Biodegradable composite material and preparation method thereof

A composite material and biodegradation technology, applied in the field of biodegradable composite materials and their preparation, can solve problems such as insufficient flame retardant performance and poor degradation, and achieve the effects of improving flame retardant performance, improving mechanical properties, and improving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

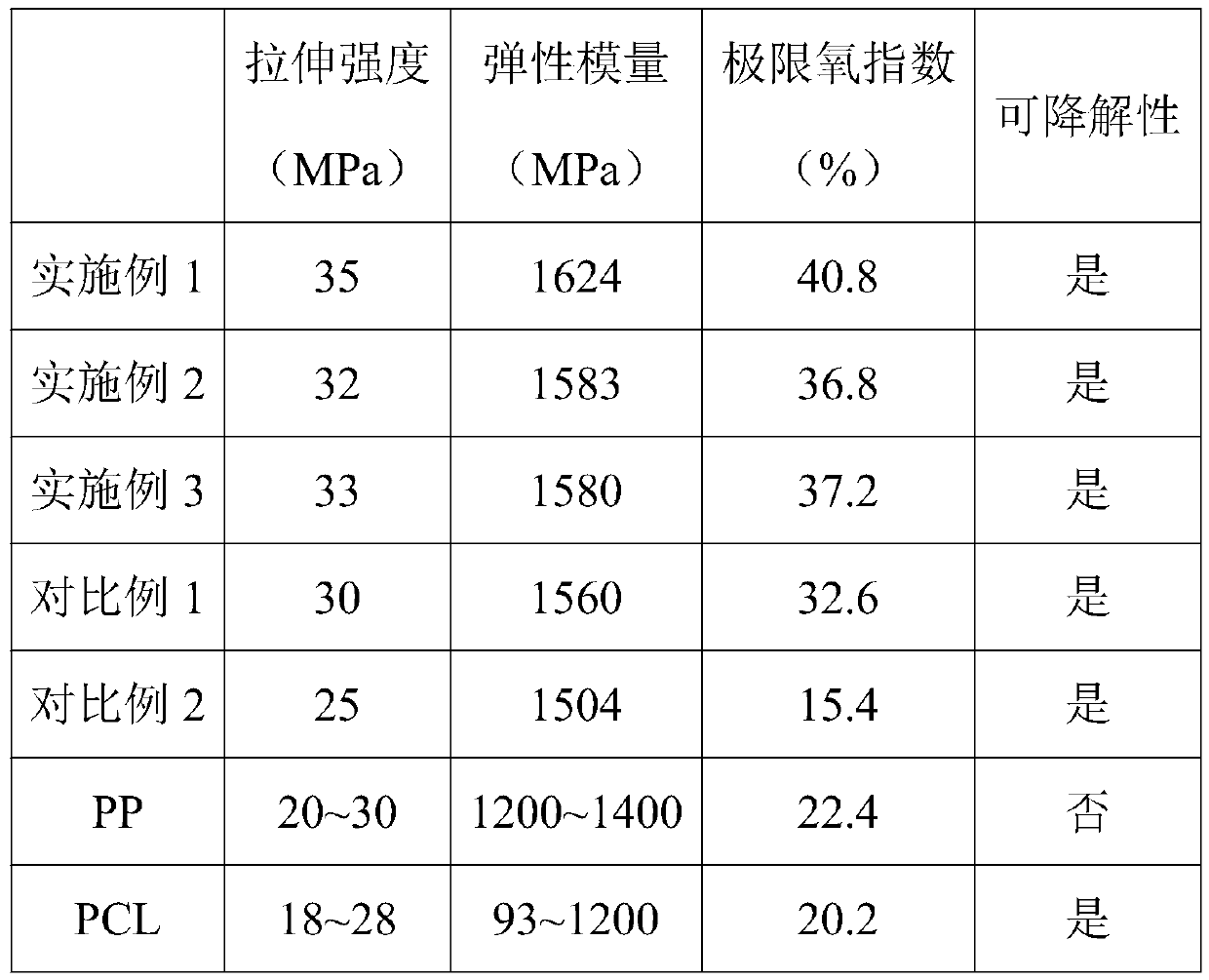

Examples

Embodiment 1

[0026] A biodegradable composite material, comprising the following components by weight:

[0027] 70 parts of polylactic acid, 10 parts of starch, 5 parts of 50-mesh bamboo charcoal powder, 5 parts of 200-mesh bamboo charcoal powder, 5 parts of silane coupling agent KH-5500, 5 parts of modifier, 1 part of ammonium polyphosphate, 5 parts of melamine, and 5 parts of polyethylene glycol.

[0028] Wherein, the preparation method of modifying agent is as follows:

[0029] Mix starch and acetic anhydride at a molar ratio of 5:0.5, stir and react for 60 minutes, and then wash the product with absolute ethanol.

[0030] The preparation method of the above-mentioned biodegradable composite material comprises the following steps:

[0031] (1) modifier and 50 mesh bamboo charcoal powder are melted and mixed according to the formula, and set aside;

[0032] (2) Dry the ammonium polyphosphate and melamine respectively at 95°C for 4 hours, and mix them evenly after cooling to room tempe...

Embodiment 2

[0035] A biodegradable composite material, comprising the following components by weight:

[0036] 80 parts of polylactic acid, 15 parts of starch, 8 parts of 100-mesh bamboo charcoal powder, 5 parts of 300-mesh bamboo charcoal powder, 10 parts of titanate, 10 parts of modifier, 5 parts of ammonium polyphosphate, 15 parts of melamine, and polyethylene glycol Alcohol 10 parts.

[0037] Wherein, the preparation method of modifying agent is as follows:

[0038] Mix starch and acetic anhydride at a molar ratio of 10:0.1, stir and react for 30 minutes, and then wash the product with absolute ethanol.

[0039] The preparation method of the above-mentioned biodegradable composite material comprises the following steps:

[0040] (1) According to the formula, the modifier is mixed with 100 mesh bamboo charcoal powder for subsequent use;

[0041] (2) Dry the ammonium polyphosphate and melamine at 150°C for 8 hours respectively, and then mix them evenly after cooling to room temperatu...

Embodiment 3

[0044] A biodegradable composite material, comprising the following components by weight:

[0045] 70 parts of polylactic acid, 12 parts of starch, 5 parts of 80-mesh bamboo charcoal powder, 3 parts of 260-mesh bamboo charcoal powder, 3 parts of silane coupling agent KH-5500, 6 parts of modifier, 2 parts of ammonium polyphosphate, 10 parts of melamine, and 6 parts of polyethylene glycol.

[0046] Wherein, the preparation method of modifying agent is as follows:

[0047] Mix starch and acetic anhydride at a molar ratio of 5:3, stir and react for 30 minutes, and then wash the product with absolute ethanol.

[0048] The preparation method of the above-mentioned biodegradable composite material comprises the following steps:

[0049] (1) modifier and 80 mesh bamboo charcoal powder are melted and mixed according to the formula, and set aside;

[0050] (2) Dry the ammonium polyphosphate and melamine respectively at 150°C for 4 hours, and mix them evenly after cooling to room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com