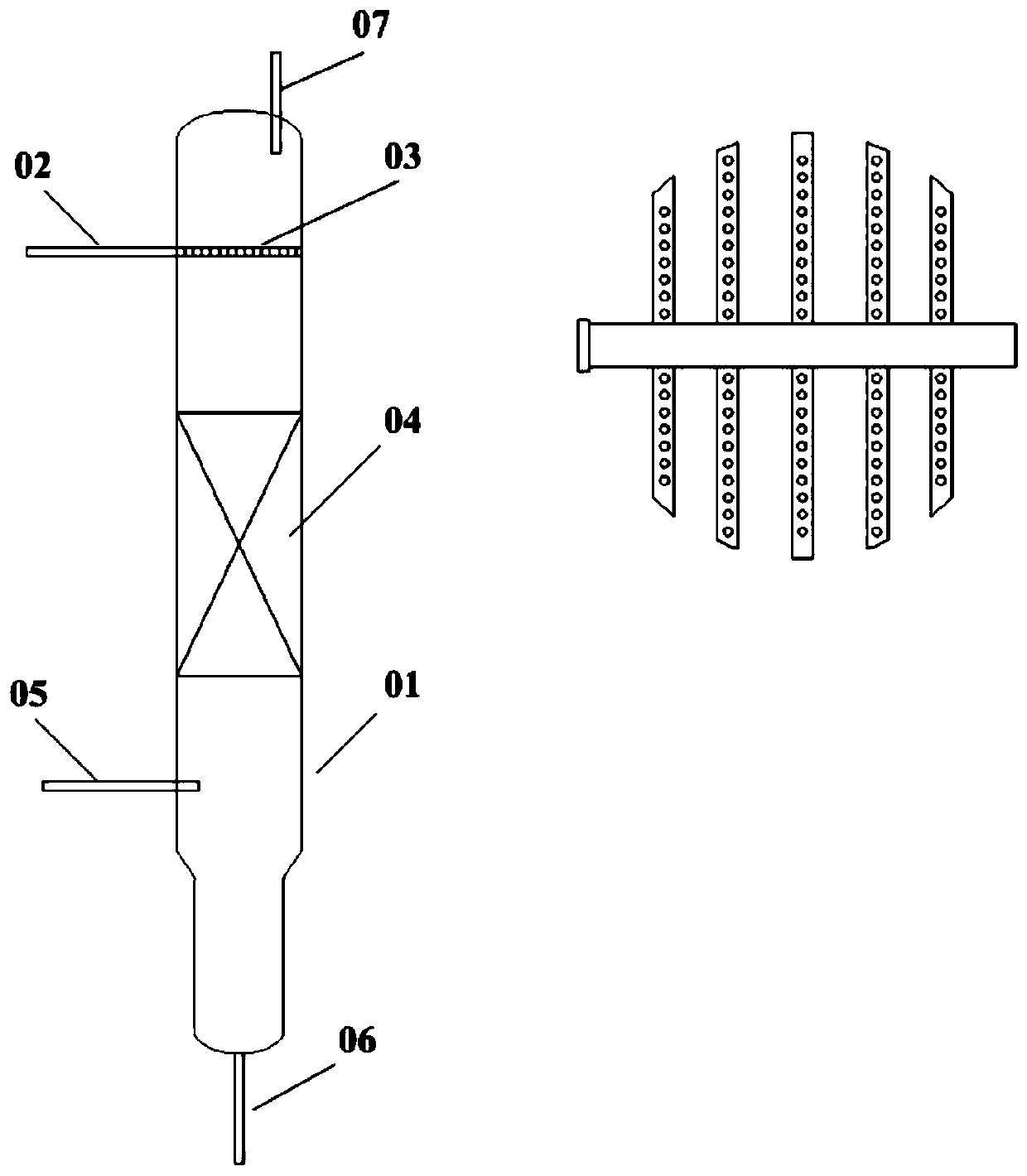

[0079] Methyl chloride (flow rate 20t / h, water content 2800ppm) that needs dehydration enters the absorption tower from the tower bottom of the absorption tower (using such as figure 1 Absorption tower shown), triethylene glycol solution (purity is 99%, flow rate 2.5t / h, pressure is 500kpa, temperature is 30 ℃) enters absorption tower by the tower top of absorption tower, and both are on the packing surface in absorption tower Countercurrent contacting completes the pre-dehydration of methyl chloride, and the pre-dehydrated methyl chloride is discharged from the top of the absorption tower and enters the subsequent dehydration process. The rich liquid that has absorbed water is discharged from the rich liquid outlet at the bottom of the absorption tower. The rich liquid after contact and absorption is heated to 70°C in the first heater, then enters the flash tank, and flashes at 70°C, part of the moisture in the rich liquid and part of the absorbed methyl chloride are converte...

Embodiment 2

[0090] Methyl chloride (flow 30t / h, water content 2800ppm) that needs dehydration enters the absorption tower from the tower bottom of the absorption tower (using such as figure 1 Shown absorption tower), triethylene glycol solution (purity is 99%, flow rate 3t / h, pressure is 500kpa, and temperature is 30 ℃) enters absorption tower by the tower top of absorption tower, and both countercurrents in the packing surface in absorption tower contact, thereby completing the pre-dehydration of methyl chloride, and the pre-dehydrated methyl chloride is discharged from the top of the absorption tower and enters the subsequent dehydration process. The rich liquid that has absorbed water is discharged from the rich liquid outlet at the bottom of the absorption tower. The rich liquid after contact and absorption is heated to 90°C in the first heater, then enters the flash tank, and flashes at 90°C, part of the water in the rich liquid and part of the absorbed methyl chloride are converted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com