Preparation method of scandium tungstate/yttrium oxide composite fluorescent temperature sensing material

A technology for sensing materials and composite fluorescence, which can be used in color-changing fluorescent materials, thermometers with physical/chemical changes, luminescent materials, etc. It can solve problems such as poor thermal stability, limited application, and thermal quenching of fluorescence, and achieve high absolute sensitivity. , the preparation method is simple, the effect of fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

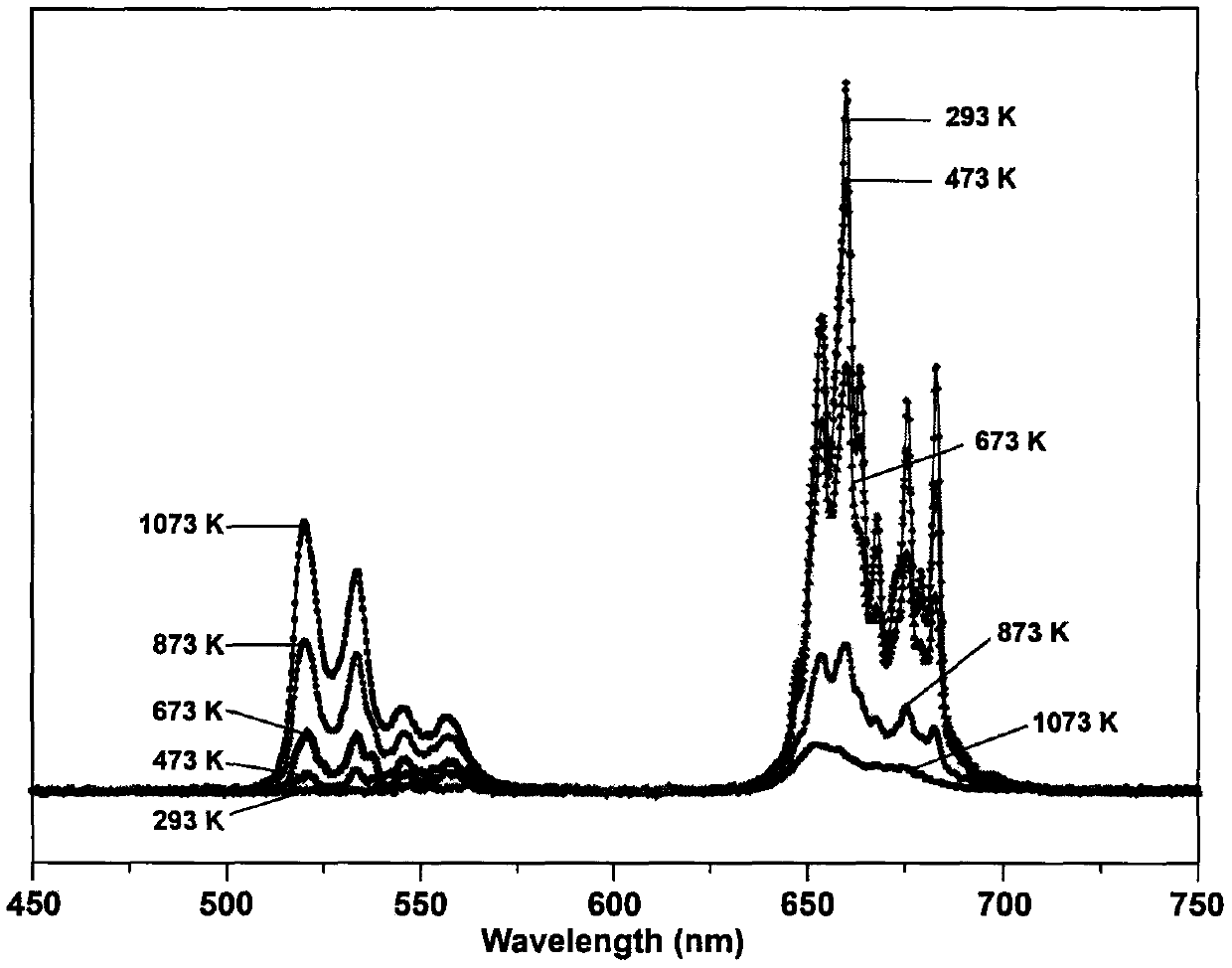

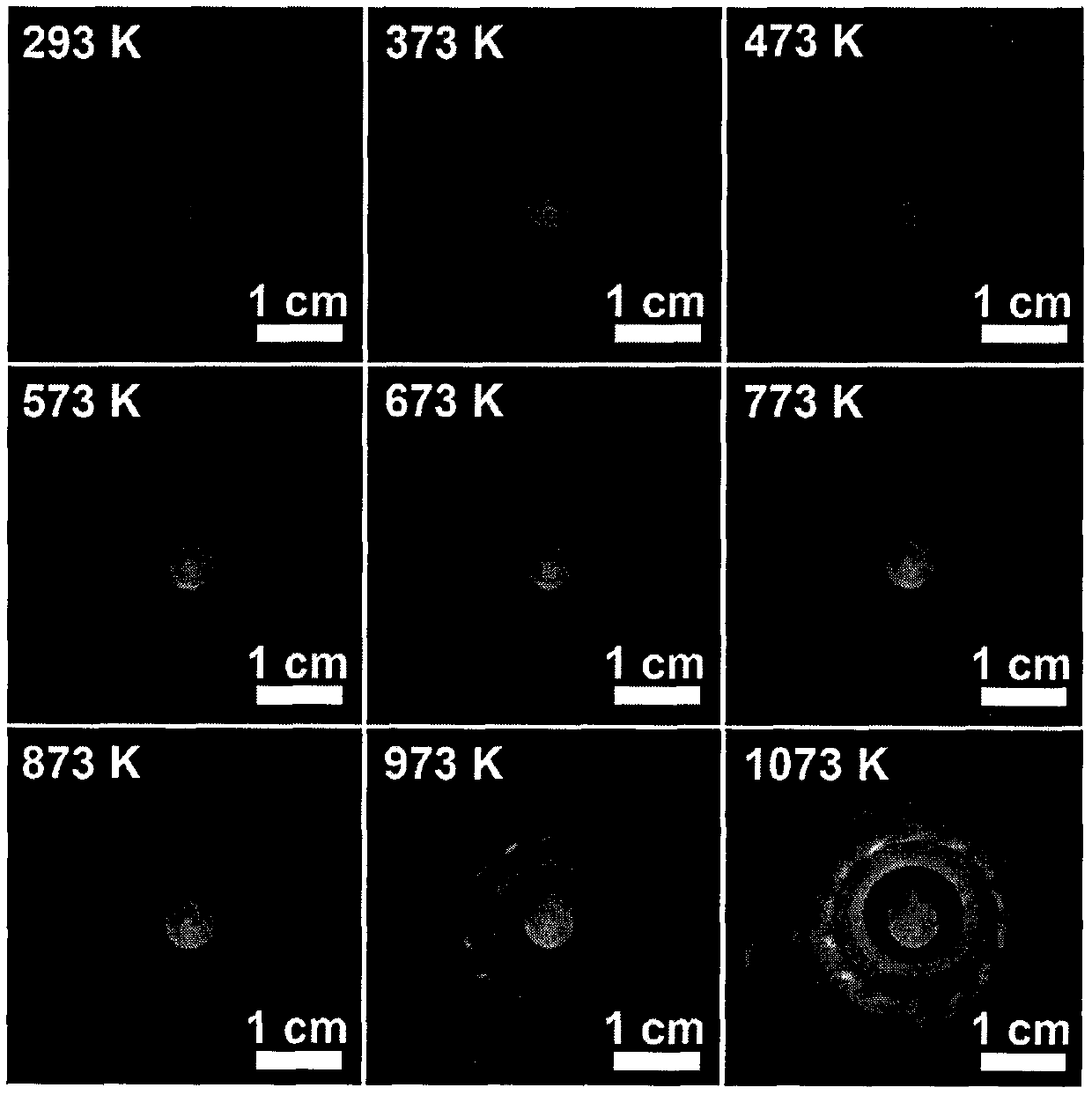

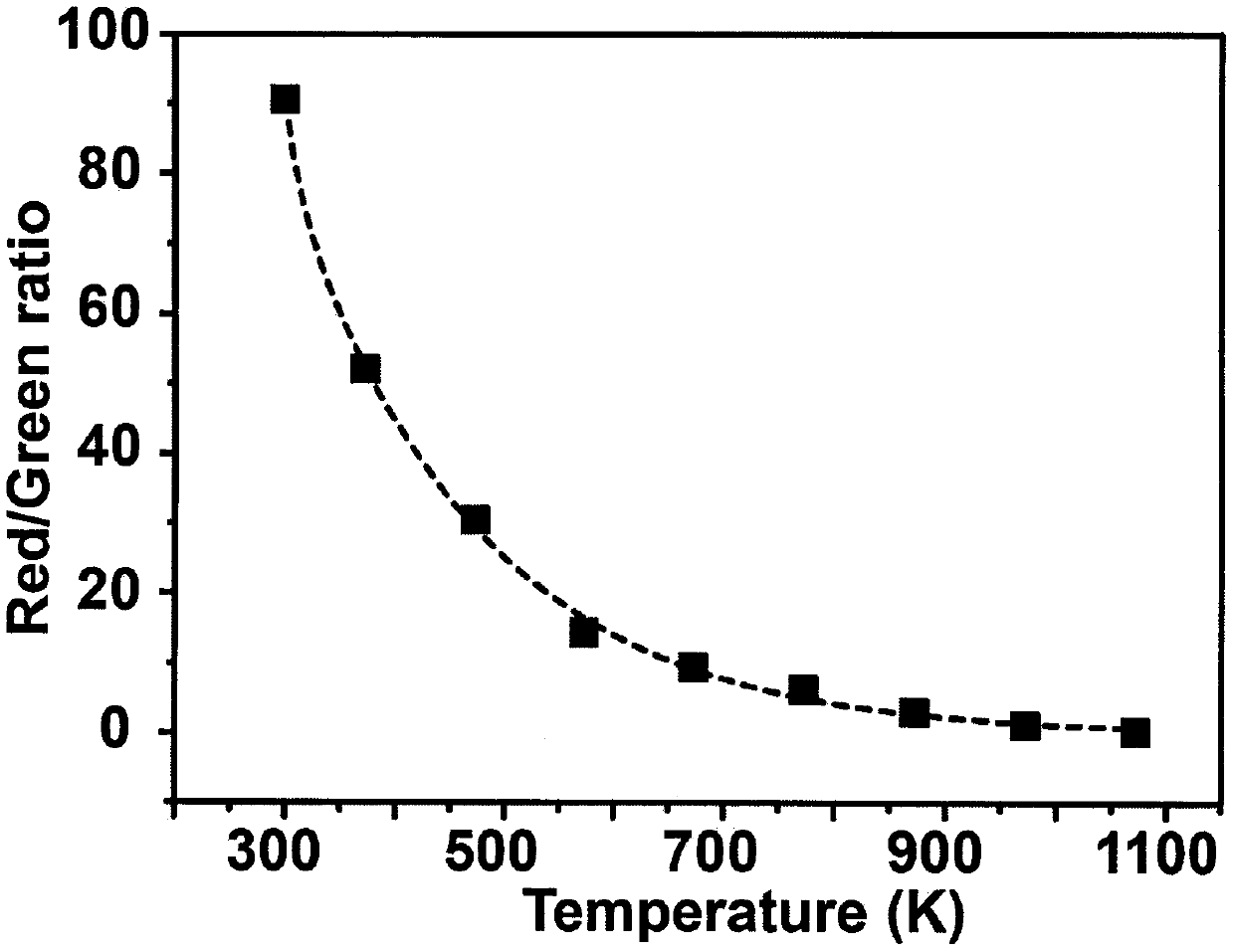

[0028] Weigh 3mmol (0.2128g) WO 3 , 0.8mmol (0.1103g) Sc 2 o 3 , 0.18mmol (0.0709g) Yb 2 o 3 and 0.02mmol (0.0077g) Er 2 o 3 In a mortar, add a small amount of ethanol and grind until all the ethanol is volatilized, repeat three times to make the powder evenly mixed. Then pour the sample into a corundum crucible and react in a muffle furnace at 1100°C for 12 hours. After the reaction is completed and the temperature is lowered to room temperature, grind the sample, grind it evenly, put it into the muffle furnace for refiring, and sinter at 1100°C for 12 hours to obtain Sc 2 (WO 4 ) 3 : Yb 3+ / Er 3+ , after grinding for later use. 1.6mmol (0.6128g) Y (NO 3 ) 3 ·6H 2 O, 0.36mmol (0.1617g) Yb (NO 3 ) 3 ·5H 2 O and 0.04mmol (0.0185g) Er(NO 3 ) 3 ·5H 2 O was added to a 50mL beaker, 20mL of deionized water was added to form a solution, and then excess NaOH was added under strong magnetic stirring, and the stirring was continued for 24h. Centrifuge and wash the ob...

Embodiment 2

[0030] Weigh 3mmol (0.2128g) WO 3 , 0.8mmol (0.2304g) Sc 2 (CO 3 ) 3 , 0.18mmol (0.0947g) Yb 2 (CO 3 ) 3 and 0.02mmol (0.0103g) Er 2 (CO 3 ) 3 In a mortar, add a small amount of ethanol and grind until all the ethanol is volatilized, repeat three times to make the powder evenly mixed. Then pour the sample into a corundum crucible and react in a muffle furnace at 1100°C for 12 hours. After the reaction is completed and the temperature is lowered to room temperature, grind the sample, grind it evenly, put it into the muffle furnace for refiring, and sinter at 1100°C for 12 hours to obtain Sc 2 (WO 4 ) 3 : Yb 3+ / Er 3+ , after grinding for later use. 1.6mmol (0.6128g) Y (NO 3 ) 3 ·6H 2 O, 0.36mmol (0.1617g) Yb (NO 3 ) 3 ·5H 2 O and 0.04mmol (0.0185g) Er(NO 3 ) 3 ·5H 2 O was added to a 50mL beaker, 20mL of deionized water was added to form a solution, and then excess NaOH was added under strong magnetic stirring, and the stirring was continued for 24h. Centr...

Embodiment 3

[0032] Weigh 3mmol (0.2128g) WO 3 , 0.8mmol (0.1103g) Sc 2 o 3 , 0.18mmol (0.0709g) Yb 2 o 3 and 0.02mmol (0.0077g) Er 2 o 3 In a mortar, add a small amount of ethanol and grind until all the ethanol is volatilized, repeat three times to make the powder evenly mixed. Then pour the sample into a corundum crucible and react in a muffle furnace at 1100°C for 12 hours. After the reaction is completed and the temperature is lowered to room temperature, grind the sample, grind it evenly, put it into the muffle furnace for refiring, and sinter at 1100°C for 12 hours to obtain Sc 2 (WO 4 ) 3 : Yb 3+ / Er 3+ , after grinding for later use. 1.6mmol (0.5604g) Y (CH 3 COO) 3 , 0.36mmol (0.1520g) Yb (CH 3 COO) 3 and 0.04mmol (0.0119g) Er(CH 3 COO) 3 Add it into a 50mL beaker, add 20mL deionized water to form a solution, then add excess NaOH under strong magnetic stirring, and keep stirring for 24h. Centrifuge and wash the obtained white powder with deionized water and absol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com