Energy dissipation and vibration reduction corrugated steel tube-rubber concrete assembly type pier and method

A technology of rubber concrete and corrugated steel pipe, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of difficult steel structure and concrete, anti-collision design of difficult bridge piers, small application scope, etc. capacity, the effect of improving the quality of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

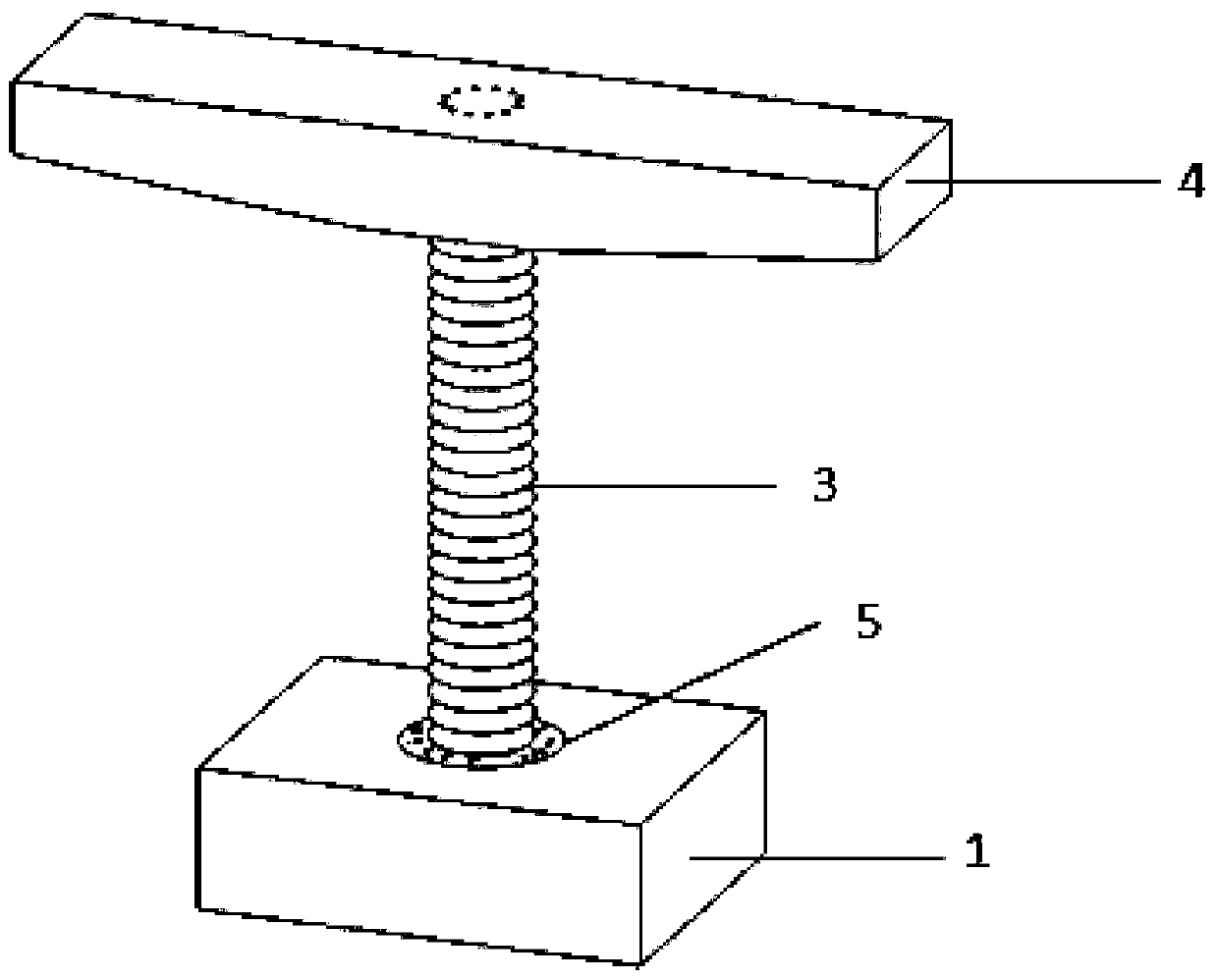

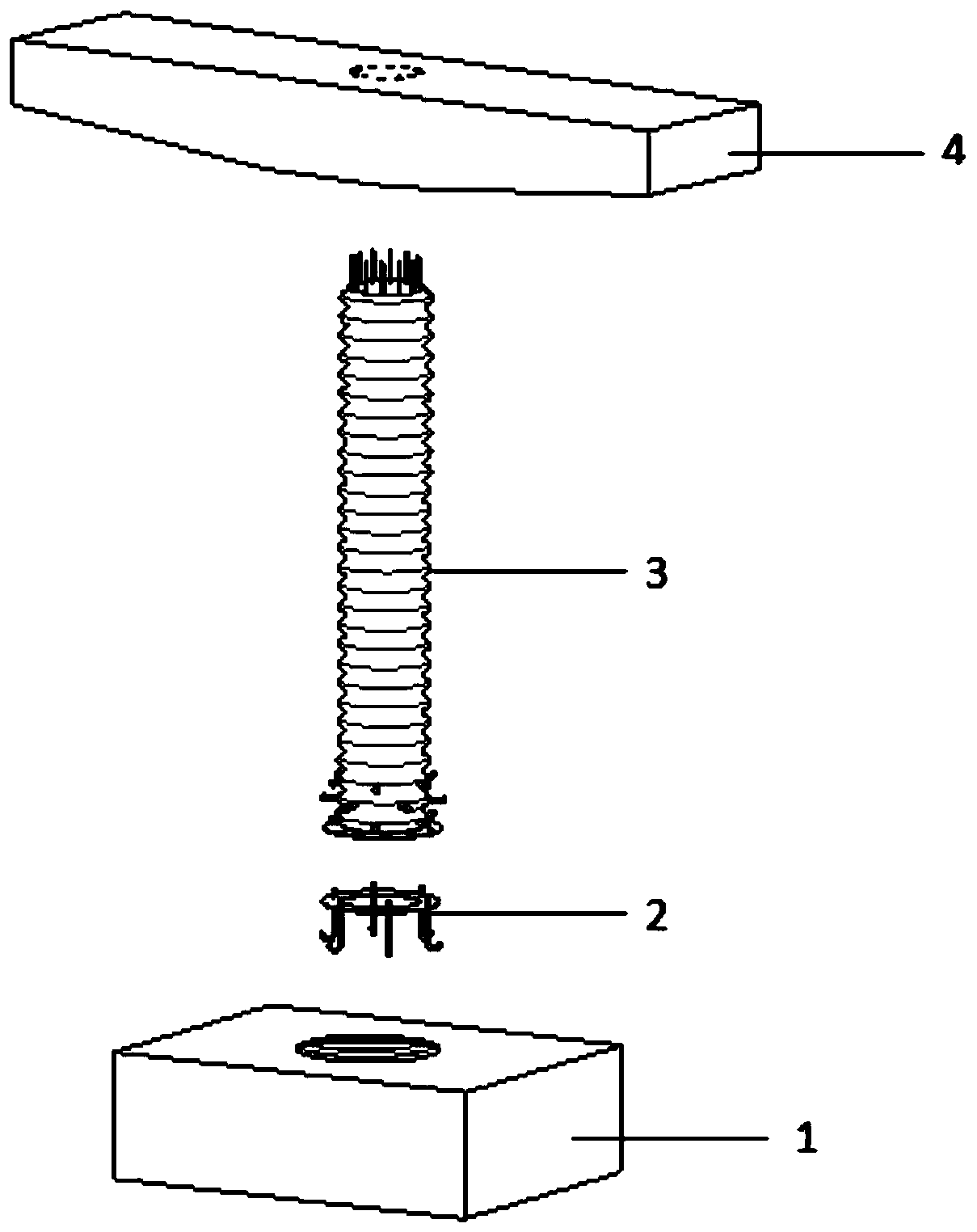

[0037] In a typical implementation of the present application, such as Figure 1-Figure 3 As shown, a corrugated steel pipe-rubber concrete fabricated bridge pier with energy dissipation and shock absorption is proposed.

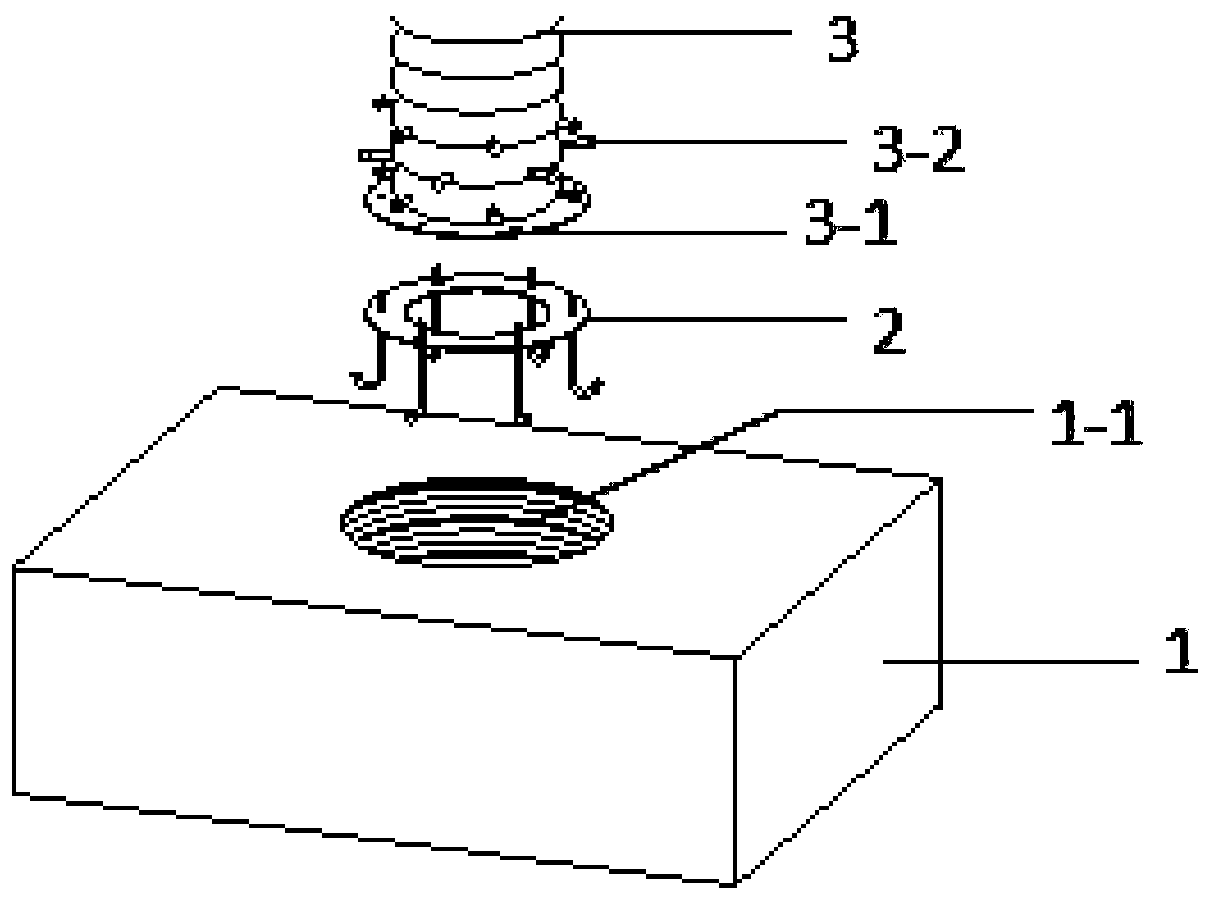

[0038] It includes a bearing platform 1, a supporting column 3, and a cover beam 4. A first flange is provided between the bearing platform and the supporting column, and a plurality of fixed steel bars 2 are fitted in the ring direction of the first flange. One end is buried in the cap, and the other end passes through the second flange 3-1 preset at the lower end of the support column to connect the cap and the support column. The interior of the support column is provided with longitudinal reinforcement, and the upper end of the longitudinal reinforcement extends out of the support On the top surface of the column, the cover beam is provided with a channel corresponding to the upper end of the longitudinal steel bar. The cover beam is installed on the suppo...

Embodiment 2

[0052] In another typical embodiment of the present application, a construction method for the energy-dissipating and shock-absorbing corrugated steel pipe-rubber concrete fabricated bridge pier described in Embodiment 1 is provided.

[0053] Filling construction, pouring caps, reserved pouring opening:

[0054] When pouring the cap, the radius of the reserved groove opening on the top surface of the cap is slightly larger than that of the composite pier;

[0055] Embedded first flange and fixed reinforcement:

[0056] The first flange is a ring-shaped steel plate, and the fixed steel bars include six ribbed steel bars. The six ribbed steel bars pass through the holes reserved in the ring-shaped steel plate for a certain distance and are welded. The other end of the ribbed steel bars is bent outward; embedded in the groove Flange hooks to ensure its vertical verticality and horizontal position;

[0057] Hoisting, positioning composite piers and pouring notches:

[0058] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com